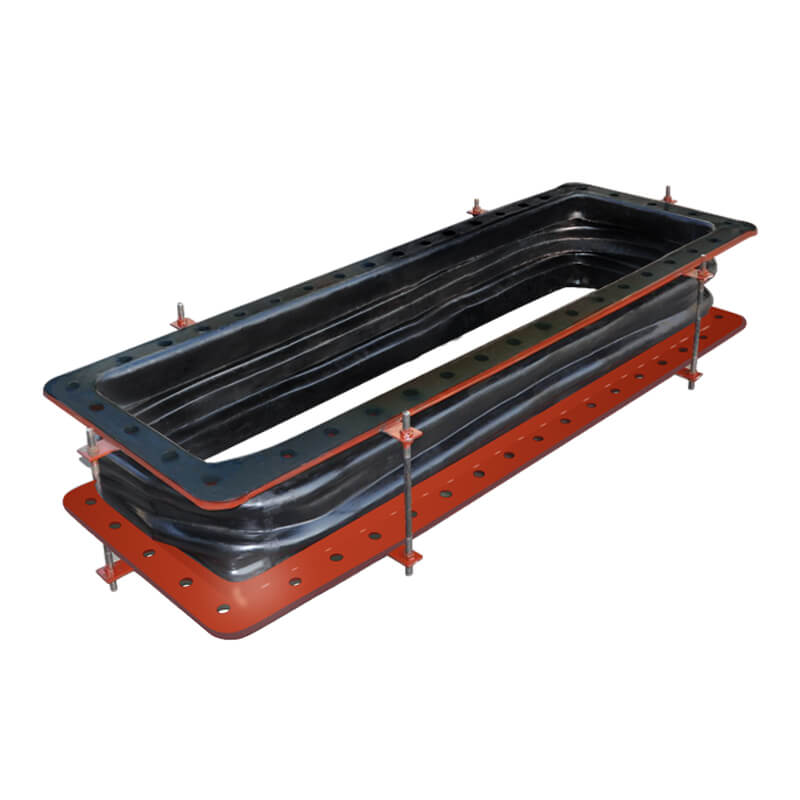

Rectangular Corrugated Compensator: An Innovative Solution for Flexible Pipe Expansion

By:Admin

Introduction:

[Company name] introduces its revolutionary Rectangular Corrugated Compensator, a breakthrough solution in addressing thermal expansion, vibration, and misalignment challenges in various industries. Designed with cutting-edge technology and employing advanced materials, this innovative compensator is set to redefine industry standards and provide unparalleled performance and reliability.

[Company name] is a leading industry player renowned for its commitment to research and development, engineering excellence, and customer-centric approach. With an extensive portfolio of groundbreaking products, the company continuously pushes the boundaries of technological advancements, enabling customers to enhance efficiency, minimize downtime, and optimize overall operations.

Groundbreaking Features of the Rectangular Corrugated Compensator:

The Rectangular Corrugated Compensator by [Company name] boasts several innovative features that set it apart from traditional compensators. These features include:

1. Enhanced Durability and Longevity: By utilizing high-quality materials and cutting-edge manufacturing techniques, this compensator is designed to withstand extreme temperatures, chemicals, and harsh environmental conditions. Its exceptional durability ensures prolonged service life, reducing maintenance costs and enhancing operational sustainability.

2. Optimal Thermal Expansion Compensation: The compensator effectively mitigates the potential risks associated with thermal expansion, allowing for seamless expansion and contraction of pipelines. This feature ensures the integrity and safety of piping systems, minimizing the likelihood of leaks, stress fractures, or catastrophic failures.

3. Superior Vibration and Noise Suppression: The Rectangular Corrugated Compensator considerably reduces vibration and noise caused by fluid flow, equipment movement, or pressure fluctuations. Its unique design employs precise corrugation patterns that absorb vibrations, thereby enhancing operational efficiency and providing a quieter and more comfortable working environment.

4. Versatility and Adaptability: With its flexible design, the compensator accommodates diverse pipe layouts, misalignments, and offsets, ensuring easy installation and seamless integration within existing systems. Its adaptability makes it a versatile solution for various industries, including petrochemicals, power generation, aerospace, and more.

