Discover the Benefits of Metal Bellows Packless Expansion Joints

By:Admin

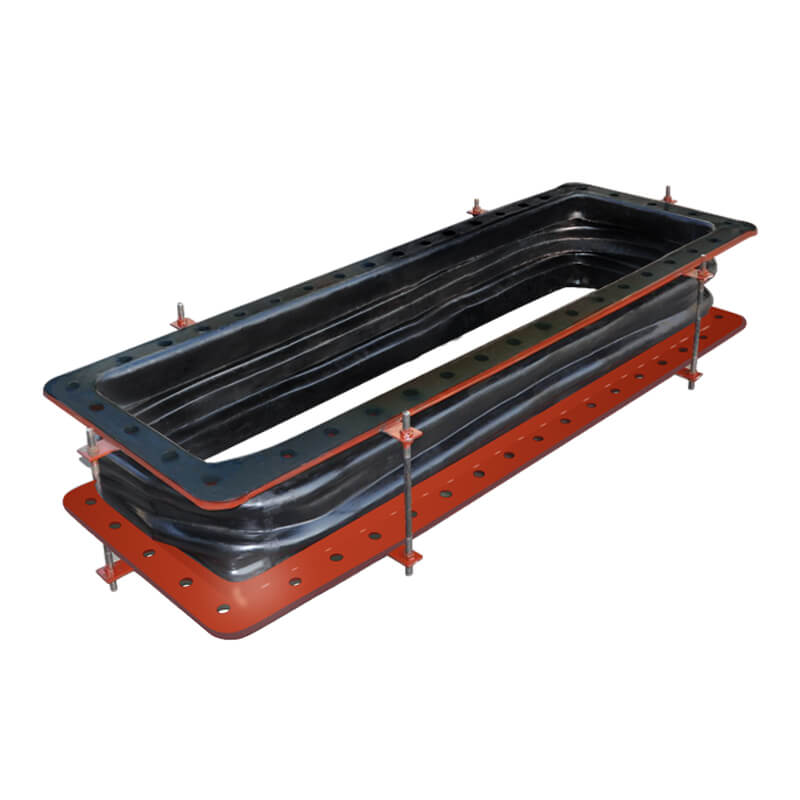

The use of pipes in various industries like manufacturing, aerospace, and oil and gas requires certain devices that can help in accommodating the expansion and contraction of the pipes due to temperature changes. One such device that is gaining popularity in the market is the Metal Bellows Packless Expansion Joint.

Metal Bellows Packless Expansion Joints are flexible pipe connectors that help in reducing the stresses caused by the thermal expansion and contraction of pipes. They are designed to accommodate axial, lateral, and angular movement of pipes without changing the direction of the flow, making them a perfect solution for piping systems that require a high degree of flexibility and durability.

The Metal Bellows Packless Expansion Joints are made of high-quality metal alloy bellows that can withstand high temperatures and pressure fluctuations. These joints are specially designed to provide a leak-proof seal, eliminating the risk of fluid leakage and ensuring the safety of the overall piping system.

One of the key advantages of Metal Bellows Packless Expansion Joints is their long service life. These expansion joints are highly durable and resistant to wear and tear, ensuring that they provide a reliable solution for the long term.

Another benefit of Metal Bellows Packless Expansion Joints is their ease of installation. They come in various sizes and configurations to fit different types of piping systems. This makes them easy to install and maintain, reducing the overall downtime of the system.

At {company name}, we are committed to providing our customers with the best quality Metal Bellows Packless Expansion Joints. Our expansion joints are manufactured using state-of-the-art technology, ensuring that they meet the highest industry standards.

Our team of experts works closely with our clients to understand their specific requirements and provide customized solutions. We offer a wide range of Metal Bellows Packless Expansion Joints in different sizes and configurations to meet the unique needs of our clients.

In addition to our high-quality products, we also provide exceptional customer service to our clients. Our team of experts is available round the clock to provide support and assist our clients in any way possible.

Overall, Metal Bellows Packless Expansion Joints are a reliable solution for piping systems that require flexibility and durability. With their long service life and ease of installation, these expansion joints are the future of the piping industry. If you are looking for high-quality Metal Bellows Packless Expansion Joints, {company name} is your one-stop solution!

