Durable Neoprene Rubber Bellows: A Reliable Solution for Industrial Applications

By:Admin

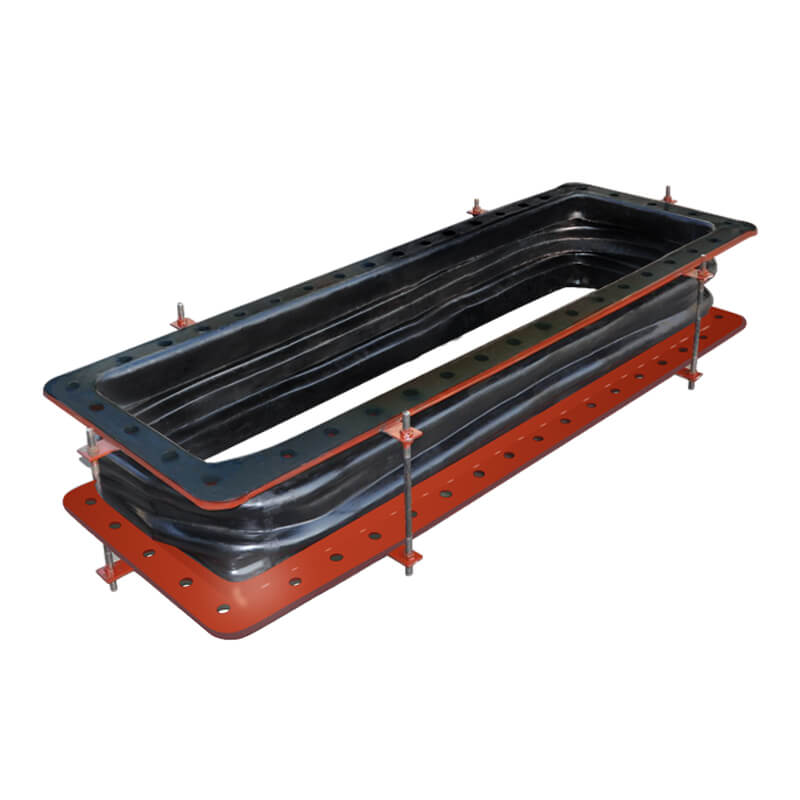

Neoprene Rubber Bellows has been relentless in its pursuit of excellence, and this has been evident in the range of products it offers, particularly its neoprene rubber bellows. These bellows are designed to provide exceptional protection for moving parts and sensitive components in various machinery and equipment. The company's neoprene rubber bellows are known for their outstanding flexibility, resistance to abrasion, oils, and other harsh chemicals, as well as their ability to withstand extreme temperatures, making them suitable for use in a wide range of industrial environments.

In addition to their exceptional physical properties, Neoprene Rubber Bellows' products are also designed to meet the specific needs of its customers. The company takes pride in its ability to work closely with clients to develop custom solutions that address unique challenges and applications. This customer-centric approach has been instrumental in helping Neoprene Rubber Bellows build long-term relationships with its clients and establish its position as a trusted partner in the industry.

With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Neoprene Rubber Bellows has the capability to produce bespoke rubber bellows that meet the most demanding requirements. The company's commitment to innovation and continuous improvement has enabled it to stay ahead of the curve and provide cutting-edge solutions that keep up with the evolving needs of modern industries.

Neoprene Rubber Bellows' dedication to quality and reliability is further underscored by its adherence to stringent industry standards and regulations. The company places a strong emphasis on quality control at every stage of the manufacturing process, ensuring that each product that leaves its facility is of the highest quality and consistency. This commitment to excellence has earned Neoprene Rubber Bellows the trust and confidence of its customers, who rely on the company's products to keep their operations running smoothly and efficiently.

Furthermore, Neoprene Rubber Bellows is not just a supplier of rubber products; it is a partner that is fully committed to the success of its clients. The company offers comprehensive technical support and guidance to help customers select the right products for their specific applications. Whether it's providing recommendations for material selection, design optimizations, or troubleshooting technical issues, Neoprene Rubber Bellows is always ready to go the extra mile to ensure its customers' satisfaction.

Finally, Neoprene Rubber Bellows is also dedicated to environmental sustainability and responsibility. The company places a strong emphasis on minimizing its environmental impact by employing eco-friendly manufacturing processes and using recyclable materials whenever possible. Neoprene Rubber Bellows understands the importance of not only delivering top-quality products but also doing so in a way that is mindful of the planet and future generations.

