- Home

- News

- Introducing a Revolutionary Threaded Union Rubber Expansion Joint: The Ultimate Solution for Enhanced Flexibility and Durability

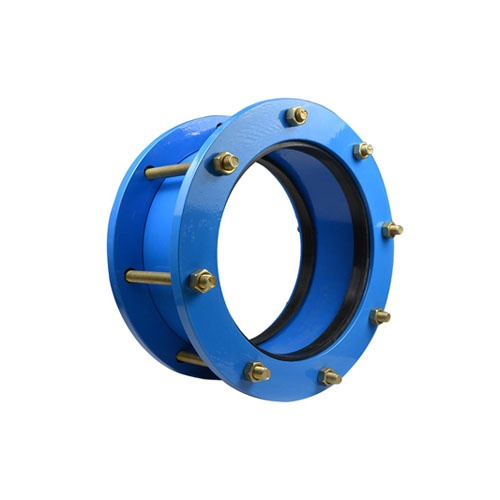

Introducing a Revolutionary Threaded Union Rubber Expansion Joint: The Ultimate Solution for Enhanced Flexibility and Durability

By:Admin

Introduction:

In recent years, the demand for high-quality and efficient solutions in industrial piping systems has been increasing rapidly. To meet these demands, a leading company in the field of fluid transfer technology has introduced an innovative product – the Threaded Union Rubber Expansion Joint. This groundbreaking solution is set to revolutionize the industry, providing enhanced versatility, durability, and operational efficiency.

1. Introduction to the Threaded Union Rubber Expansion Joint:

The Threaded Union Rubber Expansion Joint is a highly engineered product designed to cater to the challenging requirements of modern industrial piping systems. It is manufactured using state-of-the-art technology and high-quality materials, ensuring its exceptional performance and longevity.

2. Versatility in Applications:

This versatile expansion joint finds applications in a wide range of industries, including chemical processing, petrochemicals, water treatment, power generation, and heating, ventilation, and air conditioning (HVAC) systems. Its adaptability to different piping configurations makes it an ideal choice for various projects.

3. Benefits and Features:

The Threaded Union Rubber Expansion Joint offers several significant benefits:

a. Reduced Pipe Stress and Noise:

The expansion joint absorbs vibrations, pipe movements, and thermal expansions, significantly reducing stress on connected equipment and minimizing noise levels. This enhances the overall operational efficiency and extends the lifespan of the entire piping system.

b. Enhanced Flexibility:

Designed with flexibility in mind, the expansion joint compensates for axial, lateral, and angular movements, ensuring optimal system performance even in challenging conditions.

c. Superior Endurance:

The high-quality rubber material used in the construction of this expansion joint enables it to withstand aggressive chemicals, extreme temperatures, and demanding operating conditions, guaranteeing long-term reliability.

d. Easy Installation and Maintenance:

With its user-friendly design and threaded union connection system, installation and maintenance processes are streamlined, minimizing downtime and resource requirements.

e. Customizable Options:

The Threaded Union Rubber Expansion Joint can be customized to meet specific requirements, including variations in size, pressure ratings, materials, and end connections, maximizing its suitability for a wide range of projects.

4. Reducing Environmental Impact:

The company is committed to sustainability and environmental responsibility. The Threaded Union Rubber Expansion Joint is designed to minimize leaks and prevent fugitive emissions, reducing the ecological impact of industrial processes and ensuring compliance with strict environmental regulations.

5. Quality Assurance:

The company adheres to stringent quality control measures and manufacturing standards, ensuring that each expansion joint meets the highest levels of performance, reliability, and safety. Stringent testing protocols are implemented throughout the manufacturing process to guarantee product excellence.

6. Conclusion:

The introduction of the Threaded Union Rubber Expansion Joint represents a significant advancement in industrial fluid transfer technology. Its innovative features, versatility, and durability make it a trusted choice for engineers and project managers seeking optimized performance and efficiency in a wide range of industrial applications. By prioritizing customer satisfaction, environmental responsibility, and quality assurance, the company sets new industry standards, cementing its position as an industry leader.

In conclusion, the Threaded Union Rubber Expansion Joint is setting a new benchmark in the industrial piping systems market, providing a high-quality, versatile, and durable solution that meets the evolving demands of various industries.

