Understanding the Specifications of Rubber Expansion Bellows

By:Admin

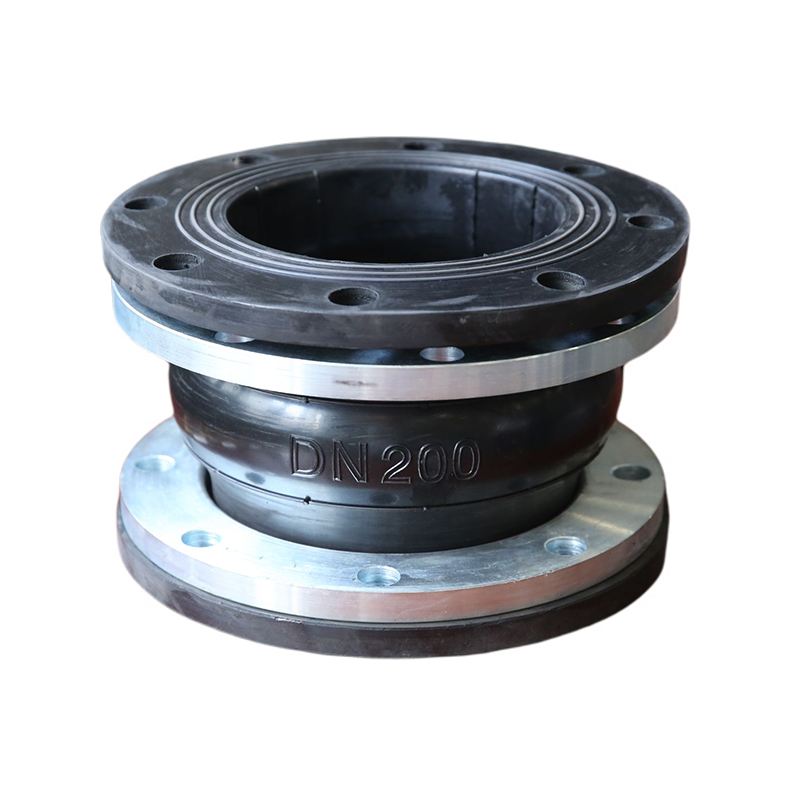

Expanding its product line, leading industry player {Company Name} has recently unveiled its latest innovation in rubber expansion bellows. With an aim to cater to the diverse needs of its customers, the new range of rubber expansion bellows is set to revolutionize various industries, providing enhanced flexibility, durability, and reliability.

Featuring a range of sizes and specifications, the rubber expansion bellows offered by {Company Name} are meticulously designed and manufactured to withstand extreme temperatures, pressures, and corrosive environments. These bellows are primarily used to absorb thermal expansion in piping systems, compensating for a variety of axial, lateral, and angular movements.

In order to provide the highest level of performance, {Company Name} has integrated state-of-the-art technology and industry-leading materials into the construction of these bellows. Each rubber expansion bellow is made from premium quality rubber compounds, ensuring excellent resistance to abrasion, chemicals, and ozone. This not only prolongs the lifespan of the bellows but also minimizes the risk of leaks, failures, and downtime.

Moreover, {Company Name} has taken into consideration the ease of installation and maintenance. The rubber expansion bellows are designed to be lightweight and flexible, making them easy to handle during installation and inspection. Their modular design allows for quick and hassle-free replacement, reducing downtime and maximizing productivity.

The new range of rubber expansion bellows offered by {Company Name} complies with international standards and certifications, ensuring the highest level of quality and reliability. These bellows are thoroughly tested to meet or exceed industry requirements, providing customers with peace of mind and confidence in their performance.

The application of rubber expansion bellows spans across various industries, including but not limited to, chemical processing, heavy machinery, power plants, HVAC systems, and water treatment facilities. With their superior flexibility, these bellows effectively absorb vibrations and shocks, preventing damage to the piping system and improving overall safety.

Furthermore, {Company Name} understands the importance of customization to meet the specific needs of its clients. As a result, the company offers tailored solutions through its team of experienced engineers and technicians. They work closely with customers to analyze their requirements and provide customized rubber expansion bellows that perfectly fit their applications.