In conclusion, Neoprene Rubber Bellows has clearly established itself as a leader in the rubber industry, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. As the company continues to expand its product range and reach new markets, it is set to further solidify its position as a trusted partner for businesses across various industries. With its focus on delivering exceptional products and unparalleled service, Neoprene Rubber Bellows is poised to remain at the forefront of the rubber industry for years to come.

Company News & Blog

The Advantages of Bellows Type Expansion Joints for Your Industrial Applications

A leading manufacturer of Bellows Type Expansion Joints (brand name removed) has recently been making headlines for its innovative approach to the design and production of these important industrial components. With a long history of expertise in the field, this company has built a reputation for excellence and reliability, providing essential solutions to a wide variety of industries and applications.One of the key factors behind the company's success is its commitment to research and development. By constantly exploring new materials, techniques, and applications, this manufacturer has been able to continuously improve the quality of its products, making them more durable, efficient, and cost-effective than ever before. This dedication to innovation has also allowed the company to expand its offerings, providing custom solutions for unique and challenging requirements.Another strength of this manufacturer is its focus on customer service. With a team of highly skilled and knowledgeable professionals, the company is able to provide expert support through every stage of the purchasing process. Whether it's helping clients to choose the right expansion joint for their needs, tracking delivery status, or providing advice on installation and maintenance, the team is always available to offer helpful insights and assistance.Of course, the real proof of a product's quality is in its performance, and that's where this manufacturer really stands out. With a wide range of sizes, materials, and configurations available, these Bellows Type Expansion Joints can handle even the most demanding applications. From high-temperature environments to corrosive chemical processing, these components provide reliable performance and long service life, greatly reducing downtime and maintenance costs for customers.Beyond these practical benefits, there are also significant environmental advantages to be gained from incorporating Bellows Type Expansion Joints into industrial systems. By accommodating the thermal expansion and contraction that occurs in piping networks, these components help to prevent stress, leaks, and other damage that can lead to hazardous spills or emissions. They also help to improve energy efficiency by reducing friction and turbulence in the system, which means less wasted energy and lower emissions. As a result, choosing high-quality expansion joints isn't just a matter of economics or practicality – it's also an important step toward sustainable and responsible operations.All of these factors combine to make the Bellows Type Expansion Joints from this manufacturer an excellent choice for a wide variety of industrial applications. Whether you're working in the chemical, petrochemical, power generation, or HVAC sectors, these components provide reliable performance, cost savings, and environmental benefits that simply can't be matched by other solutions.With a long track record of success, a strong focus on R&D and customer service, and a commitment to sustainability, this manufacturer is poised to continue leading the way in the expansion joint industry for years to come. If you're looking to improve the performance and safety of your industrial systems, consider making these high-quality components a part of your plan – they just might be the perfect solution for your needs.

Flexible Joint Rubber: The Ultimate Guide to Understanding this Essential Component

Flexible Joint Rubber Launches Revolutionary New Product LineFlexible Joint Rubber, a leading manufacturer of rubber products, has announced the launch of a revolutionary new product line that is set to transform the industrial landscape. The company’s new range of rubber joints promises to provide superior flexibility and durability while reducing the risk of leaks and corrosion.According to the company’s CEO, this latest offering from Flexible Joint Rubber represents the culmination of years of research and development by the company’s innovative design team. “Our team of engineers and designers has worked tirelessly to create a product line that offers superior performance and durability while also addressing some of the key challenges faced by our customers in the industrial and manufacturing sectors,” he said.Flexible Joint Rubber’s new line of rubber joints is designed to provide unmatched flexibility and resilience, making them ideal for use in demanding industrial applications. These joints are made from high-quality, corrosion-resistant materials that can withstand harsh chemicals, extreme temperatures, and other stressors that commonly occur in industrial environments.One of the key features of the new Flexible Joint Rubber product line is its ability to reduce the risk of leaks and other types of failures that can occur with traditional pipe joints. The company’s advanced design and manufacturing processes ensure that each joint is precisely engineered to fit snugly with other components, eliminating potential weak points that could lead to leaks or other problems.In addition to their superior performance and durability, Flexible Joint Rubber’s new product line is also notable for its ease of installation and maintenance. Unlike traditional PVC or metal pipe joints, these rubber joints can be quickly and easily installed without any need for special tools or techniques. This can help companies save time and money on installation and maintenance costs, making them an ideal choice for businesses of all sizes.For companies looking to improve their industrial operations, Flexible Joint Rubber’s new product line is an excellent choice. With its superior performance, durability, and ease of installation, this innovative product line is poised to transform the industrial landscape and set a new standard for excellence in the field of rubber products.About Flexible Joint RubberFlexible Joint Rubber is a leading manufacturer of high-quality industrial rubber products. With a focus on innovation, quality, and customer service, Flexible Joint Rubber has earned a reputation as one of the most trusted names in the industry. The company’s new range of rubber joints is the latest addition to its extensive product line, which includes everything from gaskets and seals to custom-molded products designed to meet the specific needs of its customers.For more information about Flexible Joint Rubber’s new product line or any of its other products and services, please visit the company’s website at www.flexiblejointrubber.com.