Company News & Blog

Experts Reveal the Key Benefits of Expansion Joints for Enhanced Structural Integrity

Expansion Joint Solutions Company Announces Four New ProductsExpansion Joint Solutions, a leader in the industrial expansion joint market, recently announced the release of four new products. The company specializes in providing high-quality, cost-effective solutions for a variety of industries including petrochemicals, power generation, paper, wastewater treatment, and more.The four new products include:1. The Sliding Flange Expansion JointThis type of expansion joint is designed for pipelines where lateral movements occur. The sliding flange allows the joint to move in two directions, accommodating thermal expansion and contraction without putting stress on the pipe. The joint can be customized to meet specific requirements and can be made from various materials, including rubber and metal.2. The Tied Universal Expansion JointThis expansion joint is designed to accommodate axial, lateral, and angular movements. The tied universal joint is especially useful in high-pressure and high-temperature environments, making it ideal for applications in the petrochemical and power generation industries.3. The Filler Ring Expansion JointThis type of expansion joint is designed for applications that require a high level of chemical compatibility. The filler ring is made from high-performance materials such as PTFE, which is resistant to corrosion and can withstand extreme temperatures. The filler ring joint is ideal for use in the chemical, pharmaceutical, and food and beverage industries.4. The Hinged Expansion JointThe hinged expansion joint is designed to accommodate angular movements and is particularly useful in applications where piping systems must be connected at an angle, such as in air-handling systems. The hinge mechanism allows for easy installation and maintenance, and can be designed to meet specific requirements.Expansion Joint Solutions is excited to offer these new products to its customers. The company is committed to providing high-quality, cost-effective solutions to meet the needs of its clients.“Our goal is to provide innovative solutions for our clients, and these new products are an example of that commitment,” said a spokesperson for the company. “We recognize that every application is unique, and we work closely with our customers to design custom solutions that meet their specific needs.”Expansion Joint Solutions has over 30 years of experience in the industry, and its expert staff has the knowledge and skill to design and manufacture customized solutions for any application. The company’s commitment to quality and customer service has made it a leader in the expansion joint market.“We are dedicated to providing superior products and services to our customers,” said the spokesperson. “We pride ourselves on our ability to listen to our customers’ needs and provide solutions that exceed their expectations.”Expansion Joint Solutions is a global company with facilities in North America, Europe, the Middle East, and Asia. Its products are used by a wide range of industries, including petrochemicals, power generation, paper, wastewater treatment, and more.For more information about Expansion Joint Solutions and its new products, visit the company’s website at www.expansionjointsolutions.com.