Company News & Blog

Understanding the Importance of Expansion Joints in Construction and Engineering

In recent years, the construction industry has been rapidly expanding due to the increasing demand for infrastructure. And with this expansion comes the need for crucial components that are necessary to ensure the integrity and safety of the structures. One of these vital components is the expansion joint.An expansion joint is an essential part of a building that allows for movement between two adjacent parts of the structure. This component is designed to accommodate the expansion and contraction caused by temperature changes, thereby preventing any form of damage to the structure. With the importance of this component in mind, {company name} has introduced a new range of expansion joints that are set to revolutionize the industry.The range of expansion joints from {company name} is designed with precision and engineered to withstand extreme conditions. The joints are made from high-quality materials that can withstand high temperatures, as well as harsh weather conditions such as heavy rainfall and snow. In addition, the design of the expansion joints allows for easy installation, which reduces the time and effort required for installation.The new expansion joints from {company name} are also designed to be low maintenance. They require minimal upkeep, which helps save on maintenance costs. Moreover, they are durable and long-lasting, making them a great investment for any construction project.One of the unique features of the new expansion joints from {company name} is their compatibility with various types of structures. The company offers a range of expansion joints suitable for use in bridges, highways, buildings, and other structures. This compatibility ensures that contractors can use the expansion joints for various projects, regardless of the structure's design or size.Another significant advantage of {company name}'s expansion joints is their ability to reduce noise and vibrations. These joints help to absorb vibrations caused by the movement of structures, which in turn eliminates noise pollution. This feature makes the expansion joints an ideal choice for structures located in densely populated areas such as urban centers.{Company name} is a reputable brand known for its commitment to quality and innovation. The company has been in the construction industry for several years and has built a reputation for providing high-quality products and excellent customer service. The introduction of the new range of expansion joints is another testament to the company's dedication to meeting the needs of their customers.The expansion joints from {company name} are an excellent investment for contractors looking to maintain the integrity and safety of their structures. With their low maintenance requirements, durability, and compatibility with various structures, these expansion joints are sure to provide a significant return on investment.In conclusion, the introduction of the new range of expansion joints from {company name} marks a significant milestone in the construction industry. These joints are designed to not only withstand extreme conditions but also provide compatibility with various structures, making them an ideal choice for contractors. With {company name}'s commitment to quality and innovation, contractors can rest assured that they are getting the best products in the industry.

National Leader in Manufacturing Rubber Expansion Joints and Flex Products

Unisource Manufacturing Inc. is a well-known national leader in the manufacture of rubber expansion joints and a wide range of other flex products. The company has been providing its customers with high-quality, reliable products for over 50 years, and during that time, it has built a reputation for excellence that is second to none.One of the key products that Unisource specializes in is rubber expansion joints. These products are essential for maintaining the integrity of pipelines and other systems that rely on flexibility and durability to function properly. Specifically, rubber expansion joints allow for the movement and expansion of pipes, hoses, and other components without putting stress on the rest of the system. This helps to prevent leaks, cracks, and other damage that can lead to costly repairs and downtime.At Unisource, they understand that every customer's needs are different, which is why they offer a wide range of rubber expansion joint products to choose from. These products include spheres, spool-type joints, multiple arches, and high-pressure specs. All of these products are designed to provide superior performance, durability, and reliability, even in the most challenging environments.Unisource's rubber expansion joints are made from the highest-quality materials, including natural rubber, EPDM, neoprene, and Viton. Each product is thoroughly tested and inspected to ensure that it meets or exceeds the company's high standards for quality and reliability. This attention to detail and commitment to excellence is what sets Unisource apart from the competition.In addition to rubber expansion joints, Unisource also offers a wide range of other products, including metal hoses, industrial hoses, and hydraulic hoses. Each of these products is designed to meet the specific needs of its customers, with the same high standards of quality and performance that customers have come to expect from Unisource.Unisource's commitment to customer satisfaction doesn't end with the quality of its products. The company also provides exceptional customer service, with a team of knowledgeable and experienced professionals who are dedicated to helping customers find the right products for their needs. Whether customers need assistance with product selection, installation, or troubleshooting, the Unisource team is always there to help.In summary, Unisource Manufacturing Inc. is a national leader in the manufacture of rubber expansion joints and other flex products. With over 50 years of experience, the company has built a reputation for excellence that is second to none. Its products are designed to provide superior performance, durability, and reliability, even in the most challenging environments. And with a commitment to customer satisfaction that extends beyond the quality of its products, Unisource is the clear choice for those seeking a partner they can trust.