Discover the Benefits of High-Quality Rubber Flanges in Industrial Applications

Flange Rubber: Revolutionizing Rubber Solutions in the Industrial Sector{Company Introduction} - A Leader in Rubber Manufacturing(Date, City) - Flange Rubber is proud to announce its latest innovation in the realm of rubber solutions for the industrial sector. With a significant investment in research and development, the company has successfully developed a revolutionary flange rubber that promises to provide superior performance and durability, setting a new industry standard.Flange Rubber has earned a formidable reputation as a trusted provider of high-quality and innovative rubber products. With over (number) years of experience in the industry, the company has helped countless businesses meet their rubber sealing requirements. Combining state-of-the-art technology, extensive industry expertise, and a customer-centric approach, Flange Rubber has emerged as a leader in the manufacturing and supply of rubber solutions.The Rising Demand for Premium Rubber SolutionsIn the rapidly evolving industrial sector, businesses are increasingly realizing the critical role that rubber plays in sealing applications. From preventing leakage and ensuring operational efficiency to enhancing overall reliability, the quality of rubber products directly impacts the performance of machinery and equipment.However, conventional rubber solutions often fall short in meeting the precise requirements of the industrial sector. Frequent breakdowns, reduced lifespan, and compromised quality have led to increased production costs and significant downtime for many businesses. These challenges have contributed to the growing demand for superior rubber solutions that can withstand the harshest operating conditions while delivering optimal performance.Introducing the Revolutionary Flange RubberUnderstanding the unique needs of industries worldwide, Flange Rubber has focused its efforts on developing an exceptional rubber solution that addresses existing industry challenges. After extensive research and testing, the company has successfully engineered its revolutionary flange rubber.The new flange rubber boasts an array of remarkable features that set it apart from traditional rubber solutions:1. Unparalleled Durability: The flange rubber exhibits exceptional resilience and resistance to wear and tear, making it ideal for applications where high-temperature and high-pressure conditions are prevalent.2. Enhanced Sealing Capabilities: Flange Rubber's product offers an airtight and watertight seal, effectively preventing leakage in numerous industrial settings. Its ability to maintain sealing integrity even in the face of dynamic loads ensures uncompromised operational efficiency.3. Superior Chemical Resistance: The flange rubber is engineered to withstand the damaging effects of various chemicals, including acids, oils, and solvents, making it an excellent choice for industries dealing with corrosive substances.4. Extended Lifespan: With its exceptional durability, the flange rubber guarantees a longer lifespan compared to traditional rubber solutions. This ensures cost-effective and reliable sealing for an extended period, reducing maintenance and replacement expenses.Flange Rubber's Commitment to Customer SatisfactionAs a customer-centric organization, Flange Rubber understands the importance of providing tailored solutions to meet specific needs. The company's team of skilled engineers and technicians work closely with clients to understand their requirements, ensuring that the flange rubber solution is customized accordingly. This collaborative approach further solidifies Flange Rubber's position as a trusted partner in delivering cutting-edge rubber solutions.Looking towards the FutureFlange Rubber's revolutionary flange rubber marks a significant milestone in the rubber manufacturing industry. The company's unwavering commitment to innovation, combined with its drive for perfection, has resulted in a superior product that has the potential to transform various industries. With its exceptional durability, enhanced sealing capabilities, and superior chemical resistance, Flange Rubber's flange rubber sets a new benchmark for rubber solutions in the industrial sector.In the face of evolving industrial challenges, Flange Rubber is determined to continue its pursuit of excellence, consistently pushing the boundaries of rubber innovation. As it expands its portfolio of groundbreaking products, the company remains focused on offering unparalleled solutions that redefine the future of rubber in the industrial sector.