Stainless Steel Braided Flexible Tap Connector for High-Pressure Applications

Flexible Tap Connectors: The Ideal Way to Connect Taps and AppliancesOne of the key components in any plumbing system is the tap connector. Tap connectors are used to join pipework to appliances or taps and come in a variety of materials and designs. One of the most popular types of tap connectors is the flexible tap connector, which offers numerous benefits and advantages over traditional rigid pipework connections.In this blog post, we will take a closer look at flexible tap connectors, their features, and the reasons why they are the ideal way to connect taps and appliances in any plumbing system.What Is a Flexible Tap Connector?A flexible tap connector is a type of flexible hose that is designed to connect taps and other appliances to the water supply. It is made up of a stainless steel over braided EPDM rubber tube that is reinforced with a flexible steel mesh. This design provides excellent flexibility, durability, and strength, making it ideal for use in a variety of plumbing applications.Flexible tap connectors are available in a range of sizes and lengths to suit different plumbing systems. They typically come with one compression end and a swivel nut with a washer on the other end, which allows for easy and quick installation.Features of Flexible Tap ConnectorsStainless Steel Over Braided EPDM Rubber Tube: The main feature of a flexible tap connector is the stainless steel over braided EPDM rubber tube. This material is highly durable and resistant to corrosion, making it ideal for use in wet and humid environments.Nickel Plated Brass Fittings: The fittings that come with flexible tap connectors are made from nickel plated brass. This gives them excellent strength and durability, as well as protection against corrosion.15 Bar Max Working Pressure: Flexible tap connectors are designed to withstand high pressure and are rated at a maximum working pressure of 15 bar. This makes them suitable for use in a variety of plumbing systems.One Compression End & Swivel Nut: Flexible tap connectors come with a compression end and a swivel nut at the other end. This allows for easy installation and makes it easy to connect taps and appliances to the plumbing system.70C Max Temp: Flexible tap connectors are designed to operate in temperatures of up to 70C, making them suitable for use in hot water systems.Advantages of Flexible Tap ConnectorsEasy to Install: Flexible tap connectors are incredibly easy to install. They are designed to be flexible, which means they can be easily bent and manoeuvred into place, making installation quick and straightforward.Reduced Leak Risk: Traditional rigid pipework connections can often be prone to leaks. However, flexible tap connectors are designed to reduce the risk of leaks, thanks to their strong and durable construction.Flexible Design: The flexible design of flexible tap connectors means they can be easily and quickly adjusted to fit the requirements of different plumbing systems. This makes them a versatile solution that can be used in a wide variety of applications.Reduced Noise: The flexible design of flexible tap connectors can also help to reduce noise in the plumbing system. This makes them ideal for use in residential and commercial buildings, where noise can be an issue.Improved Aesthetics: Flexible tap connectors are also available in a range of colours and styles, which means they can be matched to the design and colour scheme of different plumbing systems. This can help to improve the overall aesthetics of the system.ConclusionFlexible tap connectors are an essential component in any plumbing system. They provide numerous benefits, including flexibility, durability, and ease of installation. They are also available in a variety of sizes, lengths, and styles, making them suitable for use in a wide range of applications. If you are looking to improve your plumbing system's performance, then flexible tap connectors are the ideal solution. So, why not invest in flexible pump connectors today?

Rubber Bellows and Convoluted Boots: Versatile Seals for Various Industrial Applications

and Convolute Rubber Boots.NBR Rubber Bellows and Convolute Rubber Boots: The Essential Sealing Solution for Various ApplicationsRubber bellows and convolute rubber boots are flexible seals designed to prevent the entry of dust, water, and other environmental elements in a variety of applications. These essential sealing solutions are used extensively in industries such as automotive, military, aerospace, and marine. The use of high-quality NBR rubber bellows and convolute rubber boots ensures that your equipment and products are protected from wear and tear, dust, and other harmful contaminants.NBR (Nitrile Butadiene Rubber) is a synthetic rubber material that is known for its excellent resistance to oil, water, and chemicals. This makes it an ideal material for manufacturing rubber bellows and convolute boots that require protection from environmental elements. NBR rubber bellows and convolute rubber boots also have excellent heat resistance and can withstand harsh conditions, making them suitable for use in high-temperature applications.In the automotive industry, NBR rubber bellows and convolute rubber boots are used extensively in suspension systems, steering systems, and drivetrain components. These seals provide protection against dirt, dust, and other contaminants, which can cause wear and tear on vehicle components. The use of NBR rubber bellows and convolute rubber boots ensures that vehicle systems remain protected, ensuring efficient operation and increased lifespan.In the marine industry, NBR rubber bellows and convolute rubber boots are used in a variety of applications such as boat engines, outboard motors, and marine pumps. These seals protect the equipment from saltwater, sand, and other harmful elements that can cause corrosion and damage. The use of NBR rubber bellows and convolute rubber boots ensures that marine equipment remains protected and operates efficiently, even in harsh marine conditions.In the military and aerospace industry, NBR rubber bellows and convolute rubber boots are used in a variety of applications such as sealing components in aircraft and missiles. These seals protect critical components from dust, water, and other environmental elements that can cause equipment failure. The use of NBR rubber bellows and convolute rubber boots ensures that sensitive military and aerospace equipment remains operational and protected, even in extreme conditions.In conclusion, NBR rubber bellows and convolute rubber boots are essential sealing solutions that provide protection against environmental elements in various industrial applications. Their excellent resistance to oil, water, and chemicals ensures they are suitable for use in harsh environments, making them a reliable choice for sealing applications. Additionally, the use of high-quality NBR rubber bellows and convolute rubber boots improves equipment and product lifespan, ensuring efficient and long-lasting operation. If you need sealing solutions for environmental protection, consider using NBR rubber bellows and convolute rubber boots, and enjoy the benefits of effective protection against environmental elements.