Industry Impacts and Advantages:

The introduction of the Rectangular Corrugated Compensator presents numerous benefits across various industries, further anchoring [Company name]'s position as an industry leader. Some significant impacts include:

1. Enhanced Safety and Reliability: The compensator's ability to absorb thermal expansion and reduce vibration ensures the safe and reliable operation of pipelines, minimizing the risk of leaks, failures, and downtime. This feature is particularly critical in industries where safety is paramount.

2. Improved Operational Efficiency: By effectively addressing thermal expansion and vibration-related challenges, the compensator optimizes the overall performance of piping systems, improving efficiency and productivity. This translates into cost savings, reduced maintenance efforts, and increased operational profitability.

3. Easy Installation and Maintenance: The flexible and adaptable design of the compensator simplifies installation procedures, significantly reducing both time and labor requirements. Additionally, its durable construction minimizes the need for frequent inspections or replacements, resulting in reduced maintenance costs and minimal production disruptions.

4. Customization and Tailored Solutions: [Company name] prides itself on its ability to provide bespoke solutions that meet specific customer requirements. The Rectangular Corrugated Compensator can be customized in terms of size, materials, and performance parameters, ensuring optimal compatibility with diverse applications.

Conclusion:

The Rectangular Corrugated Compensator by [Company name] represents a groundbreaking advancement in addressing thermal expansion, vibration, and misalignment challenges across various industries. By providing enhanced safety, reliability, and operational efficiency, this innovative compensator establishes new industry standards while cementing [Company name]'s position as a trusted and innovative provider of high-performance solutions. The introduction of this revolutionary product is set to empower businesses to optimize their operations, minimize downtime, and achieve sustainable growth.

Company News & Blog

National Leader in Manufacturing Rubber Expansion Joints and Flex Products

Unisource Manufacturing Inc. is a well-known national leader in the manufacture of rubber expansion joints and a wide range of other flex products. The company has been providing its customers with high-quality, reliable products for over 50 years, and during that time, it has built a reputation for excellence that is second to none.One of the key products that Unisource specializes in is rubber expansion joints. These products are essential for maintaining the integrity of pipelines and other systems that rely on flexibility and durability to function properly. Specifically, rubber expansion joints allow for the movement and expansion of pipes, hoses, and other components without putting stress on the rest of the system. This helps to prevent leaks, cracks, and other damage that can lead to costly repairs and downtime.At Unisource, they understand that every customer's needs are different, which is why they offer a wide range of rubber expansion joint products to choose from. These products include spheres, spool-type joints, multiple arches, and high-pressure specs. All of these products are designed to provide superior performance, durability, and reliability, even in the most challenging environments.Unisource's rubber expansion joints are made from the highest-quality materials, including natural rubber, EPDM, neoprene, and Viton. Each product is thoroughly tested and inspected to ensure that it meets or exceeds the company's high standards for quality and reliability. This attention to detail and commitment to excellence is what sets Unisource apart from the competition.In addition to rubber expansion joints, Unisource also offers a wide range of other products, including metal hoses, industrial hoses, and hydraulic hoses. Each of these products is designed to meet the specific needs of its customers, with the same high standards of quality and performance that customers have come to expect from Unisource.Unisource's commitment to customer satisfaction doesn't end with the quality of its products. The company also provides exceptional customer service, with a team of knowledgeable and experienced professionals who are dedicated to helping customers find the right products for their needs. Whether customers need assistance with product selection, installation, or troubleshooting, the Unisource team is always there to help.In summary, Unisource Manufacturing Inc. is a national leader in the manufacture of rubber expansion joints and other flex products. With over 50 years of experience, the company has built a reputation for excellence that is second to none. Its products are designed to provide superior performance, durability, and reliability, even in the most challenging environments. And with a commitment to customer satisfaction that extends beyond the quality of its products, Unisource is the clear choice for those seeking a partner they can trust.