With its vast experience and expertise, {Company Name} has established itself as a reliable and trusted name in the rubber expansion bellow industry. The company is renowned for its commitment to delivering superior products, excellent customer service, and competitive pricing.

In line with its dedication to environmental sustainability, {Company Name} ensures that its rubber expansion bellows are manufactured using eco-friendly practices and materials. By adhering to strict quality control measures, the company minimizes waste production and energy consumption, contributing to a greener and cleaner future.

In conclusion, the launch of the new range of rubber expansion bellows by {Company Name} marks another milestone in the company's growth and commitment to meeting the evolving needs of its customers. With their impressive specifications, durability, and customization options, these bellows have the potential to revolutionize various industries, ensuring optimal performance and reliability for crucial piping systems.

Company News & Blog

Free PNG and SVG Pipe Joint Illustrations and Vector Images in 45 Styles

Pipes are an essential part of our everyday life, from carrying water to transporting gas. However, these pipes cannot function without joints that connect them together. Joints for pipes come in various shapes and sizes, and they are essential for the seamless functioning of our plumbing systems.One common type of joint for pipes is the clip joint. A clip joint is a joining method that involves using a clip or clamp to secure two pieces of pipe together. Clip joints are easy to install and do not require any special tools or expertise. They are commonly used in household plumbing applications such as sink and shower installations.Clip joints come in various materials, including PVC, copper, and stainless steel. These materials are chosen based on the application and the environment in which the joint will be used. For example, PVC clip joints are suitable for low-pressure applications such as drainage systems, while stainless steel clip joints are ideal for high-pressure applications such as gas pipelines.To ensure the proper functioning of clip joints, it is crucial to choose the right size and type of clip for the pipe. Improperly sized or mismatched clips can result in leaks, which can lead to water damage and flooding. It is also important to use high-quality clips from reputable manufacturers to ensure durability and longevity.When installing clip joints, it is essential to follow proper installation procedures. This includes ensuring that the pipes are clean and dry, and that the clip is tightened to the manufacturer's specifications. Failure to follow proper installation procedures can result in leaks, which can compromise the overall integrity of the plumbing system.In summary, joints for pipes, such as clip joints, are essential for the proper functioning of our plumbing systems. It is crucial to choose the right size and type of clip for the pipe and to follow proper installation procedures. With the right joints and installation techniques, we can ensure the seamless functioning of our plumbing systems and avoid water damage and other plumbing issues.Keywords: Joints for Pipes, Clip joints, PVC clip joints, Copper clip joints, Stainless steel clip joints, Plumbing systems, Pipe Joint Clipart Illustrations & Images, PNG, SVG.

High Density Flexible Connectors: A Necessity for High-Speed and High-Reliability Interconnections

Flexible connectors have become increasingly important in modern electronics, as high speed and high I/O systems require matched impedance interconnections with high density and reliability. In particular, the transition from logic to optical interfaces has created a need for new connector solutions that can accommodate the demands of these systems.One solution that has emerged in recent years is the High Density Flexible Connector, or HDFC. This technology is designed to provide a high level of performance in a compact form factor that can be integrated into a variety of systems. The HDFC uses a series of flexible circuit boards to create a flexible, high density connector that can accommodate large numbers of signals, while maintaining a high level of reliability and signal integrity.One notable feature of the HDFC is its ability to handle signal speeds of up to 20 Gbps. This is accomplished through the use of advanced materials and manufacturing techniques that enable the creation of extremely thin conductive traces with excellent signal transmission characteristics. The result is a flexible connector that can transmit large amounts of data at high speeds, without sacrificing reliability or signal quality.Another key advantage of the HDFC is its ability to maintain consistent signal impedance across large numbers of connections. This is essential for high speed and high I/O systems, which require tightly controlled impedance to ensure proper signal transmission. The HDFC achieves this through careful design and testing, which ensures that the connector maintains the correct impedance characteristics even when large numbers of connections are made.One specific application of the HDFC is in the area of double sphere flexible connectors. These connectors are used in a variety of applications, including robotics, assembly lines, and other high-speed manufacturing processes. Double sphere connectors require a high level of flexibility and reliability in order to accommodate the movement and vibration that is common in these environments.The HDFC is well-suited to this application, as it provides an extremely flexible and reliable connection that can be easily integrated into existing systems. The double sphere design of the connector allows for a wide range of motion and flexibility, while maintaining a high level of electrical performance.In summary, the High Density Flexible Connector is a powerful solution that can provide high speed, high density, and high reliability interconnections for a variety of modern systems. With its advanced materials, manufacturing techniques, and careful design, the HDFC is well-suited to handle the demanding needs of modern electronics, including the transition to optical interfaces and the need for double sphere flexible connectors. If you are looking for a flexible connector for your high-speed system, the HDFC may be the right choice for you.