Effective Sealing Systems for Pipe-to-Manhole and Pipe-to-Pipe Connections

Title: Innovative Connector Sealing Systems Revolutionize Pipe-to-Manhole and Pipe-to-Pipe ConnectionsIntroduction:The growth of urban infrastructure and the need for efficient wastewater management have led to an increased demand for reliable and durable pipe connectors. Recognizing this, Rubber Pipe Connectors has introduced pioneer connector sealing systems that aim to revolutionize pipe-to-manhole and pipe-to-pipe connections. These innovative solutions ensure seamless integration, improve performance, and enhance the overall efficiency of wastewater management systems.Connector Sealing Systems:1. Pipe-to-Manhole Connector Sealing Systems:Rubber Pipe Connectors has developed a cutting-edge range of connector sealing systems designed specifically for pipe-to-manhole connections. These connectors provide an air and watertight seal, preventing leakage and minimizing the risk of contamination. By eliminating the possibility of seepage, these sealing systems contribute to a healthier environment and a safer infrastructure.Utilizing the latest materials and manufacturing techniques, these connectors ensure easy installation, enhanced durability, and reduced maintenance requirements. The precisely engineered design of the connectors ensures a secure and long-lasting connection, even under demanding conditions.2. Pipe-to-Pipe Connector Sealing Systems:In addition to pipe-to-manhole connections, Rubber Pipe Connectors offers an exceptional range of connector sealing systems for pipe-to-pipe connections. These connectors facilitate the efficient flow of wastewater between different pipe sections and ensure a reliable and leak-free transition.Rubber Pipe Connectors' pipe-to-pipe sealing systems are tailored to accommodate various pipe sizes and materials commonly used in wastewater management. Their flexibility allows for easy installation and adaptability, minimizing the need for costly alterations or replacements. These connectors simplify the maintenance process and contribute to the longevity of the entire piping system.Advantages of Rubber Pipe Connectors' Sealing Systems:1. Enhanced Performance: Rubber Pipe Connectors' sealing systems ensure a secure and reliable connection that mitigates the risk of leaks, seepage, and potential contamination. By maintaining the integrity of the system, these connectors contribute to a more efficient wastewater management process.2. Durability: The cutting-edge materials and manufacturing techniques employed by Rubber Pipe Connectors guarantee the longevity and durability of their sealing systems. Withstanding the test of time and demanding operational conditions, these connectors reduce the need for frequent replacements or maintenance.3. Easy Installation and Adaptability: Rubber Pipe Connectors' sealing systems are designed with easy installation in mind, significantly reducing downtime during system installation or repairs. Their adaptability to various pipe sizes and materials simplifies the connection process, streamlining the overall operation.4. Cost-Effectiveness: By providing reliable and leak-free connections, Rubber Pipe Connectors' sealing systems minimize the occurrence of costly repairs and potential damage caused by leakage. The durability and low maintenance requirements of these connectors further contribute to their cost-effectiveness.Conclusion:The introduction of Rubber Pipe Connectors' innovative sealing systems for pipe-to-manhole and pipe-to-pipe connections marks a significant breakthrough in the field of wastewater management. These cutting-edge solutions offer enhanced performance, durability, easy installation, and cost-effectiveness. As urban areas continue to expand, the demand for reliable, leak-free, and sustainable connector sealing systems will only grow. Rubber Pipe Connectors' state-of-the-art products bring us one step closer to achieving efficient, robust, and environmentally friendly infrastructures.