Neoprene Used for Concrete, Soybean Sealer, Expansion Joint and Polyethylene Foam: Specifications provided

article on the benefits and applications of Neoprene in construction and engineering industries.Neoprene | Concrete Soybean Sealer, Expansion Joint, Polyethylene foamNeoprene is a versatile synthetic rubber that has been used in numerous applications ranging from wetsuits to electrical insulation. The material was first developed in the 1930s by DuPont and quickly gained popularity for its unique properties, including the ability to withstand exposure to oils, chemicals, and extreme temperatures.Today, Neoprene has found its way into various construction and engineering industries as a reliable and effective material for sealing, cushioning, and protecting buildings and structures. One manufacturer that has been at the forefront of Neoprene applications is C2 Products, Inc. However, the company has requested the removal of its brand name from this article.C2 Products, Inc. has been a leading manufacturer of Neoprene-based products for over 30 years. During this time, the company has developed an array of specialized materials that cater to the unique needs of construction and engineering projects. Some of their most popular products include Concrete Soybean sealer, Expansion Joint, and Polyethylene foam.One of the primary benefits of Neoprene in construction is its excellent weatherability properties. The material can withstand exposure to harsh outdoor elements such as UV rays, wind, and rain without breaking down or deteriorating. Additionally, Neoprene has insulation properties that can help regulate temperature, making it an ideal material for roofing and flooring applications.Another significant advantage of Neoprene is its ability to resist oil, grease, and other chemical solvents. This characteristic makes Neoprene an ideal material for sealing and cushioning joints and connections in industrial facilities.One of the most popular Neoprene-based products produced by C2 Products, Inc. is the Concrete Soybean sealer. This product is designed to penetrate the surface of concrete and form a protective barrier against water, salts, and other contaminants. Additionally, the Concrete Soybean sealer is an environmentally friendly alternative to traditional concrete sealers, as it is made from renewable soybeans.Expansion Joints are another critical application for Neoprene in construction. These joints are designed to protect buildings and structures from the damaging effects of thermal expansion and contraction. Neoprene-based Expansion Joints are ideal as they can withstand extreme temperature fluctuations without breaking down or deteriorating.Polyethylene foam is another popular Neoprene-based product that is widely used in the construction industry. This material is known for its excellent shock absorption properties, making it an ideal choice for cushioning and protecting fragile components during transportation and installation. Additionally, Polyethylene foam can be found in a variety of insulation applications and is widely used in building and HVAC systems.In conclusion, Neoprene is a versatile material that has become an essential component in a range of construction and engineering applications. Its unique properties make it an ideal material for sealing, cushioning, and protecting buildings and structures. Whether it's the Concrete Soybean sealer, Expansion Joints, or Polyethylene foam, Neoprene-based products have become a vital component in the construction industry, ensuring that buildings and structures are protected for years to come.

Ultimate Guide: Optimizing Metallic Bellows Designs for Enhanced Performance

Metallic Bellows Design: A Revolution in Industrial EngineeringIn the world of industrial engineering, companies are constantly striving to develop innovative solutions that improve the efficiency and reliability of complex systems. One such breakthrough comes in the form of metallic bellows design, a revolutionary technology that promises to redefine the way industries operate. This cutting-edge design, developed by an industry-leading company, has already garnered significant attention and is set to transform various sectors worldwide.This groundbreaking metallic bellows design, pioneered by [Company Name], represents a significant leap forward in the field of industrial engineering. By incorporating state-of-the-art materials and engineering principles, these bellows are capable of withstanding extreme conditions while providing unparalleled performance and longevity.[Company Name], a trailblazer in the engineering industry, has a formidable reputation for continually pushing boundaries and spearheading innovation. With decades of experience in designing and manufacturing high-quality industrial systems, the company is now revolutionizing the way industries function with its metallic bellows design.Traditionally, bellows, typically made of rubber or fabric, have been used to compensate for thermal expansion, vibrations, and other stresses in industrial systems. However, these conventional bellows often fall short when it comes to durability and performance. With the advent of metallic bellows design, these limitations are effectively addressed.The key advantage of metallic bellows design lies in its unique composition. Constructed using advanced alloys and precision manufacturing processes, these bellows are incredibly robust and resistant to extreme temperatures, pressure differentials, and corrosive environments. This inherent durability ensures that industrial systems can run smoothly and efficiently, even in the harshest conditions.Moreover, the design of metallic bellows enables them to compensate for complex movements and vibrations with exceptional accuracy. This flexibility, combined with the ability to absorb stress, guarantees the longevity of critical components within industrial systems. Consequently, businesses can experience reduced maintenance costs, minimal downtime, and enhanced operational efficiency, leading to improved productivity and profitability.[Company Name]'s metallic bellows design has applications across various industries, including oil and gas, aerospace, automotive, and petrochemicals, to name a few. For instance, in the oil and gas sector, where equipment is subjected to extreme pressures and temperatures, these bellows offer a reliable solution for compensating thermal expansion in pipelines and valves. In the aerospace industry, metallic bellows find applications in aircraft engines, where they effectively absorb vibrations and compensate for thermal stresses.Recognizing the immense potential of this revolutionary design, [Company Name] is investing significantly in research and development. By partnering with leading research institutions and collaborating with industry experts, the company strives to constantly improve and expand the capabilities of metallic bellows design.Furthermore, [Company Name] places immense emphasis on quality and adherence to international standards. Manufacturing facilities are equipped with state-of-the-art technology and operated by highly skilled technicians. Rigorous quality control measures are in place to ensure that every metallic bellows produced meets the most demanding specifications, providing customers with products of unrivaled reliability and performance.In conclusion, metallic bellows design is a game-changer in the world of industrial engineering. [Company Name]'s pioneering work in this field is set to transform various sectors, offering unparalleled reliability, durability, and performance. As industries continue to evolve and demand more sophisticated solutions, metallic bellows design will undoubtedly play a pivotal role in shaping the future of industrial systems.