New Pump Bellows Connectors Offer Improved Seal for Safe Industrial Operations

Title: Pump Bellows Connectors: Providing Efficient and Reliable Solutions for the IndustryIntroduction:In today's fast-paced industrial landscape, the efficiency and reliability of machinery and components are crucial for seamless operations. One such integral component is the Pump Bellows Connector, a vital innovation that ensures optimal functioning of pumps in various industries. This article delves into the significance of Pump Bellows Connectors and highlights the noteworthy contributions of a renowned manufacturing company in this field.I. Understanding Pump Bellows Connectors:Pump Bellows Connectors are flexible, expansion joints designed to absorb vibrations, compensate for thermal expansion, and reduce stress on piping systems. These connectors act as a link between the pump and the pipeline, allowing for movement and expansion while maintaining a tight seal. Their flexibility and versatility make them an indispensable component for various industries, including oil and gas, chemical processing, water treatment, and power generation.II. The Role of Pump Bellows Connectors:1. Absorbing Vibrations: Pump vibrations can lead to machinery damage and reduced equipment lifespan. Pump Bellows Connectors effectively dampen vibrations, minimizing system stress and enabling quieter operations. This feature translates into fewer maintenance needs and enhanced equipment longevity.2. Compensating for Thermal Expansion: Piping systems often experience thermal expansion due to the temperature variations in industrial processes. By accommodating these movements, Pump Bellows Connectors prevent stress, cracks, and leaks in the system. This ability to compensate for thermal expansion ensures the uninterrupted flow of fluids, preventing potential disruptions and failures.3. Reducing Stress on Piping Systems: Pump Bellows Connectors serve as a flexible joint between the pump and the piping system. This flexibility allows for the absorption of movements caused by misalignment, pump vibrations, or thermal expansion. As a result, stress on pipes and associated connections is greatly reduced, minimizing the risk of leaks and maintaining system integrity.III. The Leading Manufacturer:[List the brand name] is a reputable manufacturer with a proven track record in providing high-quality Pump Bellows Connectors. With a commitment to innovation and customer satisfaction, [Brand Name] has become a trusted name in the industry. Their team of experts combines extensive knowledge with cutting-edge technology to deliver connectors that meet and exceed industry standards.1. Quality Assurance: [Brand Name] employs stringent quality control measures throughout the manufacturing process. Each Pump Bellows Connector undergoes rigorous inspections and testing to ensure its durability, reliability, and compliance with industry specifications. The company's dedication to quality has earned them a solid reputation among industry professionals.2. Customization and Efficiency: Recognizing the diverse needs of different industries, [Brand Name] offers customized solutions for specific applications. The company's team of skilled engineers works closely with clients to design Pump Bellows Connectors that precisely meet their requirements. This tailored approach ensures optimal performance, reduced maintenance, and enhanced efficiency in every application.IV. Benefits and Applications:1. Benefits of Pump Bellows Connectors: Pump Bellows Connectors provide numerous benefits, including improved system performance, extended equipment life, reduced maintenance costs, and enhanced safety. The usage of these connectors leads to increased productivity, decreased downtime, and enhanced overall productivity for various industrial processes.2. Applications: Pump Bellows Connectors find extensive applications in a wide range of industries. They are commonly used in chemical plants, power generation facilities, oil refineries, water treatment plants, and pharmaceutical facilities. Their versatility allows for seamless integration into different systems, making them an essential component in ensuring efficient and reliable operations.V. Conclusion:Pump Bellows Connectors play a critical role in maintaining the efficiency, reliability, and safety of industrial machinery and piping systems. As seen through the contributions of [Brand Name], the manufacturing of these connectors requires precision and expertise. With continuous innovation and a commitment to customer satisfaction, [Brand Name] has established itself as a leading provider of high-quality Pump Bellows Connectors, serving a wide array of industries effectively.

Rubber Flexible Bellows Help Extend Machinery Lifespan" can be rewritten as "Flexible Rubber Bellows Increase Machinery Longevity".

Rubber Flexible Bellows: The Innovative Solution to Your Piping NeedsPiping systems are crucial elements of various applications, including power plants, chemical industries, and manufacturing plants. These systems enable the transportation of liquids, gases, and solids from one point to another, making them vital to industrial processes. However, piping systems are also prone to a range of damages that can significantly affect their efficiency and safety. One common issue among piping systems is the lack of flexibility, which can lead to damages due to thermal expansion, vibration, and misalignment. Fortunately, the innovative Rubber Flexible Bellows has emerged as a solution to these challenges.Flexible bellows are tube-like structures with accordion-like folds that allow the absorption of thermal movement and vibrations. These structures are critical components of piping systems, enabling a range of motion that reduces the likelihood of damages and malfunctions. Rubber Flexible Bellows, in particular, have become popular among industrial players due to their durability, flexibility, and ability to withstand various environmental conditions. They are designed to withstand extreme temperatures, chemicals, and pressure, making them versatile for various settings and applications.One company that has been at the forefront of Rubber Flexible Bellows production is [company name]. The company, established in [year], has gained a reputation for producing high-quality and dependable bellows that meet the diverse needs of industrial players. Its team of competent engineers and technicians specializes in designing, manufacturing, and supplying bellows for various applications, including power plants, pharmaceuticals, food industries, and HVAC systems.At the core of the company's operations is its commitment to providing innovative solutions that are both efficient and cost-effective. The Rubber Flexible Bellows produced by the company offers a range of benefits, including:1. Enhanced Safety - Piping systems are prone to damages that can lead to leaks, explosions, and other hazardous events. Rubber Flexible Bellows provide an added layer of safety, enabling the efficient transportation of fluids while minimizing the risk of damages and malfunctions.2. Reduced Maintenance Costs - Traditional piping systems require regular maintenance and repairs, which can be costly and time-consuming. Rubber Flexible Bellows reduce the need for maintenance, enabling industrial players to save on repair costs and downtime.3. Enhanced Efficiency - Bellows enable piping systems to absorb thermal expansion, vibrations, and misalignments, thus reducing the likelihood of damages and malfunctions. This leads to enhanced efficiency and productivity, enabling industrial players to achieve their production goals efficiently.4. Versatility - Rubber Flexible Bellows can be customized to meet the unique needs of various applications, making them versatile for various settings and industries.In addition to its innovative Rubber Flexible Bellows products, [company name] also prides itself on its exceptional customer service. The company's team of experts is dedicated to providing personalized solutions that meet the specific needs of each client. They work closely with clients to understand their unique needs, providing tailored products that exceed their expectations.In conclusion, Rubber Flexible Bellows have become an innovative solution to the challenges faced by piping systems in various industries. These structures offer a range of benefits, including enhanced safety, reduced maintenance costs, enhanced efficiency, and versatility. As such, they have become an essential component of various applications, including power plants, chemical industries, and manufacturing facilities. [Company name] has established itself as a leader in Rubber Flexible Bellows production, offering high-quality and dependable products that meet the diverse needs of industrial players. Its commitment to innovation, efficiency, and exceptional customer service makes it a reliable partner for all your piping needs.

Suppliers of Bellows, Compensators, and Silicone Rubber Seals with Authentic Customer Reviews

Looking for reliable bellows suppliers? Look no further than one of the most trusted names in the industry – a leader in designing and manufacturing top-quality bellows, compensators, and silicone rubber seals that are used in a broad range of industrial applications.With years of experience in the industry, we have developed a reputation for excellence and reliability, thanks to our commitment to providing our customers with nothing but the best. Our product line is extensive, and we are confident that we have the perfect solution to meet your needs.As one of the leading bellows suppliers in the industry, we take great pride in our ability to deliver products that offer exceptional performance and long-lasting durability. Our products are designed to withstand the harsh environments and demanding conditions that are often found in industrial applications, ensuring that you can rely on them to get the job done.Our range of products includes everything from bellows and compensators to silicone rubber seals, all of which are designed to meet the highest standards of quality and performance. We use only the best materials and techniques to manufacture our products, ensuring that they are built to last and can withstand even the toughest conditions.Whether you are looking for a custom solution or something off-the-shelf, we have the expertise and experience to deliver the perfect product for your needs. We work closely with our customers to understand their specific requirements and to develop solutions that are tailored to their unique needs.In addition to our extensive range of products, we also offer unbeatable customer service and support. We are always available to answer your questions and provide technical advice, ensuring that you have all the information and support you need to make the right decision for your business.So if you are looking for a reliable bellows supplier that you can trust, look no further than one of the most respected names in the industry. With our commitment to quality, innovation, and customer satisfaction, we are the partner you need to help your business thrive. Contact us today to learn more!

When it comes to piping systems, flexible connectors such as single sphere rubber expansion joints are crucial components. These devices are designed to connect piping sections while providing flexibility for movement and vibration isolation. In this blog, we will explore the features, benefits, and applications of the single sphere rubber expansion joint.The single sphere rubber expansion joint is made of two flanges with a rubber sphere in between. The flanges can be made of various materials such as carbon steel, stainless steel, or PVC. The rubber sphere is typically made of EPDM, Nitrile, or Neoprene, depending on the application requirements.One of the most significant benefits of a single sphere rubber expansion joint is its ability to absorb movement and vibration. When a piping system is in operation, it may experience thermal expansion and contraction, vibration, and other movements. These movements can cause stress on the piping system, leading to fatigue and failure. The single sphere rubber expansion joint can absorb these movements, reducing stress on the system and increasing the longevity of the piping.Another benefit of a single sphere rubber expansion joint is that it can compensate for misalignment and offset. When two piping sections are not in perfect alignment, the single sphere rubber expansion joint can compensate for the difference, reducing stress and preventing leaks.Single sphere rubber expansion joints are used in various industries, including HVAC, water treatment, chemical processing, and power generation. In HVAC systems, these flexible connectors are used to absorb vibrations caused by pumps, fans, and compressors. In water treatment plants, they are used to compensate for thermal expansion and contraction caused by changes in water temperature. In chemical processing plants, they are used to absorb movements caused by the flow of chemicals. In power generation plants, they are used to absorb movements caused by the vibration of turbines and generators.In conclusion, the single sphere rubber expansion joint is a crucial component of piping systems. Its ability to absorb movement and vibration, compensate for misalignment and offset, and its versatility make it an ideal choice for a wide range of applications. If you are looking for a reliable and cost-effective solution for your piping system, consider the single sphere rubber expansion joint.

Prominent Rubber Joint Flange: An Insight into this Essential Component

Rubber Joint Flange (RJF) is a leading manufacturer of industrial rubber products that are designed to meet the most demanding requirements of modern industries. The company has over three decades of experience in the field and is known for its expertise in product design, development, and manufacturing processes. With a wide range of products, RJF serves customers across various industries, including construction, mining, transportation, and oil and gas.The company's product portfolio includes rubber joints, expansion bellows, flexible connectors, and other rubber products. These products are made of high-quality materials that are tested rigorously for durability, strength, and resistance to extreme temperatures and pressures. In addition, RJF's products can be customised to meet the specific requirements of individual clients.RJF's products are widely used in a variety of industries due to their numerous advantages. For example, rubber joints are used in piping systems to absorb vibrations and reduce noise, while expansion bellows are used to compensate for thermal expansion and contraction, preventing damage to pipelines. Similarly, flexible connectors are used to connect two different pipes or tubes, without compromising the integrity of the system.RJF's products are known for their robust construction and long-lasting performance, attributes that have helped the company establish a loyal customer base. The company has a dedicated team of experts who are committed to providing the best customer service and support. They work closely with customers to understand their specific needs and offer personalised solutions.RJF also has a strong focus on innovation and research. The company's research and development (R&D) team work tirelessly to identify new materials and technologies that can enhance product performance and user experience. The company invests heavily in R&D to ensure that its products remain at the cutting edge of the industry.Recently, RJF launched a new product called the Rubber Expansion Joint. This product features a unique design that allows for low spring rates, higher movements, and lower forces at low pressures. The Rubber Expansion Joint is ideal for applications where high levels of movement are expected, such as in pipelines and piping systems. This product has received positive feedback from customers, who have praised its reliability, durability, and ease of installation.In addition to designing and manufacturing high-quality rubber products, RJF is committed to sustainability and social responsibility. The company strives to reduce its carbon footprint and minimise waste by using eco-friendly materials and processes. RJF is also committed to producing products that are safe for use by employees and customers.RJF has received several awards and accolades for its pioneering work in the industry. the company has won the prestigious ISO 9001 certification for its quality management system, as well as the ISO 14001 certification for its environmental management system.In conclusion, Rubber Joint Flange is a leading manufacturer of industrial rubber products, with a strong focus on innovation, research, and sustainability. The company's products are known for their robust construction, long-lasting performance, and customisation options. With a dedicated team of experts and a commitment to customer service, RJF is well-positioned to meet the evolving needs of its customers in various industries.

Understanding the Specifications of Rubber Expansion Bellows

Rubber Expansion Bellow SpecificationExpanding its product line, leading industry player {Company Name} has recently unveiled its latest innovation in rubber expansion bellows. With an aim to cater to the diverse needs of its customers, the new range of rubber expansion bellows is set to revolutionize various industries, providing enhanced flexibility, durability, and reliability.Featuring a range of sizes and specifications, the rubber expansion bellows offered by {Company Name} are meticulously designed and manufactured to withstand extreme temperatures, pressures, and corrosive environments. These bellows are primarily used to absorb thermal expansion in piping systems, compensating for a variety of axial, lateral, and angular movements.In order to provide the highest level of performance, {Company Name} has integrated state-of-the-art technology and industry-leading materials into the construction of these bellows. Each rubber expansion bellow is made from premium quality rubber compounds, ensuring excellent resistance to abrasion, chemicals, and ozone. This not only prolongs the lifespan of the bellows but also minimizes the risk of leaks, failures, and downtime.Moreover, {Company Name} has taken into consideration the ease of installation and maintenance. The rubber expansion bellows are designed to be lightweight and flexible, making them easy to handle during installation and inspection. Their modular design allows for quick and hassle-free replacement, reducing downtime and maximizing productivity.The new range of rubber expansion bellows offered by {Company Name} complies with international standards and certifications, ensuring the highest level of quality and reliability. These bellows are thoroughly tested to meet or exceed industry requirements, providing customers with peace of mind and confidence in their performance.The application of rubber expansion bellows spans across various industries, including but not limited to, chemical processing, heavy machinery, power plants, HVAC systems, and water treatment facilities. With their superior flexibility, these bellows effectively absorb vibrations and shocks, preventing damage to the piping system and improving overall safety.Furthermore, {Company Name} understands the importance of customization to meet the specific needs of its clients. As a result, the company offers tailored solutions through its team of experienced engineers and technicians. They work closely with customers to analyze their requirements and provide customized rubber expansion bellows that perfectly fit their applications.With its vast experience and expertise, {Company Name} has established itself as a reliable and trusted name in the rubber expansion bellow industry. The company is renowned for its commitment to delivering superior products, excellent customer service, and competitive pricing.In line with its dedication to environmental sustainability, {Company Name} ensures that its rubber expansion bellows are manufactured using eco-friendly practices and materials. By adhering to strict quality control measures, the company minimizes waste production and energy consumption, contributing to a greener and cleaner future.In conclusion, the launch of the new range of rubber expansion bellows by {Company Name} marks another milestone in the company's growth and commitment to meeting the evolving needs of its customers. With their impressive specifications, durability, and customization options, these bellows have the potential to revolutionize various industries, ensuring optimal performance and reliability for crucial piping systems.