High-Quality Rubber Hoses for All Industries - Find Top Manufacturers and Suppliers on Alibaba.com

Rubber Pipe: The Ultimate GuideWhen it comes to transporting fluids and gases, having the right type of pipe is crucial. One type of pipe that has proved to be versatile and reliable is a rubber pipe. In this blog, we will delve deeper into rubber pipes, their types, and their uses.What is a Rubber Pipe?A rubber pipe is a flexible pipe made from rubber. These pipes can withstand high pressures and temperatures and are used to transfer oil, water, and other fluids. Rubber pipes are also used in various other industries such as automotive, mining, and chemical processing.Types of Rubber PipesThere are various types of rubber pipes, each with its specific use. Here are the commonly used types of rubber pipes:1. Silicone Rubber PipeSilicone rubber pipes are used in high-temperature applications as they can withstand very high temperatures. They can also withstand extreme cold temperatures and are used in medical, food, and beverage industries.2. Nitrile Rubber PipeNitrile rubber pipes are resistant to oil and gasoline and are used in fuel systems and hydraulic systems. They are also used in the chemical industry, where the transfer of chemicals is needed.3. Natural Rubber PipeNatural rubber pipes are flexible and have excellent elasticity. They are used in the automotive industry, where they are used in brake systems and the transport of other fluids.4. EPDM Rubber PipeEPDM (Ethylene Propylene Diene Monomer) rubber pipes are synthetic rubber pipes that are resistant to weather, ozone, and sunlight. They are used in the automotive industry, where they are used in cooling systems and in the construction of buildings.Uses of Rubber PipesRubber pipes are used in various industries and applications, including:1. Automotive industryRubber pipes are used in the automotive industry to transport various fluids such as oil, fuel, and coolant. They are also used in air filters, brake systems, and power steering systems.2. Medical industrySilicone rubber pipes are used in the medical industry for transporting fluids and gases. They are used in applications such as blood transfusions, dialysis, and drug delivery.3. Food and Beverage industrySilicone rubber pipes are used in the food and beverage industry. They are used to transfer food products such as milk and juice.4. Chemical industryRubber pipes are used in the chemical industry to transport various chemicals. They are used in applications such as acids, alcohol, and petroleum.Advantages of Rubber PipesHere are the advantages of using rubber pipes:1. Resistance to high temperatureRubber pipes can withstand high temperatures, making them ideal for use in high-temperature applications.2. Cost-effectiveRubber pipes are relatively cheaper compared to other pipe materials. This factor makes them cost-effective, especially for large-scale applications.3. FlexibilityRubber pipes are flexible and can bend without breaking. This factor makes them ideal for applications where pipes need to be flexible.4. DurabilityRubber pipes are durable and can withstand wear and tear over time. This factor ensures that they last for an extended period, thus reducing the need for frequent replacements.ConclusionRubber pipes are a versatile and reliable type of pipe that can be used in various industries and applications. With a wide variety of types available, including silicone rubber pipe, nitrile rubber pipe, natural rubber pipe, and EPDM rubber pipe, there is a rubber pipe for every application. Rubber pipes offer advantages such as resistance to high temperatures, cost-effectiveness, flexibility, and durability, making them an excellent choice for various applications.So, whenever you need a pipe that can withstand high temperatures, resist chemicals, and be flexible, think of rubber pipes. They are the ultimate solution for your piping needs.