: What You Need to Know When it comes to industrial equipment, especially pipelines and piping systems, expansion joints are a key component for efficiency, safety, and longevity. Expansion joints are designed to provide flexibility and accommodate for any movement, vibration, or thermal expansion that may occur within a piping system, while ensuring that it remains closed and leak-free. Additionally, expansion joints also help reduce stress on piping equipment that arises from temperature changes and mechanical forces that may cause equipment to suffer permanent deformation or failure. Among the most commonly used materials for expansion joint manufacturing is neoprene, which has demonstrated time and again as an ideal choice for applications where resisting heat, chemicals and ozone is vital. In this article, we'll delve deeper into the world of neoprene expansion joints and explain why they are so important for pipeline applications.What is Neoprene? Neoprene is a synthetic rubber that features a highly textured surface and an excellent resistance to the detrimental effects of oil, heat, and various chemical agents. Moreover, neoprene can withstand ozone attacks, sunlight, and weathering, making it a prime choice for expansion joint construction. This versatile material offers a dynamic range of properties such as excellent compression set, low water absorption, a broad temperature range, and good resilience. And because of its ability to withstand harsh conditions, neoprene is often used in applications requiring high-speed and high-pressure operations. Why Choose a Neoprene Expansion Joint? Neoprene Expansion joints have become the go-to choice for many industrial applications for several reasons: 1. Resistant to weathering and ozone Neoprene is resistant to the harmful effects of the sun, weathering and ozone, which makes it perfect for use in outdoor applications. Over time, prolonged exposure to ozone and UV rays can cause degradation to the rubber products present in many industrial applications, ultimately causing breakdowns in the equipment. Hence, by choosing neoprene expansion joints, you're ensuring longevity and cost-effective operation over the long haul.2. Impressive heat resistanceNeoprene Expansion joints are capable of withstanding temperatures ranging between -60 °C and 120°C. Neoprene exceeds the physical and mechanical properties of many other elastomers and is an excellent option for piping systems in high-temperature environments, such as production plants, power generation systems, and chemical processing facilities.3. Corrosion resistantNeoprene Expansion Joints resist most corrosive chemicals, including industrial solvents, acids, and hydrocarbons. Equipment and pipes that transport hazardous or corrosive substances need to be carefully protected to avoid accidents, which makes neoprene expansion joints a popular choice for many pipeline applications.4. VersatileSince its development in the 1930s, neoprene has been used in various industrial applications ranging from automotive to aerospace. Like all synthetic rubbers, neoprene can be tailored to meet the specific needs of different industries. It is a highly versatile chemical compound that can be configured to suit different situations.Final Thoughts Neoprene Expansion Joints offer numerous benefits that improve the efficiency, safety, and longevity of your piping systems. Whether you are working in a plant that transports hazardous substances, demanding high-temperature environments, or has to endure the harsh effects of weathering, neoprene expansion joints are a material that you can count on to keep your operations running smoothly. In essence, neoprene expansion joints can offer significant cost savings in the long run by reducing equipment downtime and other related costs. In conclusion, you can rely on neoprene as the perfect material for your expansion joint needs, and we at {insert your company name} are here to help you make the best possible choice when it comes to materials. We offer the best neoprene expansion joints with the finest quality, quantity, and price to fit your specific needs. Contact us today to learn more about our services and how we can help you!

Introducing a Revolutionary Threaded Union Rubber Expansion Joint: The Ultimate Solution for Enhanced Flexibility and Durability

Title: Innovative Threaded Union Rubber Expansion Joint Revolutionizing Industrial Piping SystemsIntroduction:In recent years, the demand for high-quality and efficient solutions in industrial piping systems has been increasing rapidly. To meet these demands, a leading company in the field of fluid transfer technology has introduced an innovative product – the Threaded Union Rubber Expansion Joint. This groundbreaking solution is set to revolutionize the industry, providing enhanced versatility, durability, and operational efficiency.1. Introduction to the Threaded Union Rubber Expansion Joint:The Threaded Union Rubber Expansion Joint is a highly engineered product designed to cater to the challenging requirements of modern industrial piping systems. It is manufactured using state-of-the-art technology and high-quality materials, ensuring its exceptional performance and longevity.2. Versatility in Applications:This versatile expansion joint finds applications in a wide range of industries, including chemical processing, petrochemicals, water treatment, power generation, and heating, ventilation, and air conditioning (HVAC) systems. Its adaptability to different piping configurations makes it an ideal choice for various projects.3. Benefits and Features:The Threaded Union Rubber Expansion Joint offers several significant benefits:a. Reduced Pipe Stress and Noise:The expansion joint absorbs vibrations, pipe movements, and thermal expansions, significantly reducing stress on connected equipment and minimizing noise levels. This enhances the overall operational efficiency and extends the lifespan of the entire piping system.b. Enhanced Flexibility:Designed with flexibility in mind, the expansion joint compensates for axial, lateral, and angular movements, ensuring optimal system performance even in challenging conditions.c. Superior Endurance:The high-quality rubber material used in the construction of this expansion joint enables it to withstand aggressive chemicals, extreme temperatures, and demanding operating conditions, guaranteeing long-term reliability.d. Easy Installation and Maintenance:With its user-friendly design and threaded union connection system, installation and maintenance processes are streamlined, minimizing downtime and resource requirements.e. Customizable Options:The Threaded Union Rubber Expansion Joint can be customized to meet specific requirements, including variations in size, pressure ratings, materials, and end connections, maximizing its suitability for a wide range of projects.4. Reducing Environmental Impact:The company is committed to sustainability and environmental responsibility. The Threaded Union Rubber Expansion Joint is designed to minimize leaks and prevent fugitive emissions, reducing the ecological impact of industrial processes and ensuring compliance with strict environmental regulations.5. Quality Assurance:The company adheres to stringent quality control measures and manufacturing standards, ensuring that each expansion joint meets the highest levels of performance, reliability, and safety. Stringent testing protocols are implemented throughout the manufacturing process to guarantee product excellence.6. Conclusion:The introduction of the Threaded Union Rubber Expansion Joint represents a significant advancement in industrial fluid transfer technology. Its innovative features, versatility, and durability make it a trusted choice for engineers and project managers seeking optimized performance and efficiency in a wide range of industrial applications. By prioritizing customer satisfaction, environmental responsibility, and quality assurance, the company sets new industry standards, cementing its position as an industry leader.In conclusion, the Threaded Union Rubber Expansion Joint is setting a new benchmark in the industrial piping systems market, providing a high-quality, versatile, and durable solution that meets the evolving demands of various industries.