Discover the Latest Updates on Expansion Joints: Key Developments Unveiled!

Possible news article:New Expansion Joint Products Unveiled by Leading ManufacturerA leading manufacturer of engineering products has launched a new series of Expansion Joint (EJ) solutions, designed to meet the needs of a wide range of industries and applications. The company has combined its expertise in materials science, mechanical engineering, and software design to create four new models of EJ that offer improved performance, reliability, and cost-effectiveness for customers worldwide.The new products, which are available in various sizes, shapes, and materials, are designed to reduce the stress and strain on pipes, tanks, vessels, and other structures that are subject to thermal changes, vibrations, or movements. The EJ components are made of high-quality elastomers, metals, or composites that can withstand extreme temperatures, pressures, and environmental conditions, while providing flexibility, expansion, and contraction capabilities that can prevent leaks, cracks, or failures.The first EJ model, called "FlexiJoint", is a rubber expansion joint that can handle up to 10 bar pressure and temperatures ranging from -40°C to +120°C. It is suitable for water, wastewater, chemical, and other liquids transportation systems that require flexibility and noise reduction. The FlexiJoint has a smooth interior surface that reduces turbulence and sedimentation, and a flanged or threaded connection that simplifies installation and maintenance.The second EJ model, named "MetallicJoint", is a metal expansion joint that can withstand up to 100 bar pressure and temperatures ranging from -200°C to +800°C. It is ideal for high-temperature, high-pressure, and corrosive industrial processes that require tight sealing, stability, and durability. The MetallicJoint has multiple bellows that absorb axial, lateral, and angular movements, as well as tie rods that provide additional support and stiffness. It also has a wide range of end connections, including flanges, weld ends, and threaded ends.The third EJ model, known as "CompositeJoint", is a composite expansion joint that combines the advantages of rubber and metal materials, such as flexibility and strength. It can handle up to 40 bar pressure and temperatures ranging from -50°C to +150°C. It is suitable for marine, offshore, and shipbuilding applications that require resistance to seawater, UV, and fire. The CompositeJoint has a unique design that incorporates rubber pads, metal inserts, and fiberglass layers that can absorb vibrations, shocks, and noise. It also has a lightweight and compact structure that reduces the weight and space requirements of the system.The fourth EJ model, called "FabricJoint", is a fabric expansion joint that can handle up to 5 bar pressure and temperatures ranging from -20°C to +200°C. It is suitable for HVAC, power, and air pollution control systems that require flexibility and airtightness. The FabricJoint has a fabric cover that can resist abrasion, chemicals, and high-velocity gas streams, as well as a metal frame that can maintain its shape and sealing performance. It also has a variety of flange or pipe connections that can fit different duct or pipe sizes and configurations.According to the company spokesperson, the new EJ series represents a significant improvement over previous products, in terms of performance, reliability, and customization options. "We have listened to our customers' feedback and analyzed the market trends and challenges, and we have optimized our EJ designs to meet their evolving needs," said the spokesperson. "We have also invested in cutting-edge machinery and software tools that enable us to produce EJ components with high precision and speed, and to test them rigorously for quality assurance."The spokesperson also highlighted the company's commitment to sustainability and social responsibility, by using eco-friendly and ethical materials and practices, as well as supporting local communities and charities. "We believe that engineering excellence and social impact are two sides of the same coin, and we strive to achieve both in every aspect of our business," said the spokesperson. "We also offer our customers expert technical advice, training, and maintenance services, to ensure that their EJ systems perform optimally and safely throughout their lifespan."The new EJ products are now available for orders and deliveries worldwide, either directly from the company or from its authorized distributors and partners. Customers can also request customized solutions that meet their specific requirements and preferences, such as special materials, coatings, colors, or certifications.In conclusion, the new Expansion Joint series of the leading manufacturer is a testament to its innovation, quality, and customer-centric approach, and is expected to enhance the efficiency, safety, and sustainability of various industries and applications.

How to Prevent Pipe Damage from Thermal Expansion

As industries continue to evolve and expand, there is an increasing need for innovative solutions that can effectively address and solve problems faced during construction, maintenance, and production activities. One such solution that has been gaining increasing popularity in recent times is pipe thermal expansion. A method that concerns the force behind the expansion or contraction of materials through temperature fluctuations.One of the companies that have been leading the way in offering such innovative solutions is the renowned industry leader in manufacturing and installation of thermal expansion systems. Their technology not only delivers practical and efficient solutions but also helps to reduce operational costs, increase safety, and improve reliability.Thermal expansion happens when materials or structures expand or contract due to temperature fluctuations. For instance, when heated, a pipe expands and can either crack or leak if the expansion occurs beyond the pipe's capacity. This is where the thermal expansion system comes into play, its the ability to allow pipe expansion and contraction without undue stress, which ultimately saves the pipe from damages.The expansion of pipes is one of the significant issues that industries face in production. Thus, many companies have turned towards pipe thermal expansion solutions to increase the life span of their pipeline infrastructure systems. Construction, refinery, chemical, and other industries can benefit from the non-disruptive nature of the thermal expansion system offered by the company. The system ensures that the pipelines maintain their integrity and helps to prevent leaks and damages.Apart from reducing pipeline damages and disruptions, the thermal expansion technology also helps in the transportation of liquids through pipelines over long distances. The ability to expand or contract the pipes allows for the efficient delivery and transport of liquids and gaseous substances, which is vital in the modern industrial landscape.Additionally, the company's thermal expansion technology provides a suitable alternative to traditional pipeline insulation. Traditional insulation methods can increase energy consumption, and in turn, increase cost significantly. With pipe thermal expansion, pipes can expand and contract without undue stress while maintaining the required temperature, ultimately leading to a reduction in energy consumption.One of the significant benefits of the company's thermal expansion technology is its versatility. It is ideal for use in various pipeline infrastructure systems and applications such as underground piping, petroleum refineries, water treatment plants and many more. Additionally, the technology can function under a wide range of atmospheric and environmental conditions, thus making it an ideal solution for industries in various regions.In conclusion, the modern industrial landscape requires innovative solutions that can help to improve overall efficiency and productivity. The developmental efforts made by the company in the area of pipe thermal expansion have long term benefits, including increasing structural integrity, limiting unexpected downtime, increasing profitability, and protecting the environment. As industries continue to evolve at a rapid pace, the solution offered by the company is one of the critical drivers for industrial progress.