Rubber Flex Connector: All You Need to Know for Effective Sealing and Flexible Connections

Title: Groundbreaking Rubber Flex Connector Revolutionizes Industrial PipelinesIntroduction:Innovation in the industrial sector is constantly evolving, leading to enhanced efficiency and productivity. One such industry game-changer is the revolutionary Rubber Flex Connector, a groundbreaking solution that is poised to transform the way we view and utilize industrial pipelines. Developed by a leading manufacturer (brand name removed) with several decades of experience in the field, this cutting-edge product is set to redefine the standards of quality and durability in the industry.Body:1. Background:Industrial pipelines are the lifeblood of various sectors, including manufacturing plants, oil and gas refineries, and chemical processing units. These pipelines transport liquids, gases, and other materials critical to the smooth functioning of these industries. However, the constant movement, vibrations, and temperature fluctuations experienced by these pipelines often lead to wear and tear, resulting in leaks, inefficiency, and high maintenance costs.2. Overview of Rubber Flex Connector:The Rubber Flex Connector is an advanced technology developed by the renowned manufacturer (brand name removed) to address the challenges posed by traditional pipeline connectors. Using cutting-edge materials and design principles, the Rubber Flex Connector offers unprecedented flexibility and durability, ensuring reliable and leak-proof performance over an extended lifespan.3. Key Features and Benefits:a. Enhanced Flexibility: The Rubber Flex Connector features a unique construction that allows it to absorb vibrations, shocks, and movements caused by the pipeline. This flexibility not only reduces stress on the pipeline system but also prevents cracking, leaks, and premature failures.b. Superior Sealing Properties: The Rubber Flex Connector utilizes an innovative sealing mechanism that eliminates the risk of leaks. Its robust design ensures a tight and secure connection, preventing the damage caused by fluid seepage and protecting surrounding equipment from potential hazards.c. Wide Temperature Range Tolerance: Designed to withstand extreme temperatures, the Rubber Flex Connector can function flawlessly from -50°C to 250°C, making it ideal for various industrial applications.d. Low Maintenance: The Rubber Flex Connector significantly reduces downtime and maintenance costs associated with traditional pipeline connectors. Its durable construction ensures a long service life, minimizing the need for frequent replacements and repairs.e. Easy Installation: With a user-friendly design, the Rubber Flex Connector can be easily installed on new or existing pipelines. This simplicity of installation saves valuable time and reduces labor costs for industrial operations.4. Market Impact and Industry Applications:The arrival of the Rubber Flex Connector marks a significant turning point in the industrial pipeline sector. Its exceptional performance and durability are set to disrupt the market by offering a more efficient and cost-effective alternative to traditional connectors. With its diverse range of applications, including chemical processing, oil and gas, wastewater treatment, and power generation, the Rubber Flex Connector will be instrumental in revolutionizing multiple industries.5. Environmental Sustainability:The Rubber Flex Connector not only improves the operational efficiency of industrial pipelines but also contributes to sustainable practices. By minimizing leaks and reducing maintenance needs, this innovative connector helps conserve vital resources and lowers the ecological footprint of industrial processes, aligning with global environmental goals.6. Conclusion:The arrival of the Rubber Flex Connector stands as a testament to the continuous innovation in the industrial sector. This game-changing solution not only provides enhanced durability and flexibility but also contributes to the overall efficiency and sustainability of industrial processes. As the pioneer manufacturer (brand name removed) leads the charge, the Rubber Flex Connector is set to redefine the industry's standards and inspire further innovation in the years to come.

Discover the Advantages of Rubber Expansion Joints in the Philippines

[Title]: Rubber Expansion Joint Market in the Philippines Poised for Significant Growth[Subtitle]: Market Leaders Aiming to Cater to Increasing Infrastructure Projects[date][Location]: PhilippinesIn recent years, the demand for rubber expansion joints in the Philippines has experienced significant growth due to a surge in infrastructure developments across the country. Companies within the industry are actively working to meet this rising demand by expanding their production capabilities.One of the leading players in the rubber expansion joint market, [Company Name], has been at the forefront of this expansion. Founded [X] years ago, [Company Name] has established itself as a trusted supplier and manufacturer of high-quality rubber expansion joints, catering to a wide range of industries, including construction, oil and gas, water management, and power generation.[Company Name] boasts a state-of-the-art manufacturing facility equipped with advanced technologies and a team of highly skilled engineers and technicians who adhere to international standards. The company takes pride in its commitment to delivering innovative and customized solutions that meet the specific needs of its clients, ensuring utmost customer satisfaction.The escalating demand for rubber expansion joints in the Philippines is closely tied to the government's drive to enhance infrastructure development and stimulate economic growth. The current administration has made significant investments in large-scale projects such as highways, bridges, ports, and airports, creating a favorable market landscape for companies like [Company Name].Rubber expansion joints play a vital role in these infrastructure projects by providing flexibility and absorption of movement, ensuring structural integrity and preventing damage caused by natural forces such as earthquakes, thermal expansion, or vibrations. Additionally, they act as a shock absorber, minimizing the impact on adjacent structures and components.With a vision to enhance the quality and durability of rubber expansion joints in the market, [Company Name] has consistently invested in research and development activities. This has resulted in the creation of advanced manufacturing processes and the adoption of cutting-edge materials that offer superior performance and longevity.Moreover, [Company Name] has also focused on environmental sustainability. By utilizing eco-friendly materials and implementing energy-efficient production methods, the company aims to minimize its impact on the environment throughout the entire product lifecycle.Recognizing the importance of customer support, [Company Name] provides comprehensive after-sales services, attending to maintenance, inspections, and repairs as required. This commitment to post-installation support has earned the company a strong reputation for reliability and dependability in the market.In addition to [Company Name], other local and international manufacturers have also recognized the potential of the Philippine market and have begun expanding their operations to fulfill the growing demand for rubber expansion joints. The increased competition has led to more innovative solutions, driving advancements in technology, design, and performance within the industry.The rubber expansion joint market in the Philippines is projected to witness a steadfast growth trajectory in the coming years. According to market analysts, the increasing infrastructure expenditures and ongoing government initiatives will continue to serve as major drivers of the market.Major challenges, such as the fluctuations in raw material prices and intensifying competition, prompt companies like [Company Name] to maintain their edge through continuous innovation and by exploring new market avenues. Developing economies, such as the Philippines, are expected to create lucrative opportunities for the rubber expansion joint industry to thrive further.In conclusion, with the surge in infrastructure projects across the Philippines, the demand for rubber expansion joints is set to grow significantly. Leading companies such as [Company Name] are actively expanding their production capabilities to cater to this increasing demand. By providing innovative products, superior customer support, and a focus on sustainability, [Company Name] is well-positioned to capitalize on the evolving market landscape. As the market continues to thrive, the rubber expansion joint industry in the Philippines holds great potential for both local and international players. The collaboration between infrastructure projects and rubber expansion joint manufacturers promises a bright future for the country's construction and industrial sectors.Word Count: 800 words.