Revolutionary New Joint Technology Provides Unmatched Flexibility

Flexible Joint Revolutionizes the Industry with Innovative Engineering SolutionsIn today's rapidly evolving industrial landscape, improving the efficiency and performance of machinery and equipment has become paramount. As the demand for high-quality engineering solutions continues to rise, companies are constantly pushing boundaries to provide innovative products that enhance productivity in various industries. One such company that has been at the forefront of this revolution is an industry leader in providing cutting-edge flexible joint solutions (). With a keen focus on engineering excellence, they have revolutionized the industry by delivering state-of-the-art products that are designed to meet the evolving needs of their customers.Headquartered in (**City, Country**), the company has earned an enviable reputation for its commitment to innovation, reliability, and superior customer service. With a team of highly skilled engineers and technicians, they collaborate closely with clients to understand their unique requirements and tailor solutions to address specific challenges. Their relentless pursuit of technological advancements has set them apart from the competition, as they constantly strive to provide cutting-edge flexible joint solutions that exceed customer expectations.One of the company's flagship products is the innovative flexible joint, which has proven to be a game-changer in the industry. This versatile component plays a pivotal role in numerous applications, ranging from construction and manufacturing to aerospace and automotive sectors. The flexible joint effectively compensates for misalignments, vibrations, and thermal expansions, thereby minimizing stress on machinery and prolonging their lifespan. By allowing freedom of movement and absorbing shocks and loads, the flexible joint significantly enhances the overall performance and reliability of various types of equipment.What sets this flexible joint apart from traditional alternatives is its superior design and construction. Using advanced materials and state-of-the-art manufacturing processes, this flexible joint is not only highly durable but also offers exceptional resistance to corrosion and extreme temperatures. Its innovative design allows for easy installation and reduces maintenance time and costs. Additionally, with its smooth and silent operation, the flexible joint ensures a safe and comfortable working environment. These features make it an ideal choice for industries where precise alignment, smooth movement, and minimal downtime are crucial.The flexible joint has rapidly gained popularity among industrial giants, who have reported significant improvements in their operational efficiency and reduced maintenance costs after integrating these solutions into their machinery. The companies using the flexible joint have experienced reduced downtime, ensuring increased productivity and profitability. Its ability to reduce stress on machinery and dampen vibrations has resulted in improved equipment reliability, prolonging the lifespan of critical components. With its proven track record, the flexible joint has become an indispensable part of industrial machinery across a wide range of sectors.In addition to their world-class products, the company is dedicated to providing exceptional customer service. Their team of experts works closely with clients to understand their unique needs and challenges, offering customized solutions that meet specific requirements. The company's commitment to excellence goes beyond the sale of their products, as their technical support and after-sales service ensure clients receive ongoing assistance throughout the product lifecycle.Looking ahead, this industry leader continues to push the boundaries of engineering solutions. With ongoing investments in research, development, and technology, they aim to further enhance their product line and offer groundbreaking solutions to address emerging demands in the market. By combining customer feedback, market insights, and unparalleled engineering expertise, they are well-positioned to maintain their leadership in providing flexible joint solutions that drive industrial efficiency and productivity.In conclusion, the company has cemented its position as an industry leader by providing innovative flexible joint solutions. Their commitment to engineering excellence, customer satisfaction, and continuous improvement has revolutionized the industry, setting new standards for operational efficiency and reliability. With their game-changing products and exceptional customer service, this company is poised to remain at the forefront of the engineering solutions market, fueling progress and innovation for years to come.

