| DN | Length | Axial displacement | Lateral displacement | ||

| (MM) | (Inch) | (MM) | Extension | Compression | (MM) |

| 32 | 1.25 | 90 | 5-6 | 10 | 10 |

| 40 | 1.6 | 95 | 5-6 | 10 | 10 |

| 50 | 2 | 105 | 5-6 | 10 | 10 |

| 65 | 2.6 | 115 | 5-6 | 10 | 10 |

| 80 | 3.2 | 135 | 5-6 | 10 | 10 |

| 100 | 4 | 150 | 10 | 18 | 14 |

| 125 | 5 | 165 | 10 | 18 | 14 |

| 150 | 6 | 180 | 10 | 18 | 14 |

| 200 | 8 | 210 | 14 | 22 | 20 |

| 250 | 10 | 230 | 14 | 22 | 20 |

| 300 | 12 | 245 | 14 | 22 | 20 |

| 350 | 14 | 255 | 14 | 22 | 20 |

| 400 | 16 | 255 | 14 | 22 | 20 |

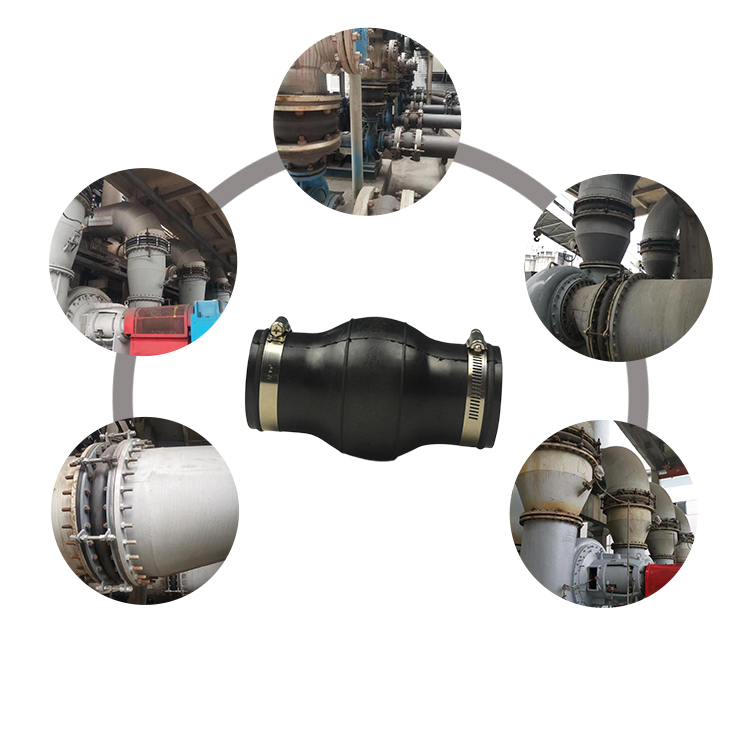

Clamp Type Rubber Expansion Joint

Looking for a high-quality Clamp Type Rubber Expansion Joint? Look no further than our factory! We produce top-of-the-line products that meet all your needs. Shop now and experience quality like never before!

Request a QuotePRODUCTS DETAILS

Hot Products

Threaded Connection Rubber Expansion Joint

FDZ Straight Pipe Air Duct Expansion Joit

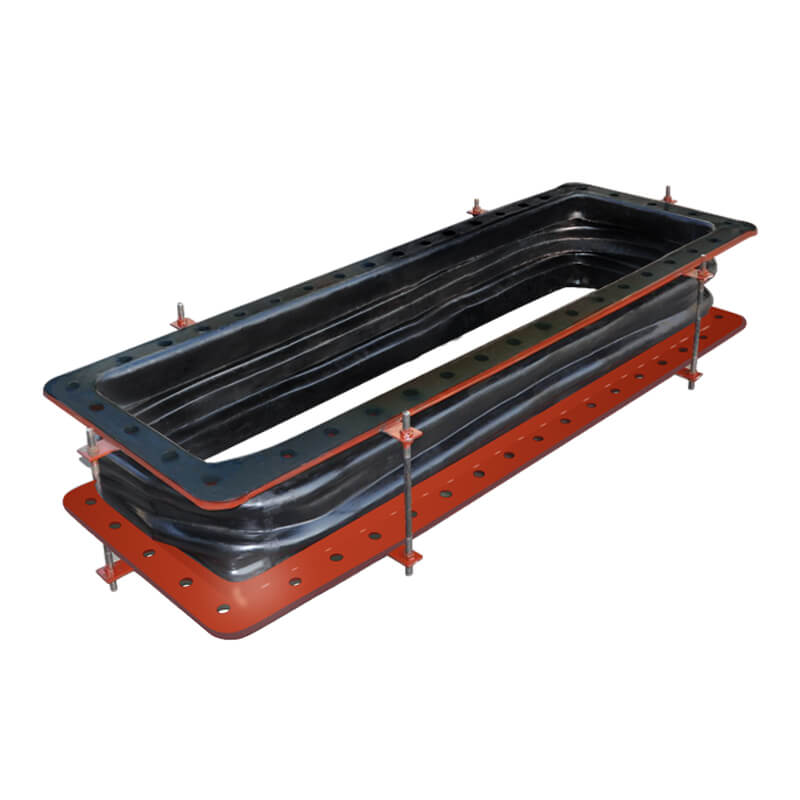

Rectangular Corrugated Compensator

Spool Type Rubber Expansion Joints

XB Air Duct Fabric Expansion joint(Round)

Dismantling Metal Expansion Joint

VSSJA-1 Single Flange Limit Metal Expansion Joint

XB Air Duct Fabric Expansion Joint(Rectangle)

Eccentric Reducing Rubber Joints

Clamp Type Rubber Expansion Joint

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours