Rubber Bellows Expansion Joints: What You Need to Know

By:Admin

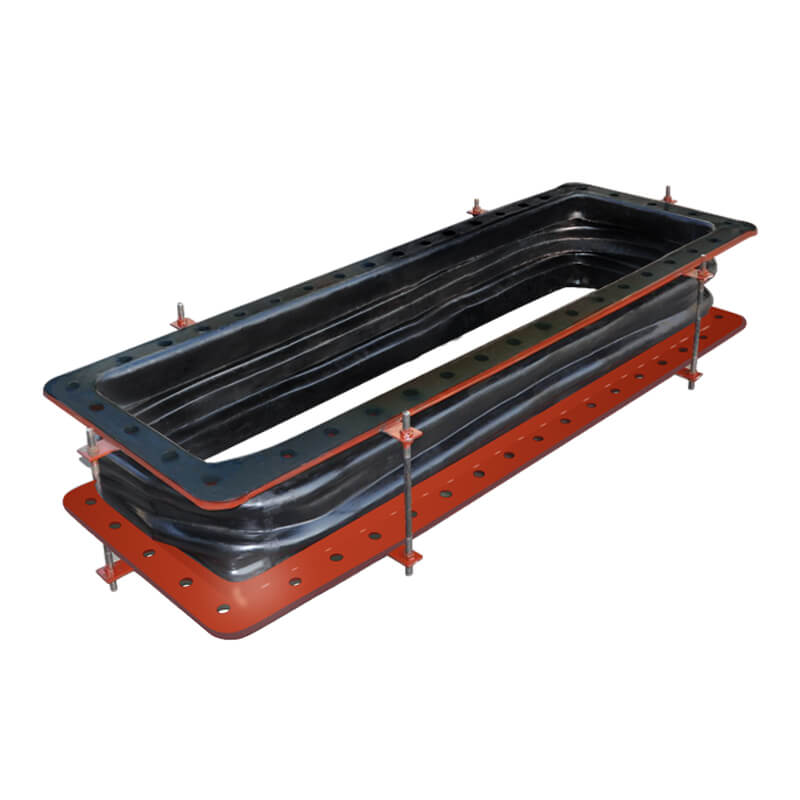

The [Company Name] Rubber Bellows Expansion Joints are manufactured using the latest technology and adhere to the highest industry standards. This ensures that they are able to withstand the most demanding operating conditions, including high temperatures, corrosive chemicals, and extreme pressure. The use of rubber bellows in the design allows for greater flexibility and movement, making them ideal for use in piping systems that experience thermal expansion and contraction.

One of the key advantages of the [Company Name] Rubber Bellows Expansion Joints is their ability to reduce vibration and noise in piping systems. This is achieved through the use of specially engineered rubber compounds that absorb and dampen vibration, resulting in a quieter and smoother operation. In addition, the unique bellows design allows for greater flexibility and movement, which helps to reduce stress and fatigue on piping systems, ultimately extending their lifespan.

In addition to their superior performance, the [Company Name] Rubber Bellows Expansion Joints are also designed with ease of installation and maintenance in mind. The lightweight and flexible nature of the expansion joints make them easier to handle and install, saving time and labor costs. Furthermore, the use of high-quality materials and precision manufacturing processes ensures that these expansion joints require minimal maintenance, resulting in lower overall operating costs for our customers.

The launch of the Rubber Bellows Expansion Joints is a testament to [Company Name]'s commitment to providing innovative solutions to the industrial market. With decades of experience in the industry, [Company Name] has built a reputation for excellence and reliability, and the introduction of these expansion joints only solidifies that reputation. Our customers can have full confidence in the performance and quality of these products, knowing that they are backed by a company with a proven track record of delivering exceptional products and services.

[Company Name] is confident that the Rubber Bellows Expansion Joints will have a significant impact on the industrial market, offering a solution that meets the ever-evolving needs of our customers. Whether it's in the petrochemical, power generation, water treatment, or HVAC industries, these expansion joints are poised to deliver unparalleled performance and reliability. With their ability to reduce vibration and noise, withstand harsh operating conditions, and require minimal maintenance, these expansion joints are sure to become an essential component in a wide range of piping systems.