Rubber Bellows Expansion Joint for Pipe System: A Comprehensive Guide

Pipe Rubber Bellows Expansion Joint(Company Introduction)[Company Name] is a leading manufacturer and supplier of Pipe Rubber Bellows Expansion Joints. With an established presence in the industry for over two decades, we have earned a reputation for delivering high-quality products to our esteemed clients. Our commitment to excellence and customer satisfaction has made us a preferred choice for various industries, including petrochemical, power generation, water treatment, and HVAC.With state-of-the-art manufacturing facilities and a dedicated team of skilled professionals, we have always strived to meet the ever-increasing demands of the market. Our production process adheres to strict quality control measures to ensure that our expansion joints meet international standards and specifications. Our aim is to provide durable, reliable, and efficient solutions that effectively address the challenges faced by our customers.[Company Name] understands the importance of innovation in a rapidly evolving industry. We continuously invest in research and development to develop cutting-edge technologies and advanced materials. Our team of engineers works closely with clients to understand their specific requirements and devise tailor-made solutions, ensuring that every product we deliver is engineered to perfection.Pipe Rubber Bellows Expansion Joints are a crucial component in piping systems as they compensate for thermal expansion, vibration, and misalignment. These joints are designed to absorb movements and stresses produced by thermal changes, thus protecting the integrity of the entire piping system. At [Company Name], we offer a wide range of expansion joints to suit various applications.Our Pipe Rubber Bellows Expansion Joints are meticulously crafted using premium-grade rubber materials that offer superior durability and resistance to chemical attacks, UV radiation, and extreme temperatures. The rubber bellows are reinforced with high-quality fabric to enhance their strength and flexibility. Additionally, they undergo rigorous testing to ensure they can withstand intense pressure, bending, and torsional forces.One notable feature of our expansion joints is their ability to absorb noise and vibrations, which aids in maintaining the overall stability and longevity of the piping system. Moreover, our expansion joints have low spring rates, allowing them to accommodate large axial movements while exerting minimal pressure on adjacent equipment.[Company Name] takes pride in offering customizable solutions to our clients. We understand that every project has unique requirements, making it essential to provide expansion joints tailored to specific needs. With the expertise and experience of our design team, we can create bespoke expansion joints that meet the most demanding engineering standards.Furthermore, we ensure timely delivery of our products to avoid any delays in project execution. Our commitment to customer satisfaction extends beyond the sale, as we provide comprehensive after-sales support to ensure seamless integration and operation of our expansion joints.In conclusion, [Company Name] is a trusted supplier of Pipe Rubber Bellows Expansion Joints known for delivering high-quality products that meet the diverse needs of our clients. Our dedication to continuous improvement, advanced technology, and exceptional customer service has positioned us as a market leader. We strive to remain at the forefront of the industry by constantly innovating and providing reliable solutions that exceed expectations.Note: The above content is a generic introduction to a company specializing in Pipe Rubber Bellows Expansion Joints. Please replace [Company Name] with the appropriate company name and add relevant product information as per your actual company's offerings.