Effective Solutions for Rubber Expansion Joints with Threaded Unions

Title: Innovative Threaded Union Rubber Expansion Joint Sets New Standards in Industrial Piping Solutions Introduction (100 words):In the constantly evolving field of industrial piping solutions, a pioneering company has emerged with a groundbreaking product that is revolutionizing the industry. Threaded Union Rubber Expansion Joint, developed by an industry-leading company, offers an innovative and efficient solution for pipe connection applications. Boasting exceptional performance, flexibility, and durability, this expansion joint is set to redefine the market, providing engineers and professionals across a wide range of sectors with a reliable and high-quality solution.Body:1. The Importance of Robust Pipe Connections (150 words):Ensuring reliable and leak-free pipe connections is crucial for industrial applications. Piping systems are used extensively across industries such as chemical, petrochemical, oil and gas, wastewater treatment, power generation, and HVAC. Failure in these systems can lead to significant operational disruptions, financial losses, and even safety hazards. Hence, industry professionals constantly seek better solutions to enhance the stability, flexibility, and longevity of their pipe connections.2. Introducing Threaded Union Rubber Expansion Joint (150 words):Threaded Union Rubber Expansion Joint is an advanced product that addresses the challenges faced by industrial piping systems. Built on cutting-edge technology, this expansion joint is designed to provide exceptional performance and reliability in demanding environments. The joint combines rubber and metal components to form a flexible connection that can absorb vibrations, compensate for thermal expansion, and reduce noise.3. Key Features and Benefits (200 words):a. Versatility: Threaded Union Rubber Expansion Joint caters to different pipe materials, diameters, and working pressures. It can be adapted to various installation requirements, making it suitable for a wide range of industrial applications.b. Flexibility: The joint's elastomeric construction allows it to absorb movement and stress, compensating for thermal expansion, contraction, and misalignment. This flexibility minimizes the risk of pipe failure and reduces fatigue on the system, extending the lifespan of the overall piping network.c. Enhanced Durability: The joint's robust design ensures resilience to harsh operating conditions, such as exposure to chemicals, high temperatures, and corrosive substances. This makes it ideal for industries that demand long-lasting and reliable performance.d. Noise and Vibration Reduction: The joint significantly reduces the transmission of noise and vibrations, enhancing safety and creating a quieter working environment.e. Easy Installation and Maintenance: Threaded Union Rubber Expansion Joint features a user-friendly design that simplifies installation, with reduced downtime and no special tools required. Routine maintenance is straightforward, ensuring hassle-free upkeep of the piping system.4. Market Impact and Future Prospects (150 words):The introduction of Threaded Union Rubber Expansion Joint is poised to create a significant impact on the market for industrial piping solutions. With its superior capabilities, the joint can enhance the operational efficiency, reliability, and safety of a wide range of industries. The product's potential to reduce downtime, minimize maintenance costs, and extend the service life of the piping system makes it an appealing choice for engineers and professionals.Looking ahead, this innovative expansion joint is expected to contribute to the ongoing development of high-performance piping systems, offering a sustainable and cost-effective solution. In a rapidly growing industrial landscape, where reliability and robustness are essential, Threaded Union Rubber Expansion Joint sets a new benchmark for the industry, ensuring seamless pipe connections that are built to withstand the most challenging conditions.Conclusion (100 words):Threaded Union Rubber Expansion Joint offers an innovative solution for industrial piping systems, providing a combination of exceptional performance, versatility, and reliability. With its ability to absorb stress, reduce noise and vibrations, and resist the harshest operating conditions, this expansion joint is set to redefine the industry standards. As professionals across various industrial sectors demand reliable and robust piping solutions, the Threaded Union Rubber Expansion Joint emerges as a game-changer, revolutionizing the way we approach pipe connections.