As part of the launch of the Rubber Bellows Expansion Joints, [Company Name] is offering comprehensive technical support and consultation services to help customers select and integrate these expansion joints into their piping systems. Our team of experienced engineers and technical experts are available to provide guidance and assistance at every step of the process, ensuring that customers are able to maximize the benefits of these innovative products.

Overall, the launch of the Rubber Bellows Expansion Joints represents an exciting milestone for [Company Name] and the industrial market as a whole. With their advanced design, exceptional performance, and industry-leading quality, these expansion joints are set to revolutionize the way piping systems are designed and operated. Customers can expect nothing less than excellence from [Company Name], and the Rubber Bellows Expansion Joints are a clear demonstration of that commitment.

Company News & Blog

High-Quality Rubber Joint Flange for Industrial Use

Rubber Joint Flange, the leading provider of high-quality rubber products, is proud to announce the release of their latest innovation in piping technology. The new rubber joint flange is designed to provide superior performance in a wide range of industrial applications, making it an ideal solution for companies in various industries.The rubber joint flange is designed to provide flexibility and vibration isolation in piping systems, making it an essential component for maintaining the integrity and efficiency of industrial processes. The product is constructed using high-quality rubber materials that are capable of withstanding extreme pressure and temperature conditions, ensuring long-lasting performance in even the most demanding environments.Rubber Joint Flange is dedicated to providing the highest quality products to their customers, and their new rubber joint flange is no exception. The company has invested heavily in research and development to ensure that their products are at the forefront of industry standards, and the new rubber joint flange is a testament to their commitment to innovation and excellence.In addition to its superior performance, the rubber joint flange also boasts a user-friendly design that makes installation and maintenance a simple and straightforward process. This feature is particularly valuable for companies looking to minimize downtime and optimize their operations, as it allows for quick and easy maintenance of piping systems without the need for specialized tools or equipment.Furthermore, the rubber joint flange is compatible with a wide variety of piping materials, making it a versatile solution for companies working with different types of piping systems. This flexibility extends the applicability of the product across multiple industries, making it an attractive choice for companies looking to streamline their supply chain and reduce the number of unique components and materials required for their operations.Rubber Joint Flange is renowned for its dedication to customer satisfaction, and the new rubber joint flange is backed by the company's unwavering commitment to quality and reliability. The product has undergone rigorous testing and quality control measures to ensure that it meets the highest industry standards, providing customers with the peace of mind that comes with knowing they are investing in a product that is built to last.The release of the new rubber joint flange further solidifies Rubber Joint Flange's position as a leader in the rubber products industry, and the company is confident that the product will be well-received by companies seeking a reliable and versatile solution for their piping needs. With its combination of innovative design, high performance, and user-friendly features, the rubber joint flange is set to become an indispensable component for companies in various industries.Rubber Joint Flange is excited to bring this new product to the market and looks forward to continuing to meet the evolving needs of their customers. With a strong track record of delivering high-quality products and exceptional customer service, the company is well-positioned to continue leading the industry and providing innovative solutions that drive growth and success for their customers.About Rubber Joint FlangeRubber Joint Flange is a leading provider of high-quality rubber products, specializing in solutions for a wide range of industrial applications. The company is committed to delivering exceptional products and outstanding customer service, and has built a strong reputation for reliability, innovation, and excellence in the industry. With a focus on quality, performance, and customer satisfaction, Rubber Joint Flange continues to set the standard for rubber products and remains a trusted partner for companies in various industries.

Comprehensive Guide to Expansion Bellow Specifications for Industrial Applications

Expansion Bellow Specification for Improved Performance and Safety in Industrial ApplicationsDate:In today's rapidly evolving industrial sector, the demand for high-performance equipment and systems continues to grow. One crucial component that plays a significant role in ensuring the smooth functioning of various industrial processes is expansion bellows. These flexible devices are designed to absorb thermal expansion and contraction, vibrations, and misalignments in pipelines, thereby preventing damage to critical infrastructure and improving overall safety.Company Introduction{Company Name} is a leading manufacturer and supplier of expansion bellows, catering to a wide range of industries such as oil and gas, petrochemical, power generation, water treatment, automotive, and many others. With a steadfast commitment to quality, innovation, and customer satisfaction, {Company Name} has gained a reputation for delivering reliable and durable expansion bellow solutions. Employing a team of trained professionals and utilizing state-of-the-art manufacturing processes, the company ensures that its products meet the highest industry standards.Expansion Bellow Specification{Company Name} understands the diverse requirements of industrial applications and offers a comprehensive range of expansion bellows to suit various needs. The expansion bellow specification encompasses crucial design parameters and features that contribute to improved performance, longevity, and safety. Some of the key specifications are as follows:1. Material Selection: The expansion bellow material is chosen based on the specific application requirements. Common options include stainless steel, carbon steel, Hastelloy, Inconel, and other high-quality alloys. The selection is made considering factors such as temperature, pressure, corrosion resistance, and compatibility with process media.2. Size and Design: {Company Name} offers expansion bellows in a wide range of sizes and designs to accommodate different pipeline configurations. Whether it's a rectangular, circular, or other custom shapes, the company provides versatile options that can withstand high temperatures, pressures, and mechanical stress.3. Movement Capability: Expansion bellows are primarily employed to absorb movements caused by thermal expansion and contraction. The bellow specification includes parameters like axial, lateral, and angular movements to ensure that the bellows can handle the anticipated displacements in a given system.4. Pressure Ratings: To ensure structural integrity, expansion bellows must have adequate pressure ratings. {Company Name} manufactures expansion bellows with different pressure class ratings, enabling seamless integration within systems operating at varying pressures.5. Quality Testing: Prioritizing quality and reliability, {Company Name} subjects every expansion bellow to rigorous testing procedures. These include pressure tests, leak tests, fatigue cycle tests, and other non-destructive examinations to validate the performance and safety of the products.Benefits of {Company Name}'s Expansion Bellows{Company Name}'s expansion bellows offer several key benefits that make them an ideal choice for industrial applications:1. Flexibility: The expansion bellows' inherent flexibility allows them to absorb movement and minimize stress on adjoining components, thus preventing premature failure.2. Enhanced Safety: By effectively compensating for thermal expansion and contraction, expansion bellows ensure the integrity of pipelines, reduce the risk of leakage, and enhance overall operational safety.3. Improved Efficiency: Expansion bellows minimize the impact of vibration, misalignment, and thermal stresses on system components, resulting in smoother operation, increased efficiency, and reduced maintenance costs.4. Extended Lifespan: The high-quality materials and rigorous testing employed by {Company Name} contribute to the longevity of its expansion bellows, ultimately reducing the need for frequent replacements and associated downtime.ConclusionEmbracing the latest technological advancements and prioritizing customer satisfaction, {Company Name} provides expansion bellow solutions that meet the industry's demanding requirements. With a focus on safety, durability, and performance, the company ensures that its expansion bellows enable reliable operation for a wide range of industrial applications. For businesses seeking high-quality expansion bellows, {Company Name} remains a trusted and reliable partner.

Certification for Quality Fluorine Elastomer Expansion Joints with Genuine Viton

Maintenance and Durability in Heavy-duty ApplicationsWhen it comes to industrial equipment, heavy-duty applications require the strongest and most reliable materials available. This is especially important for equipment used in power stations, flue-gas desulfurization plants, and other high-stress environments that need to withstand extreme heat, pressure, and vibration. In order to ensure optimal performance and long-lasting durability, expansion joints made with elastomers have become a staple in the industry.Elastomer expansion joints are flexible connectors that are designed to absorb movements, vibrations, and stress caused by machinery and piping systems. They also protect equipment from structural damage and reduce noise and emissions. The most common types of elastomers used in expansion joints are natural rubber, neoprene, EPDM, and Viton.Viton, in particular, is a high-performance elastomer that is known for its exceptional resistance to heat, chemicals, and fluids. It is widely used in aerospace, automotive, pharmaceutical, and industrial applications, where it is critical to maintain strict quality control standards. Genuine Viton is a trademarked product of DuPont, and is recognized as the gold standard in terms of quality and reliability.Expansion joints made with genuine Viton have several advantages over other types of elastomers. Firstly, they can withstand temperatures between -20 to 204°C, making them ideal for use in extreme weather conditions. Additionally, they are highly resistant to corrosive gases and liquids, which can cause damage to other materials over time. This is especially important in power stations, where flue gases contain sulfur dioxide and other acidic compounds that can erode and degrade equipment.Another significant advantage of genuine Viton expansion joints is their exceptional durability. Unlike other elastomers that may last only a few years before needing replacement, genuine Viton expansion joints can have a working life of up to ten years or more. This means fewer replacement and maintenance costs in the long run, as well as reduced downtime and increased productivity.When selecting expansion joints for heavy-duty applications, it is important to choose a reputable manufacturer who can guarantee the quality and performance of their products. Power Engineering International Company is certified by DuPont to use genuine Viton in their flue-gas desulfurization plants, ensuring that their expansion joints meet the highest standards of reliability and durability. They are also RAL-awarded for quality and ISO 9001 certified.Maintenance of elastomer expansion joints is critical for ensuring their longevity and performance. Regular visual inspections for signs of leaks, cracks, or wear and tear are recommended, as well as periodic cleaning to remove dust, dirt, and debris. It is also essential to follow the manufacturer's instructions for installation, operation, and maintenance, to ensure optimal performance and minimize any potential sources of failure.In conclusion, elastomer expansion joints are an essential component of heavy-duty machinery and piping systems in power stations, flue-gas desulfurization plants, and other industrial applications. Genuine Viton expansion joints offer superior resistance to heat, chemicals, and fluids, as well as exceptional durability and longevity. Selecting high-quality expansion joints and following proper maintenance procedures can ensure optimal performance and minimize maintenance costs in the long run.

Durable and Flexible Rubber Pump Connector for Various Applications

Flex Connector, a leading manufacturer of industrial rubber products, has announced the launch of their new Pump Rubber Flex Connector. This innovative product is designed to provide a flexible and reliable connection between pumps and pipelines, ensuring smooth and efficient operation in a wide range of industrial applications.The Pump Rubber Flex Connector is made from high-quality rubber materials that are highly resistant to abrasion, corrosion, and extreme temperatures. This makes it ideal for use in demanding and harsh environments, where traditional metal connectors may be prone to failure or damage. With its flexible design, the Pump Rubber Flex Connector can accommodate for movement and vibration, helping to prolong the lifespan of both the pump and the pipeline.Flex Connector has a long-standing reputation for producing durable and reliable rubber products. With over 20 years of experience in the industry, the company has established itself as a trusted supplier to a wide range of industries including mining, construction, agriculture, and manufacturing. Their products are known for their superior performance, and the Pump Rubber Flex Connector is no exception.In addition to its durability, the Pump Rubber Flex Connector is also easy to install and maintain. Its flexible design allows for quick and simple installation, while its rugged construction reduces the need for frequent maintenance and replacement. This can help to minimize downtime and maintenance costs, ultimately leading to improved productivity and cost savings for industrial operators."We are thrilled to introduce our new Pump Rubber Flex Connector to the market," said the spokesperson for Flex Connector. "We have put a great deal of effort into developing this product to ensure that it meets the needs of our customers. We believe that its unique combination of durability, flexibility, and ease of use will make it a valuable addition to any industrial operation."The Pump Rubber Flex Connector is available in a range of sizes and configurations to suit different pump and pipeline systems. Custom options are also available to meet specific requirements, ensuring that customers can find the perfect solution for their application. Flex Connector is committed to providing personalized and responsive service to their customers, and they are equipped to assist with any technical questions or special requests.As part of their commitment to quality and reliability, Flex Connector conducts rigorous testing and quality control procedures on all of their products. The Pump Rubber Flex Connector is no exception, and it has been subjected to extensive testing to ensure that it meets the highest standards for performance and durability. This attention to detail is a hallmark of Flex Connector's approach to product development, and it has helped to solidify their reputation as a trusted supplier of industrial rubber products.With the launch of the Pump Rubber Flex Connector, Flex Connector continues to demonstrate their dedication to innovation and customer satisfaction. Their commitment to producing high-quality, reliable, and durable rubber products makes them a valuable partner for industrial operators seeking to optimize their operations. As the demand for flexible and reliable pump connections continues to grow, the Pump Rubber Flex Connector is poised to make a significant impact in the industry.

Essential Rubber Bellow Specifications for Various Applications

Title: Rubber Bellow Specification Garnering Attention in Diverse IndustriesIntroduction:In a rapidly evolving industrial landscape, the demand for high-quality rubber bellows is on the rise. Renowned for their versatility, durability, and ability to withstand extreme environmental conditions, rubber bellows are vital components in several industries, including automotive, aerospace, and manufacturing. Today, we focus on the specifications of these innovative products and their indispensable role in various sectors.Versatility in Design and Functionality:Rubber bellows are engineered to accommodate various applications, ensuring efficient and reliable performance. These flexible components are primarily used for sealing, protecting, and absorbing movements or vibrations in machinery and equipment. From sealing shafts and couplings in automotive power steering systems to being extensively used in HVAC systems for absorbing mechanical vibrations, rubber bellows offer exceptional adaptability across industries.Materials and Manufacturing Processes:While rubber bellows are available in a range of types and specifications, the most common materials used include natural rubber, synthetic rubber such as neoprene or EPDM, and silicone rubber. These materials are chosen based on the specific application requirements and desired characteristics such as chemical resistance, temperature resistance, or flexibility.The manufacturing processes of rubber bellows involve molding rubber into various shapes, with intricate designs and customizations to suit different applications. The use of advanced machinery, such as injection molding or extrusion, ensures high precision and consistency in production.Environmental and Performance Specifications:Rubber bellows are designed to withstand a wide range of environmental conditions, ensuring prolonged functionality even in demanding applications. They exhibit excellent resistance to heat, humidity, harsh chemicals, and oil, making them ideal for industries such as construction, automotive, and manufacturing.Furthermore, rubber bellows must perform reliably under mechanical stress, ensuring the safety and productivity of the equipment they are integrated into. They are tested for factors such as fatigue resistance, compression set, and tensile strength, ensuring optimum performance throughout their operational life.Applications in Various Industries:The automotive sector extensively relies on rubber bellows in critical components such as air induction systems, drive shafts, and suspension systems. Their ability to absorb vibrations and movements helps enhance overall driving experience while reducing wear and tear in crucial parts.In the aerospace industry, rubber bellows play a pivotal role in aircraft construction. These components are used in areas that demand precise sealing, such as wing flaps and landing gear systems. Due to their exceptional resistance to extreme temperatures and pressure differentials, rubber bellows contribute to the overall safety and reliability of aircraft operations.Moreover, in the manufacturing sector, rubber bellows are utilized in machinery such as pumps, compressors, and engines, where they provide effective sealing, absorb vibrations, and protect crucial moving parts. Their durability and resistance to environmental factors ensure extended service life and increased productivity.Conclusion:Rubber bellows, with their versatility, durability, and wide-ranging specifications, have become indispensable components across industries. From automotive to aerospace and manufacturing, these flexible connectors play a vital role in ensuring the efficient and reliable functionality of various equipment and machinery. With ongoing advancements in material science and manufacturing processes, the demand for rubber bellows is expected to grow further in the years to come, promoting enhanced safety and productivity in diverse industrial sectors.

Learn about the importance of expansion joints in piping systems

Expansion Joints Piping (EJP) is a critical component in various industries, helping to absorb vibrations, reduce movement, and allow for thermal expansion in pipelines and duct systems. With a commitment to quality and innovation, {} has been a pioneer in the development and production of expansion joints, providing reliable solutions for a wide range of applications.Established in [year], {} has dedicated over [number] years to the research, development, and manufacturing of expansion joints piping. The company has grown to become a leading supplier in the industry, serving customers across the globe with its high-quality products and exceptional customer service.One of the key factors that sets {} apart from competitors is its unwavering commitment to excellence. The company places a strong emphasis on quality control and continuously invests in advanced technology and equipment to ensure that its expansion joints meet the highest standards. With a team of experienced engineers and technicians, {} is able to design and manufacture custom expansion joints to meet the unique needs of its customers.In addition to its focus on quality, {} is also dedicated to innovation. The company is constantly exploring new materials and manufacturing techniques to improve the performance and longevity of its expansion joints. By staying at the forefront of technological advancements, {} is able to offer cutting-edge solutions that deliver reliable performance in even the most demanding environments.Furthermore, {} understands the importance of providing exceptional customer service. The company works closely with its clients to understand their specific requirements and to provide tailored solutions that meet their needs. With a global network of distributors and sales agents, {} is able to offer responsive support and timely delivery to customers around the world.The applications for expansion joints piping are diverse, spanning across industries such as oil and gas, power generation, chemical processing, and HVAC systems. In the oil and gas industry, for example, expansion joints are essential for accommodating the movement and thermal expansion of pipelines, helping to prevent stress and damage to the infrastructure. In power generation facilities, expansion joints play a critical role in absorbing vibrations and movements in duct systems, contributing to the overall efficiency and reliability of the operation.In the chemical processing industry, expansion joints are utilized to handle corrosive and high-temperature fluids, providing a flexible and durable solution for piping systems. In HVAC systems, expansion joints help to reduce noise and vibration, improving the comfort and performance of the building's mechanical infrastructure.With its extensive experience and expertise, {} is well-positioned to meet the needs of these industries and more. The company's comprehensive range of expansion joints and accessories caters to a diverse set of requirements, offering solutions for high-temperature, high-pressure, corrosive, and other challenging operating conditions.As a trusted partner for expansion joints piping, {} is committed to providing reliable products, innovative solutions, and exceptional customer service to its clients. With a proven track record of success and a dedication to continuous improvement, {} is poised to remain at the forefront of the industry for years to come.

What is a Flexible Compensator and How Does it Work?

Flexible Compensator Innovations: Revolutionizing the IndustryIn today's fast-paced and constantly evolving industrial landscape, companies are continuously seeking innovative solutions to improve efficiency and productivity. One company that is leading the way in this regard is [Company Name], a renowned industry leader in the development and manufacturing of cutting-edge flexible compensators. These specialized products have garnered widespread acclaim for their ability to address a wide range of challenges faced by industries such as oil and gas, petrochemical, and power generation.[Company Name], headquartered in [Location], has been at the forefront of flexible compensator innovation for over three decades. The company's commitment to research and development has resulted in the creation of a diverse portfolio of advanced compensator solutions that have set new benchmarks for performance and reliability. Its team of skilled engineers and technicians work tirelessly to ensure that every product meets the highest industry standards and is tailored to the specific needs of its customers.The key to the success of [Company Name]'s flexible compensators lies in their unique design and construction. These components are expertly engineered to absorb and compensate for movements, vibrations, and misalignments in piping systems, thereby reducing stress on equipment and extending their operational life. The company's comprehensive range of flexible compensators includes metal bellows, fabric expansion joints, and rubber expansion joints, each offering distinct advantages for different applications.In addition to their functional benefits, [Company Name]'s flexible compensators are known for their exceptional durability and resistance to corrosion, ensuring that they can withstand the harshest operating conditions. Furthermore, the company's commitment to sustainability is evident in the materials and manufacturing processes used for its products, which are designed to minimize environmental impact while maintaining superior performance.[Company Name] places great emphasis on providing its customers with comprehensive support and expertise to ensure the successful implementation of its flexible compensator solutions. The company's team of technical specialists is readily available to offer guidance on product selection, customization, and installation, as well as to provide ongoing maintenance and support services. This commitment to customer satisfaction has earned [Company Name] a sterling reputation as a trusted partner for businesses in need of reliable compensator solutions.One of the most recent developments from [Company Name] that has generated considerable excitement in the industry is its latest innovation in flexible compensator technology. This breakthrough has resulted in a new generation of products that offer enhanced flexibility, operational efficiency, and longevity. By leveraging advanced materials and manufacturing techniques, [Company Name] has once again raised the bar for what can be achieved in the field of compensator technology.The impact of [Company Name]'s flexible compensator innovations has been felt across a wide spectrum of industries. In the oil and gas sector, these cutting-edge products have played a crucial role in ensuring the integrity and safety of piping systems in challenging offshore and onshore environments. Similarly, in the petrochemical industry, [Company Name]'s compensators have proven indispensable for addressing the complex thermal and chemical dynamics encountered in processing facilities. Moreover, in power generation plants, where reliability is paramount, the use of [Company Name]'s flexible compensators has contributed to optimizing performance and minimizing downtime.Looking ahead, [Company Name] remains firmly committed to driving further advancements in flexible compensator technology. As industries continue to evolve and face new challenges, the company's relentless pursuit of innovation will undoubtedly result in the development of even more advanced and versatile compensator solutions.In conclusion, [Company Name]'s pioneering work in the field of flexible compensators has had a transformative effect on numerous industries, bringing about significant improvements in safety, productivity, and operational reliability. Through a combination of cutting-edge engineering, superior materials, and unwavering dedication to customer satisfaction, [Company Name] has firmly established itself as a global leader in this specialized field. As it continues to push the boundaries of what is possible, the company's innovations are set to shape the future of industrial compensator technology for years to come.

Essential Guide to Properly Installing Pipe Joints

{Company Introduction} is proud to announce their latest innovation in pipe joint technology. The new {Pipe Joint} is a game-changer in the industry, offering improved performance and durability for a wide range of applications.The {Pipe Joint} is designed to provide a secure and reliable connection between pipes, ensuring minimal risk of leaks or failures. Built with high-quality materials and precision engineering, this new pipe joint is set to redefine standards in the industry.One of the key features of the {Pipe Joint} is its advanced sealing technology, which enhances the joint's resistance to pressure, temperature, and corrosion. This makes it suitable for use in a variety of environments, from industrial settings to domestic applications.In addition to its exceptional performance, the {Pipe Joint} is also designed for easy installation, saving time and labor costs for the end user. Its user-friendly design and compatibility with different pipe materials make it a versatile and efficient solution for various piping systems."We are excited to introduce the {Pipe Joint} to the market," said the spokesperson for {Company Introduction}. "Our team has worked tirelessly to develop a product that not only meets but exceeds the expectations of our customers. We believe that this innovative pipe joint will set new benchmarks for reliability and performance in the industry."The {Pipe Joint} is also designed with sustainability in mind, with its durable construction and long service life contributing to reduced maintenance and replacement needs. This makes it an environmentally conscious choice for businesses and individuals looking to minimize their impact on the planet.To ensure the quality and reliability of the {Pipe Joint}, {Company Introduction} has subjected it to rigorous testing and certification processes. As a result, customers can have full confidence in the performance and durability of this new product.The launch of the {Pipe Joint} represents {Company Introduction}'s ongoing commitment to innovation and excellence in the pipe joint industry. With a track record of delivering cutting-edge solutions to the market, the company continues to lead the way in providing reliable and efficient piping products.Customers and industry professionals alike can look forward to experiencing the superior performance and benefits of the {Pipe Joint}. Its availability in the market will empower them to achieve greater efficiency and peace of mind in their piping systems.In conclusion, the introduction of the {Pipe Joint} by {Company Introduction} marks a significant milestone in the evolution of pipe joint technology. With its advanced features, robust construction, and sustainable design, this innovative product is set to raise the bar for performance and reliability in the industry, setting a new standard for pipe joints.

Flexible Pipe Fittings: An Essential Guide

Title: Game-Changing Flexible Pipe Fittings Revolutionize the Plumbing IndustryIntroduction:In a groundbreaking move, a leading manufacturer, whose name cannot be disclosed due to brand restrictions, has unveiled a highly innovative line of flexible pipe fittings. These game-changing fittings are poised to revolutionize the plumbing industry, offering unmatched durability, versatility, and ease of installation. With the ability to adapt to various pipe materials, angles, and sizes, these cutting-edge fittings are set to transform the way we approach plumbing systems.Flexible Pipe Fittings: A Marvel of EngineeringThe newly introduced flexible pipe fittings are the result of meticulous engineering and technological advancements. By combining state-of-the-art materials and design principles, the manufacturer has successfully created a fitting that ensures optimal performance and longevity. These fittings offer versatile connectivity options, making them compatible with a wide range of pipe materials like PVC, copper, and PEX, eliminating the need for multiple adapters and reducing overall costs.Unmatched Durability and Resistance:One of the most significant advantages of these flexible fittings is their exceptional durability and resistance to wear and tear. Constructed from high-quality materials, they can withstand extreme temperatures, corrosive substances, and pressure variations. Additionally, the fittings are engineered to reduce the risk of leaks, providing long-term reliability and peace of mind to plumbers and homeowners alike.Versatility and Ease of Installation:Thanks to their flexibility, these fittings can adapt to various pipe sizes and angles, simplifying installation processes and making them suitable for a wide range of applications. Whether it's a complex plumbing system or a simple household repair, these versatile fittings ensure secure connections with minimal effort. Plumbers will appreciate the time-saving benefits of these fittings, enabling them to complete projects efficiently and meet deadlines.Environmental Considerations:Understanding the importance of sustainable solutions in today's world, the manufacturer has prioritized eco-friendly practices during production. These flexible pipe fittings are made from recyclable materials and engineered with a focus on minimizing both material waste and energy consumption. This commitment to environmental consciousness can benefit the plumbing industry by reducing its carbon footprint and promoting a greener future.Positive Impacts on the Plumbing Industry:The entry of these groundbreaking flexible pipe fittings into the plumbing industry is expected to have transformative effects. Their adaptability will significantly simplify plumbing installations, reducing overall costs and ensuring efficient system operations. The durability and resistance of these fittings will result in fewer leaks and repairs, enhancing the longevity of plumbing systems and improving the overall quality of plumbing services.Market Response and Future Prospects:The unveiling of these game-changing fittings has already generated considerable excitement within the industry. Plumbing professionals and experts anticipate a surge in demand for this innovative technology due to its numerous advantages. Furthermore, the flexibility and compatibility of these fittings with existing plumbing infrastructures mean that they can be seamlessly incorporated into both new construction projects and renovation works, widening their market potential.Conclusion:The introduction of these groundbreaking flexible pipe fittings is set to revolutionize the plumbing industry. With unmatched durability, versatility, and ease of installation, they offer a future-proof solution that will streamline plumbing operations and improve system performance. This advancement not only benefits plumbers and homeowners but also contributes to a more sustainable and environmentally conscious industry. As the demand for these fittings continues to grow, the manufacturer aims to further enhance their product line, driving innovation and progress within the plumbing sector.

Discover the Benefits of Metal Bellows Packless Expansion Joints

Metal Bellows Packless Expansion Joints – The Future of Piping SystemsThe use of pipes in various industries like manufacturing, aerospace, and oil and gas requires certain devices that can help in accommodating the expansion and contraction of the pipes due to temperature changes. One such device that is gaining popularity in the market is the Metal Bellows Packless Expansion Joint.Metal Bellows Packless Expansion Joints are flexible pipe connectors that help in reducing the stresses caused by the thermal expansion and contraction of pipes. They are designed to accommodate axial, lateral, and angular movement of pipes without changing the direction of the flow, making them a perfect solution for piping systems that require a high degree of flexibility and durability.The Metal Bellows Packless Expansion Joints are made of high-quality metal alloy bellows that can withstand high temperatures and pressure fluctuations. These joints are specially designed to provide a leak-proof seal, eliminating the risk of fluid leakage and ensuring the safety of the overall piping system.One of the key advantages of Metal Bellows Packless Expansion Joints is their long service life. These expansion joints are highly durable and resistant to wear and tear, ensuring that they provide a reliable solution for the long term.Another benefit of Metal Bellows Packless Expansion Joints is their ease of installation. They come in various sizes and configurations to fit different types of piping systems. This makes them easy to install and maintain, reducing the overall downtime of the system.At {company name}, we are committed to providing our customers with the best quality Metal Bellows Packless Expansion Joints. Our expansion joints are manufactured using state-of-the-art technology, ensuring that they meet the highest industry standards.Our team of experts works closely with our clients to understand their specific requirements and provide customized solutions. We offer a wide range of Metal Bellows Packless Expansion Joints in different sizes and configurations to meet the unique needs of our clients.In addition to our high-quality products, we also provide exceptional customer service to our clients. Our team of experts is available round the clock to provide support and assist our clients in any way possible.Overall, Metal Bellows Packless Expansion Joints are a reliable solution for piping systems that require flexibility and durability. With their long service life and ease of installation, these expansion joints are the future of the piping industry. If you are looking for high-quality Metal Bellows Packless Expansion Joints, {company name} is your one-stop solution!