Rubber Flexible Bellows: A Comprehensive Guide to Their Uses and Benefits

Rubber Flexible Bellows: Revolutionizing Industrial Applications[Company Name], a leading manufacturer in the rubber industry, has recently introduced a groundbreaking product known as Rubber Flexible Bellows. With an unwavering commitment to innovation and quality, [Company Name] has revolutionized the world of industrial applications with this cutting-edge solution.Rubber Flexible Bellows, as the name suggests, are bellows made from high-quality rubber materials. These flexible components serve a crucial role in numerous industries, including manufacturing, automotive, aerospace, and construction. By providing protection against dust, debris, moisture, and vibrations, Rubber Flexible Bellows are a key component in safeguarding machinery and equipment from potential damage.The superior performance of Rubber Flexible Bellows can be attributed to their inherent properties. The rubber material used in their construction exhibits exceptional durability, flexibility, and resistance to a wide range of environmental factors. This ensures that the bellows can withstand demanding operating conditions, offering long-lasting protection to the machinery they are installed on.One of the key advantages of Rubber Flexible Bellows is their ability to accommodate various types of movement. As machinery operates, there are often dynamic motions, such as expansion, contraction, or angular displacement. Rubber Flexible Bellows can effortlessly absorb and accommodate these movements, allowing for smooth and uninterrupted functioning of the equipment. This versatility makes them an ideal choice for a wide range of industrial applications.In addition to their flexibility, Rubber Flexible Bellows also excel in providing efficient sealing and insulation. Thanks to their unique design and high-quality rubber material, they create a tight seal around moving parts, preventing the entry of contaminants and ensuring the longevity of the machinery. Moreover, these bellows also provide effective insulation against noise, heat, and vibration, creating a safer and more comfortable working environment.With safety being a top priority in any industrial setting, Rubber Flexible Bellows play a crucial role in protecting both machinery and personnel. The efficient insulation properties of these bellows help in reducing noise levels, preventing hearing damage and enhancing overall comfort for workers. Furthermore, by minimizing heat transfer and vibration transmission, Rubber Flexible Bellows contribute to the prevention of accidents and injuries.[Company Name] has earned a stellar reputation in the industry for its commitment to delivering high-quality products. The Rubber Flexible Bellows undergo rigorous quality control procedures, ensuring that each unit meets the highest standards. Additionally, the company's dedicated research and development team continually strives to improve the design and performance of the bellows, staying at the forefront of technological advancements.The versatility of Rubber Flexible Bellows is further amplified by their customization options. [Company Name] offers a wide range of sizes, shapes, and materials to cater to the specific needs of different industries and applications. The company's team of experts works closely with clients to understand their requirements and provides tailored solutions that maximize efficiency and performance.As a frontrunner in the rubber industry, [Company Name] continues to set new benchmarks for excellence. The introduction of Rubber Flexible Bellows reinforces the company's commitment to innovation and customer satisfaction. By delivering a reliable and cost-effective solution, [Company Name] enables businesses to enhance their productivity, minimize downtime, and extend the lifespan of their machinery.In conclusion, Rubber Flexible Bellows offered by [Company Name] have revolutionized the industrial landscape. With exceptional durability, flexibility, and sealing properties, these bellows effectively protect machinery from damage caused by environmental factors. By absorbing various types of movement and providing efficient insulation, Rubber Flexible Bellows create a safer and more productive work environment. Through their dedication to quality and customization, [Company Name] continues to lead the way in delivering cutting-edge solutions for industrial applications.

The Importance of Expansion Bellows in Industrial Applications

Smith Corporation Introduces Innovative Expansion Bellows for Enhanced Industrial ApplicationsIndustrial manufacturing is an ever-evolving sector that demands continuous innovation to ensure smooth operations and optimal productivity. As the market leader in providing cutting-edge solutions, Smith Corporation has recently unveiled its latest product offering - Expansion Bellows. With an extensive track record of delivering quality equipment and exceptional customer service, Smith Corporation aims to revolutionize the industry by introducing these state-of-the-art Expansion Bellows.Smith Corporation, founded in 1990, is a renowned global manufacturer and supplier of industrial equipment. They have earned a reputation for their commitment to excellence, customer satisfaction, and continuous product development. With a dedicated team of engineers and researchers, the company is at the forefront of technological advancements, constantly striving to better serve their customers' needs.Expansion bellows, also known as expansion joints, play a critical role in industrial applications by compensating for thermal expansion, mechanical vibration, and other various movements. Being flexible connections, they absorb movement and stress, thus preventing damage to pipelines, ducts, and other equipment. Smith Corporation's Expansion Bellows are designed to withstand extreme temperatures, pressure differentials, and corrosive elements, guaranteeing reliability and longevity.One of the key features that set Smith Corporation's Expansion Bellows apart from the competition is their superior construction. These bellows are fabricated from high-quality materials such as stainless steel, carbon steel, or other alloys, ensuring exceptional durability and resistance to wear and tear. The bellows' unique design enables them to withstand immense pressure while maintaining their flexibility, thus prolonging their lifespan and reducing maintenance costs.Smith Corporation prides itself on its ability to customize their Expansion Bellows according to specific client requirements. The company's team of experts collaborates closely with customers to understand their needs and provide tailor-made solutions. Whether it's designing bellows for high-temperature applications or accommodating large movements in complex piping systems, Smith Corporation's engineers leverage their extensive knowledge to deliver optimal solutions.Furthermore, Smith Corporation's Expansion Bellows are rigorously tested and manufactured under stringent quality control measures. The company's state-of-the-art testing facilities ensure that each bellows unit adheres to the highest standards, meeting or surpassing industry regulations. Customers can have peace of mind, knowing they are investing in a reliable and safe product that surpasses their expectations.The applications for Smith Corporation's Expansion Bellows are widespread across several industries. These bellows find extensive usage in power plants, chemical processing plants, oil and gas refineries, HVAC systems, and many more. Their ability to absorb vibrations, accommodate thermal expansion, and minimize the risk of leakage makes them an essential component in various critical systems.Smith Corporation's commitment to sustainability is also reflected in its Expansion Bellows. The company ensures that its manufacturing processes follow environmentally friendly practices, minimizing waste generation and utilizing energy-efficient technologies. By choosing Smith Corporation's Expansion Bellows, customers not only benefit from high-performance equipment but also contribute to a greener future.In conclusion, Smith Corporation's latest offering - Expansion Bellows - represents a significant advancement in industrial equipment. With their exceptional durability, flexibility, and customization options, these bellows are poised to revolutionize the industry. As a global leader, Smith Corporation continues to push the boundaries of innovation, elevating standards and meeting the ever-evolving needs of its clients.

How to Prevent Pipe Damage from Thermal Expansion

As industries continue to evolve and expand, there is an increasing need for innovative solutions that can effectively address and solve problems faced during construction, maintenance, and production activities. One such solution that has been gaining increasing popularity in recent times is pipe thermal expansion. A method that concerns the force behind the expansion or contraction of materials through temperature fluctuations.One of the companies that have been leading the way in offering such innovative solutions is the renowned industry leader in manufacturing and installation of thermal expansion systems. Their technology not only delivers practical and efficient solutions but also helps to reduce operational costs, increase safety, and improve reliability.Thermal expansion happens when materials or structures expand or contract due to temperature fluctuations. For instance, when heated, a pipe expands and can either crack or leak if the expansion occurs beyond the pipe's capacity. This is where the thermal expansion system comes into play, its the ability to allow pipe expansion and contraction without undue stress, which ultimately saves the pipe from damages.The expansion of pipes is one of the significant issues that industries face in production. Thus, many companies have turned towards pipe thermal expansion solutions to increase the life span of their pipeline infrastructure systems. Construction, refinery, chemical, and other industries can benefit from the non-disruptive nature of the thermal expansion system offered by the company. The system ensures that the pipelines maintain their integrity and helps to prevent leaks and damages.Apart from reducing pipeline damages and disruptions, the thermal expansion technology also helps in the transportation of liquids through pipelines over long distances. The ability to expand or contract the pipes allows for the efficient delivery and transport of liquids and gaseous substances, which is vital in the modern industrial landscape.Additionally, the company's thermal expansion technology provides a suitable alternative to traditional pipeline insulation. Traditional insulation methods can increase energy consumption, and in turn, increase cost significantly. With pipe thermal expansion, pipes can expand and contract without undue stress while maintaining the required temperature, ultimately leading to a reduction in energy consumption.One of the significant benefits of the company's thermal expansion technology is its versatility. It is ideal for use in various pipeline infrastructure systems and applications such as underground piping, petroleum refineries, water treatment plants and many more. Additionally, the technology can function under a wide range of atmospheric and environmental conditions, thus making it an ideal solution for industries in various regions.In conclusion, the modern industrial landscape requires innovative solutions that can help to improve overall efficiency and productivity. The developmental efforts made by the company in the area of pipe thermal expansion have long term benefits, including increasing structural integrity, limiting unexpected downtime, increasing profitability, and protecting the environment. As industries continue to evolve at a rapid pace, the solution offered by the company is one of the critical drivers for industrial progress.