Guide to Installing and Maintaining Expansion Joints for Piping Systems

Steel Pipe Expansion Joint: An Essential Component in Industrial Piping SystemsPiping systems are an integral part of any industrial plant or facility. They ensure the smooth flow of liquids, gases, and other substances through various processes and operations. However, as these substances move through the piping system, temperatures, pressure, and other factors can cause the pipes to expand or contract, leading to stress and damage.This is where expansion joints come in. Expansion joints are flexible connections that allow for movement in piping systems due to thermal expansion and contraction. They help prevent damage to pipes, fittings, and other components, while ensuring the safety and reliability of the entire system.Types of Expansion JointsThere are several types of expansion joints available for different applications. The most common types include:1. Bellows Expansion Joints: These are the most flexible type of expansion joints and are commonly used in high-temperature applications where thermal movement is significant.2. Metal Expansion Joints: These joints are constructed of metal plates, and their performance is dependent on the material used in their construction.3. Rubber Expansion Joints: These joints are made of rubber and are used in low-pressure applications, where temperature fluctuations are less severe.Installation and Maintenance of Expansion JointsProper installation and maintenance of expansion joints are crucial to ensuring their effectiveness and longevity. Here are some key steps to follow:1. Inspection Before Test: Before any testing, ensure that the expansion joint is properly installed, and all components are correctly aligned. Check for any signs of damage or defects.2. Inspection During and After Test: During testing, visually inspect the expansion joint for any signs of leaks or movement. After testing, inspect the joint again to ensure that it has returned to its original position.3. Periodic In-service Inspections: Regularly inspect the expansion joint for any signs of wear and tear. This includes checking the bellows for any signs of fatigue, such as cracks or corrosion.4. System Upgrades: When upgrading or modifying the piping system, ensure that the expansion joint remains compatible and can accommodate any changes in temperature, pressure, or flow.Benefits of Steel Pipe Expansion JointsSteel pipe expansion joints are an ideal solution for high-temperature applications and corrosive environments. They offer the following benefits:1. High Temperature Resistance: Steel expansion joints can withstand high temperatures, making them ideal for use in industrial boilers, furnaces, and other high-temperature equipment.2. Corrosion Resistance: Steel expansion joints are resistant to corrosion and rust, making them suitable for use in highly corrosive environments.3. Longevity: Steel expansion joints have a long service life and require minimal maintenance.4. Versatility: Steel expansion joints are available in a variety of sizes and configurations to suit specific piping system requirements.ConclusionSteel pipe expansion joints are an essential component in industrial piping systems, ensuring the safety, reliability, and longevity of the entire system. Proper installation and maintenance are critical to their effectiveness, and regular inspections can prevent costly repairs and downtime. As always, it is important to consult with a qualified engineer or supplier to ensure that the right expansion joint is selected for each specific application.

When it comes to piping systems, flexible connectors such as single sphere rubber expansion joints are crucial components. These devices are designed to connect piping sections while providing flexibility for movement and vibration isolation. In this blog, we will explore the features, benefits, and applications of the single sphere rubber expansion joint.The single sphere rubber expansion joint is made of two flanges with a rubber sphere in between. The flanges can be made of various materials such as carbon steel, stainless steel, or PVC. The rubber sphere is typically made of EPDM, Nitrile, or Neoprene, depending on the application requirements.One of the most significant benefits of a single sphere rubber expansion joint is its ability to absorb movement and vibration. When a piping system is in operation, it may experience thermal expansion and contraction, vibration, and other movements. These movements can cause stress on the piping system, leading to fatigue and failure. The single sphere rubber expansion joint can absorb these movements, reducing stress on the system and increasing the longevity of the piping.Another benefit of a single sphere rubber expansion joint is that it can compensate for misalignment and offset. When two piping sections are not in perfect alignment, the single sphere rubber expansion joint can compensate for the difference, reducing stress and preventing leaks.Single sphere rubber expansion joints are used in various industries, including HVAC, water treatment, chemical processing, and power generation. In HVAC systems, these flexible connectors are used to absorb vibrations caused by pumps, fans, and compressors. In water treatment plants, they are used to compensate for thermal expansion and contraction caused by changes in water temperature. In chemical processing plants, they are used to absorb movements caused by the flow of chemicals. In power generation plants, they are used to absorb movements caused by the vibration of turbines and generators.In conclusion, the single sphere rubber expansion joint is a crucial component of piping systems. Its ability to absorb movement and vibration, compensate for misalignment and offset, and its versatility make it an ideal choice for a wide range of applications. If you are looking for a reliable and cost-effective solution for your piping system, consider the single sphere rubber expansion joint.