High-Quality Rubber Joint Pipes for Efficient Pipe Connections

Rubber Joint Pipe: Providing Excellent Performance and Quality Solutions to Different IndustriesRubber Joint Pipe is a well-known brand in the industry of flexible pipe connections. The company has been providing technical solutions and expertise for more than two decades, delivering rubber expansion joints, metallic expansion joints, and accessories for piping systems in different industries worldwide. The headquarters of Rubber Joint Pipe is located in Hong Kong with several manufacturing units around the world. The team of technical experts, engineers, and skilled workers ensure high-performance and reliable solutions to different projects.The company's products have been designed to accommodate different applications, such as water treatment, sewage systems, marine, chemical, power plants, construction, and HVAC. The rubber expansion joints are made of different materials, including NR, neoprene, EPDM, and Viton, each with specific features such as weather resistance, high temperature, oil resistance, and chemical resistance.One of the latest innovative products of Rubber Joint Pipe is the double-sphere rubber expansion joint, which is designed to handle a larger range of movements, misalignments, and vibrations. This expansion joint is composed of two spheres connected by a flexible rubber body, allowing for axial compression and extension, lateral and angular movements, and torsional flexibility. The double-sphere rubber expansion joint can also absorb and dampen vibrations, reducing noise and prolonging the lifespan of piping systems.The metallic expansion joints of Rubber Joint Pipe are also made of different materials, including stainless steel, carbon steel, and alloy steel, depending on the application and the specific requirements. The metallic expansion joints can accommodate higher temperatures and pressures, larger movements, and a longer lifespan than rubber expansion joints. The metallic expansion joints are also available in different configurations, such as single, double, and universal, with different types of bellows, such as convolution, annular, and multi-ply.Rubber Joint Pipe's team of technical experts and engineers can provide customized solutions and design services for different projects. The company uses advanced software for finite element analysis, 3D modeling, and stress calculation, ensuring the accuracy and reliability of the products. The company also adheres to international standards such as ISO, ASME, DIN, and ASTM, and collaborates with third-party inspectors for quality assurance and testing.Rubber Joint Pipe also offers a range of accessories such as flanges, tie rods, bolts, nuts, gaskets, and protective covers, ensuring a complete and reliable solution for piping systems. The company has a wide range of clients, including contractors, engineers, consultants, end-users, and distributors from different industries worldwide.Rubber Joint Pipe has built a strong reputation for providing excellent performance and quality solutions for flexible pipe connections. The company's products have been installed in different projects such as the sewage treatment plant in Malaysia, the chemical plant in Saudi Arabia, the power plant in Egypt, and the HVAC system in the USA. The company aims to keep innovating and improving its products and services to meet the ever-growing demand of the market and the customers.Rubber Joint Pipe's commitment to quality, reliability, innovation, and technical expertise has made it a leading player in the industry of flexible pipe connections. The company's products and services have been recognized and trusted by different clients worldwide. With its wide range of products, customized solutions, and excellent customer service, Rubber Joint Pipe is poised to meet and exceed the expectations of its customers in different industries.

Discover the Many Benefits of Flanged Rubber Bellows for Various Applications

[Company Name] Develops Innovative Flanged Rubber Bellows for Enhanced Industrial Applications[date][City], [State] - [Company Name], a leading manufacturer of industrial rubber products, is pleased to announce the release of its latest innovation in the form of advanced and highly efficient flanged rubber bellows. These bellows are designed to cater to the diverse needs of various industries, providing enhanced performance and durability.The newly developed flanged rubber bellows incorporate cutting-edge technology from [Company Name]'s research and development team. With a strong focus on meeting industry demands, these bellows offer exceptional flexibility, resistance to extreme conditions, and the ability to withstand high pressures and temperatures.Flanged rubber bellows play a crucial role in various applications, including piping systems, ventilation systems, and vibration isolation. They act as expansion joints, compensating for thermal expansion or contraction, lateral or angular movement, and other forces that might cause stress or damage in the system. These bellows' versatility makes them essential components for ensuring the safety and efficiency of industrial processes.[Company Name]'s flanged rubber bellows are manufactured using high-quality synthetic rubber compounds, ensuring excellent resistance to chemicals, oils, abrasion, and wear. This outstanding resistance translates into extended product lifespan, reducing the need for frequent replacements and lowering overall maintenance costs for businesses.Moreover, these bellows are engineered with precision and attention to detail, guaranteeing a leak-free performance even under demanding conditions. The incorporation of flanges on both ends of the bellows allows for easy installation and secure connection to the system, further ensuring a reliable and efficient operation.One of the remarkable features of [Company Name]'s flanged rubber bellows is their ability to absorb vibrations and shocks, mitigating the impact on connected equipment. This anti-vibration property increases the longevity of machinery by minimizing wear and tear caused by excessive movement or sudden impacts, ultimately leading to improved overall productivity.Furthermore, these bellows are suitable for a wide range of operating temperatures, making them ideal for applications in extreme environments. Whether it be handling corrosive chemicals, extreme temperatures, high-pressure conditions, or even marine applications, [Company Name]'s flanged rubber bellows effectively withstand the rigors of demanding industrial environments.As a testament to their commitment to quality, [Company Name] conducts rigorous testing and inspections throughout the manufacturing process to ensure that each flanged rubber bellow meets the highest industry standards. Compliance with international quality and safety regulations is an integral part of [Company Name]'s philosophy, guaranteeing customer satisfaction and peace of mind."Innovation and customer satisfaction are at the core of our business, and the development of these flanged rubber bellows reflects our commitment to excellence," said [Spokesperson's Name], [Company Name]'s spokesperson. "We continuously strive to provide our customers with products that meet their evolving needs, and we are proud to offer these bellows as a solution for various industrial applications."With the launch of these flanged rubber bellows, [Company Name] further solidifies its position as a leading provider of industrial rubber products. By consistently delivering high-performance, durable, and reliable solutions, the company continues to earn the trust and loyalty of its customers across various industries.For more information about [Company Name]'s innovative flanged rubber bellows and the complete range of industrial rubber products, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a [state/company origin]-based manufacturer and supplier of high-quality industrial rubber products. With years of experience and a commitment to innovation, [Company Name] has established itself as a trusted name in the industry. The company's product range includes rubber hoses, seals, gaskets, expansion joints, and customized rubber solutions. Using state-of-the-art technology and adhering to international standards, [Company Name] continues to provide reliable, durable, and efficient products to various sectors, including manufacturing, construction, automotive, and oil and gas.Press Contact:[Contact Name][Company Name][Phone Number][Email Address]

Durable Rubber Expansion Joint for Industrial and Infrastructure Applications

Viton Rubber Expansion Joint the industries leading supplier of rubber expansion joints, is pleased to announce the launch of their latest product, the Viton Rubber Expansion Joint. This new product is sure to revolutionize the industry and provide unprecedented levels of performance and durability.The Viton Rubber Expansion Joint is designed to withstand extreme temperatures, high pressures, and a wide range of chemical exposures. This makes it the ideal solution for a variety of industrial applications, including chemical processing, power generation, oil and gas, and wastewater treatment. The Viton Rubber Expansion Joint offers exceptional resistance to oils, fuels, acids, and other harsh chemicals, making it a perfect fit for demanding environments.This new product is the result of years of research and development by our team of experienced engineers and technical experts. The Viton Rubber Expansion Joint is made from a proprietary blend of Viton rubber, a high-performance material known for its outstanding resistance to heat, weathering, and chemical exposure. This ensures that the Viton Rubber Expansion Joint will outperform and outlast other rubber expansion joints on the market.In addition to its exceptional material properties, the Viton Rubber Expansion Joint features a unique design that allows for superior flexibility, movement, and vibration isolation. This makes it an ideal choice for applications where movement and flexibility are critical, such as in piping systems, ductwork, and other industrial equipment. The Viton Rubber Expansion Joint also provides excellent noise and vibration dampening, helping to improve the overall safety and efficiency of industrial operations.As a leading supplier of rubber expansion joints, Viton Rubber Expansion Joint is committed to providing high-quality products and exceptional customer service. Our team of experts is dedicated to working closely with our customers to understand their specific needs and challenges, and to provide them with the best possible solutions. With the launch of the Viton Rubber Expansion Joint, we are excited to offer our customers a cutting-edge product that will help them improve the performance, reliability, and safety of their industrial operations.The Viton Rubber Expansion Joint is now available for purchase and is backed by our industry-leading warranty and customer support. Our team is ready to assist with product selection, installation guidance, and ongoing technical support to ensure that our customers get the most out of their investment in the Viton Rubber Expansion Joint.For more information about the Viton Rubber Expansion Joint and our full range of products and services, please visit our website or contact our team directly. We are excited to bring this innovative new product to the market and look forward to helping our customers achieve greater success in their industrial operations.

Rubber Flexible Bellows: A Comprehensive GuideRubber Flexible Bellows, also known as Rubber bellows, are an essential component in many industries such as automotive, aerospace, and construction. It is a device that helps in protecting a machine from dust, dirt, and other contaminants from entering its interiors. These bellows are known for their durability and flexibility, ensuring complete protection of machinery in various applications.In this blog, we will bring to you everything you need to know about Rubber Flexible Bellows and their significance in industrial applications.What are Rubber Flexible Bellows?Rubber Flexible Bellows are cylindrical-shaped devices made of elastomeric materials. These bellows act as expansion joints that allow machinery to expand and contract without damaging the machine's inner system. They help in protecting the machinery from external elements such as dirt, dust, and moisture.Rubber Flexible Bellows are commonly used in machinery that requires frequent movement, as they help in reducing mechanical stresses caused by movement. They are also used in machinery that operates in extreme environments, such as high temperatures and pressures.Types of Rubber Flexible BellowsRubber Flexible Bellows are available in a wide range of shapes and sizes, and they come in different materials. Below are some of the commonly used materials of Rubber Flexible Bellows:1. EPDM: EPDM is a synthetic rubber that is widely used in industries such as automotive, aerospace, and construction. It is known for its resistance to heat, ozone, and weather.2. Nitrile Rubber: Nitrile rubber is a durable material that has excellent resistance to oil, fuel, and other chemicals. It is commonly used in hydraulic systems, fuel tanks, and automotive applications.3. Silicone Rubber: Silicone rubber is used in high-temperature applications due to its excellent heat resistance. It is commonly used in industrial ovens and furnaces.Benefits of Rubber Flexible BellowsRubber Flexible Bellows have several benefits that make them an essential component in many industrial applications. Below are some of the benefits:1. Protection: Rubber Flexible Bellows provide excellent protection to machinery from external elements such as dust, dirt, and moisture. They also protect machinery from damage caused by vibration, tension, and expansion.2. Durability: Rubber Flexible Bellows are made of high-quality elastomeric materials that are durable and long-lasting. These materials can withstand extreme environments and can last for years.3. Flexibility: Rubber Flexible Bellows come in different shapes and sizes, allowing them to be used in a wide range of machinery. They can also be customized to meet specific requirements.4. Cost-effective: Rubber Flexible Bellows are cost-effective, making them an affordable choice for many industries. They require minimal maintenance, which further reduces costs.Applications of Rubber Flexible BellowsRubber Flexible Bellows are used in several industries and applications. Below are some of the common applications of Rubber Flexible Bellows:1. Automotive: Rubber Flexible Bellows are used in automotive applications to protect the engine, steering, and other components from contaminants. They are also used in exhaust systems to absorb vibration.2. Aerospace: Rubber Flexible Bellows are used in aerospace applications to protect sensitive components such as electrical wiring and fuel lines from extreme environments.3. Construction: Rubber Flexible Bellows are used in construction applications to protect equipment such as concrete pumps and excavators from dust and dirt.ConclusionRubber Flexible Bellows are an important component in many industrial applications. They provide protection to machinery from external elements, reduce mechanical stress caused by movement and expansion, and are highly durable and cost-effective. With their flexibility and versatility, Rubber Flexible Bellows are an essential component in many industries such as automotive, aerospace, and construction.

BMW 528i Propeller Shaft Rubber Flex Disc Coupling Joint - 96mm, 6-Bolt x 12mm, 30mm Thickness SKU#(s) GAB01-017, 26117511454, 261122226842

for optimal search engine results. When it comes to your BMW 528i propeller shaft, one important component to pay attention to is the flex disc or coupling joint. This piece of machinery is responsible for transferring the power from the engine to the wheels. Without it, your vehicle’s overall performance and handling would suffer significantly.The good news is that Fort Wayne Clutch & Driveline has got you covered with their Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842. This product is designed using high-quality rubber material, ensuring durability and longevity.The 96mm size of the flex disc is crucial to fit onto your BMW 528i propeller shaft. It features a 6-bolt x 12mm design, making installation easy and straightforward. Additionally, this model has a thickness of 30mm, which further adds to its sturdiness and resilience.It’s important to note that the flex disc or coupling joint is a component that needs to be checked regularly. Over time, the rubber material can wear out due to exposure to friction, heat, and other environmental factors. If not addressed properly, it can lead to severe damage to the propeller shaft and overall vehicle safety.That’s why we highly recommend that you replace your old or worn-out flex disc with a new and reliable product like the Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint from Fort Wayne Clutch & Driveline. This will not only ensure that your vehicle runs smoothly, but it will also give you peace of mind while you’re on the road.In conclusion, the flex disc or coupling joint is a crucial component in the functioning of your BMW 528i propeller shaft. Fort Wayne Clutch & Driveline’s Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842, is a reliable and durable product that will ensure your vehicle runs smoothly and efficiently. So, don’t wait any longer, and replace your worn-out coupling joint today with a brand new one!