Revolutionary New Joint Technology Provides Unmatched Flexibility

Flexible Joint Revolutionizes the Industry with Innovative Engineering SolutionsIn today's rapidly evolving industrial landscape, improving the efficiency and performance of machinery and equipment has become paramount. As the demand for high-quality engineering solutions continues to rise, companies are constantly pushing boundaries to provide innovative products that enhance productivity in various industries. One such company that has been at the forefront of this revolution is an industry leader in providing cutting-edge flexible joint solutions (). With a keen focus on engineering excellence, they have revolutionized the industry by delivering state-of-the-art products that are designed to meet the evolving needs of their customers.Headquartered in (**City, Country**), the company has earned an enviable reputation for its commitment to innovation, reliability, and superior customer service. With a team of highly skilled engineers and technicians, they collaborate closely with clients to understand their unique requirements and tailor solutions to address specific challenges. Their relentless pursuit of technological advancements has set them apart from the competition, as they constantly strive to provide cutting-edge flexible joint solutions that exceed customer expectations.One of the company's flagship products is the innovative flexible joint, which has proven to be a game-changer in the industry. This versatile component plays a pivotal role in numerous applications, ranging from construction and manufacturing to aerospace and automotive sectors. The flexible joint effectively compensates for misalignments, vibrations, and thermal expansions, thereby minimizing stress on machinery and prolonging their lifespan. By allowing freedom of movement and absorbing shocks and loads, the flexible joint significantly enhances the overall performance and reliability of various types of equipment.What sets this flexible joint apart from traditional alternatives is its superior design and construction. Using advanced materials and state-of-the-art manufacturing processes, this flexible joint is not only highly durable but also offers exceptional resistance to corrosion and extreme temperatures. Its innovative design allows for easy installation and reduces maintenance time and costs. Additionally, with its smooth and silent operation, the flexible joint ensures a safe and comfortable working environment. These features make it an ideal choice for industries where precise alignment, smooth movement, and minimal downtime are crucial.The flexible joint has rapidly gained popularity among industrial giants, who have reported significant improvements in their operational efficiency and reduced maintenance costs after integrating these solutions into their machinery. The companies using the flexible joint have experienced reduced downtime, ensuring increased productivity and profitability. Its ability to reduce stress on machinery and dampen vibrations has resulted in improved equipment reliability, prolonging the lifespan of critical components. With its proven track record, the flexible joint has become an indispensable part of industrial machinery across a wide range of sectors.In addition to their world-class products, the company is dedicated to providing exceptional customer service. Their team of experts works closely with clients to understand their unique needs and challenges, offering customized solutions that meet specific requirements. The company's commitment to excellence goes beyond the sale of their products, as their technical support and after-sales service ensure clients receive ongoing assistance throughout the product lifecycle.Looking ahead, this industry leader continues to push the boundaries of engineering solutions. With ongoing investments in research, development, and technology, they aim to further enhance their product line and offer groundbreaking solutions to address emerging demands in the market. By combining customer feedback, market insights, and unparalleled engineering expertise, they are well-positioned to maintain their leadership in providing flexible joint solutions that drive industrial efficiency and productivity.In conclusion, the company has cemented its position as an industry leader by providing innovative flexible joint solutions. Their commitment to engineering excellence, customer satisfaction, and continuous improvement has revolutionized the industry, setting new standards for operational efficiency and reliability. With their game-changing products and exceptional customer service, this company is poised to remain at the forefront of the engineering solutions market, fueling progress and innovation for years to come.

Improve Your Piping System with NBR Twin Sphere Rubber Expansion Joints

NBR twin sphere rubber expansion joint is an essential component when it comes to piping systems. This type of expansion joint is made from high-quality NBR rubber that is designed to offer maximum flexibility. The rubber expansion joint has two spheres known as twin sphere, which are interconnected, and they can be used in different piping systems. Henan Shunying NBR twin sphere rubber expansion joint is one of the best in the market that offers excellent performance in terms of reducing noise and vibration, preventing damage, and extending the life of a piping system.The twin sphere rubber expansion joint is an important component in piping systems as it allows for the flow of fluids and gases while compensating for changes in pressure, temperature, and movement. The twin sphere design is more effective than a single sphere in reducing stress concentrations in the rubber, which helps to minimize the risk of failure and prolong the life of the joint.When selecting a twin sphere rubber expansion joint, it is essential to consider the quality of the material used in its construction. The NBR rubber used in the Henan Shunying twin sphere rubber expansion joint is a high-quality material that offers excellent resistance to abrasion, chemicals, and weathering. This ensures that the expansion joint remains durable, even in harsh environments.In addition to the quality of the material, it is also important to consider the design of the expansion joint. The Henan Shunying twin sphere rubber expansion joint is designed to provide maximum flexibility in the system. This flexibility allows it to compensate for changes in pressure and temperature, which helps to prevent damage to the piping system. The twin sphere design also helps to minimize noise and vibration, making it an ideal choice for applications where noise reduction is a concern.The installation of the Henan Shunying twin sphere rubber expansion joint is straightforward, and it comes with detailed instructions that are easy to follow. It is important to ensure that the expansion joint is installed properly to ensure optimal performance and durability.In conclusion, the Henan Shunying NBR twin sphere rubber expansion joint is an excellent choice for piping systems that require flexibility and durability. Its high-quality NBR rubber material and twin sphere design make it a reliable choice that can withstand harsh environments and provide maximum performance. When searching for an expansion joint for your piping system, be sure to consider the Henan Shunying twin sphere rubber expansion joint as a dependable option.

Suppliers of Compensators for Air Springs and Stainless Steel CNC Machining with Authentic Customer Reviews and Information

In the world of mechanical engineering, compensators are an essential component that plays a vital role in ensuring the smooth operation of various industrial processes. Compensators, in general, are used to compensate for thermal expansion or contraction, vibrations, and other mechanical stresses that may affect the overall performance of a given system.As such, the demand for high-quality compensators has risen over the years, with suppliers working tirelessly to ensure that they meet the growing needs of their customers. In response to this demand, the industry has seen a rise in the number of compensator suppliers, including those that specialize in air springs and stainless steel CNC machining.One such supplier is (brand name removed), which has been in the business of offering high-quality compensators to its customers for over a decade. The company's primary focus is on providing innovative solutions to customers, with a commitment to quality, reliability, and excellent customer service.One key area that the company has excelled in is providing air springs to its customers as a means of compensating for mechanical stress. Air springs are widely used in various industrial applications, including automotive, mining, and construction, to name a few. They offer a range of benefits, including stability, durability, and excellent load-carrying capacity.Another area where (brand name removed) has made remarkable strides is in stainless steel CNC machining. CNC machining is a computer-controlled process that involves the use of high-precision machines to manufacture complex parts and components. The process is highly accurate, with a level of precision that is hard to match using traditional machining methods.Stainless steel is a material that is widely used in various industrial applications due to its high strength, resistance to corrosion, and durability. As such, it is an ideal material for CNC machining, particularly for parts that require high precision and durability.The (brand name removed) team comprises highly skilled and experienced professionals who are committed to providing customers with the highest quality of products and services. The company uses the latest technology and techniques to manufacture its products, ensuring that they meet or exceed industry standards.In addition to providing high-quality air springs and CNC machining services, (brand name removed) also places a strong emphasis on customer service. The company believes that customer satisfaction is key to its continued success. As such, it goes the extra mile to ensure that its customers receive the best possible service, from initial contact through to post-sales support.The company's dedication to quality, innovation, and customer service has earned it an excellent reputation in the industry. Over the years, it has received numerous accolades and recognition for its outstanding products and services. It has also built strong relationships with its customers, many of whom have been with the company for years.In conclusion, the demand for high-quality compensators, including air springs and stainless steel CNC machining, continues to grow, with suppliers intensifying their efforts to meet the needs of their customers. (Brand name removed) is one such company that stands out in the industry, thanks to its commitment to quality, innovation, and customer service. With a team of highly skilled professionals and the latest technology, the company is well-positioned to continue providing its customers with the best possible products and services.