Latest Update: An Insight into the Rubber Flex Connector - All You Need to Know

Rubber Flex Connector: Revolutionizing Industrial Connections[City], [State] - In a world of constant innovation and technological advancements, industries are constantly searching for ways to improve efficiency and functionality. This search has led to the development of a groundbreaking product called the Rubber Flex Connector, which is changing the way industries connect and transmit materials. With its unparalleled flexibility, durability, and reliability, the Rubber Flex Connector has emerged as a game-changer in the field and is quickly becoming a preferred choice for a wide range of applications.The Rubber Flex Connector is manufactured by a renowned company that specializes in engineering high-quality industrial solutions. With decades of experience and expertise under their belt, this company has become a trusted name in providing innovative solutions to various industries. Their commitment to excellence and customer satisfaction has enabled them to stay ahead of the competition and deliver products that set new standards in the industry.One of the key features that sets the Rubber Flex Connector apart from traditional connectors is its exceptional flexibility. This connector is made from a specially formulated rubber compound that allows it to bend and twist without compromising its integrity. Industries such as HVAC, plumbing, and automotive have long struggled to find connectors that can accommodate the complex movements and vibrations inherent in their operations. The Rubber Flex Connector solves this problem by providing a reliable connection that can flex and adapt to changing conditions, reducing the risk of leaks, cracks, and other failures.Durability is another crucial aspect of the Rubber Flex Connector. Unlike traditional connectors that may degrade over time due to exposure to harsh chemicals, extreme temperatures, or mechanical stress, the Rubber Flex Connector is designed to withstand the harshest conditions. Its robust construction and high-quality materials ensure that it can resist corrosion, abrasion, and impact, extending its lifespan significantly. This durability translates into substantial cost savings for industries, as they can reduce maintenance and replacement costs associated with frequent connector failures.Moreover, the Rubber Flex Connector offers unmatched reliability. With its advanced sealing technology, this connector provides a tight and secure connection that prevents leaks and ensures efficient material transmission. This reliability is particularly crucial for industries that deal with hazardous materials or require a sterile environment, such as pharmaceuticals or food processing. By minimizing the risk of contamination or leakage, the Rubber Flex Connector plays a vital role in maintaining the safety and integrity of these operations.Not only does the Rubber Flex Connector excel in performance, but it also offers versatility in its applications. With a wide range of sizes, configurations, and connection types available, industries can easily find the perfect match for their specific needs. Whether it's connecting pipes in plumbing systems, linking ducts in HVAC units, or joining components in automotive assemblies, the Rubber Flex Connector provides a flexible and adaptable solution that streamlines operations and enhances overall efficiency.Moreover, the company behind the Rubber Flex Connector is committed to sustainable practices and environmental responsibility. They have implemented several initiatives to reduce their carbon footprint by using eco-friendly materials, optimizing production processes, and recycling waste. By choosing the Rubber Flex Connector, industries can contribute to a greener future while enjoying the benefits of a premium-quality product.In conclusion, the Rubber Flex Connector is revolutionizing industrial connections with its exceptional flexibility, durability, and reliability. This groundbreaking product, manufactured by a trusted company, provides a solution to the long-standing challenges faced by various industries. With its ability to withstand harsh conditions, tight and secure sealing, and wide range of applications, the Rubber Flex Connector is proving to be a game-changer in the field. As industries strive for efficiency and superior performance, the Rubber Flex Connector is undoubtedly leading the way towards a more connected and sustainable future.