Understanding the Importance of Expansion Joints in Construction

Title: Industry Leader Unveils Groundbreaking 8 Expansion Joint - Revolutionizing Infrastructure SolutionsIntroduction:In the fast-paced world of infrastructure development, companies constantly strive to deliver innovative solutions that improve efficiency, durability, and safety. Today, we are thrilled to introduce a game-changing product in the field of expansion joints. Developed by a leading company renowned for its exceptional engineering prowess, the 8 Expansion Joint aims to cater to the evolving needs of the construction industry. Offering enhanced functionality, unparalleled quality, and groundbreaking design, this revolutionary product is set to redefine the way infrastructural projects are executed and maintained.Product Overview:The 8 Expansion Joint, developed by cutting-edge engineering company X, is a groundbreaking creation that seeks to address the limitations of conventional expansion joints utilized in bridges, highways, and various other infrastructure projects. This highly advanced joint system provides unmatched flexibility, durability, and functionality, which is essential for ensuring the seamless operation of structures subjected to dynamic forces.Unparalleled Flexibility:The primary distinguishing feature of the 8 Expansion Joint lies in its extraordinary flexibility. Traditional expansion joints often struggle to accommodate the expansion and contraction of interconnected structures, leading to cracks, compromises in safety, and frequent maintenance requirements. However, the 8 Expansion Joint's innovative design allows it to absorb and dissipate movement stresses, ensuring the integrity of the overall structure. By seamlessly flexing and adapting to dynamic forces, this solution guarantees longevity and safety, thereby minimizing the need for regular repairs and replacements.Enhanced Durability:The 8 Expansion Joint outperforms conventional products in terms of durability, guaranteeing longevity and reliability. Its unique design incorporates state-of-the-art materials that withstand harsh environmental conditions, including extreme temperatures, heavy traffic loads, and corrosive elements. These materials, combined with rigorous testing, ensure that the joint system remains intact, maintaining structural integrity over extended periods. By significantly reducing the occurrence of cracks and deteriorations, this breakthrough technology reduces maintenance costs and optimizes the lifespan of infrastructural projects.Revolutionary Design:In addition to exceptional flexibility and durability, the 8 Expansion Joint boasts a revolutionary design that simplifies installation and maintenance processes. Unlike traditional joints that require extensive labor and time-consuming processes, this innovative solution offers easy installation and minimal disruption to ongoing construction projects. Additionally, periodic inspections and maintenance routines can be accomplished with ease, saving time and resources. The joint's intuitive design also contributes to cost-effectiveness, allowing infrastructure developers to allocate their budgets more efficiently while ensuring high-quality results.Company Background:X, the pioneering company behind the 8 Expansion Joint, is an industry leader renowned for its cutting-edge engineering solutions since its establishment in XXXX. With an unwavering commitment to excellence and a deep understanding of the evolving needs of the construction industry, X has successfully transformed the way infrastructural projects are executed worldwide. The company's team of experienced engineers and researchers consistently push boundaries to develop revolutionary products that exceed industry standards and revolutionize the field.Conclusion:As the construction industry evolves, innovative solutions become crucial for meeting the increasing demand for robust and long-lasting infrastructure. The introduction of the 8 Expansion Joint by X represents a milestone in the world of expansion joints, offering unmatched flexibility, durability, and functionality. Developed by a company dedicated to engineering excellence, this revolutionary product promises to transform the construction landscape. With its revolutionary design and exceptional performance, the 8 Expansion Joint is set to redefine industry standards, providing developers with increased efficiency, extended lifespan, and reduced maintenance costs.

Blast Furnace Tuyeres and Stocks: Essential Components for Iron Production

Blast Furnace Tuyeres and Tuyere Stocks: The Importance of Metal CompensatorsThe blast furnace (BF) is an essential piece of equipment in the production of iron and steel. Its objective is to extract hot metal from a mixture of iron ore, coke, and fuel. One critical component of the BF is the tuyere— the opening through which hot air is injected into the furnace. To ensure the smooth operation of the BF and prevent costly downtime, it is crucial to use high-quality tuyeres that can withstand the high temperatures and pressures of the hot blast air.One important component that plays a critical role in the tuyere assembly is the metal compensator. Metal compensators are flexible, metallic bellows that are used to accommodate the thermal expansion and contraction of the tuyere stock. As the temperature inside the BF increases, the tuyere stock expands, which can cause stress and damage to the surrounding components. Metal compensators are designed to absorb these stresses by flexing and contracting with the tuyere stock, thus protecting the tuyere from damage.In addition to protecting the tuyere from damage, metal compensators provide other critical benefits to the BF process. For example, they help to reduce the overall stress on the tuyere stock, which can improve the lifespan of the tuyere assembly. They can also help to control the flow of hot air into the BF, which can improve the efficiency and accuracy of the process.When selecting a metal compensator for use in a BF tuyere assembly, several factors must be considered. For example, the compensator's material must be able to withstand the high temperatures and pressures of the hot blast air. The design of the compensator must also be carefully considered to ensure that it can withstand the stresses of the tuyere assembly.Metal compensators used in BF tuyere assemblies are often made from materials such as stainless steel or high-temperature alloys, such as Inconel. These materials are highly resistant to thermal stress and corrosion, and they offer excellent flexibility and durability. They can also be designed to accommodate a range of movement and expansion, making them highly versatile and suitable for a range of different tuyere applications.In conclusion, metal compensators play a vital role in the successful operation of a blast furnace tuyere assembly. They help to protect the tuyere from damage, improve efficiency and accuracy, and extend the life of the tuyere assembly. When selecting a metal compensator for use in a BF tuyere assembly, it is essential to consider factors such as the material, design, and performance characteristics. By carefully selecting the right metal compensator, operators can help to ensure the smooth and efficient operation of the BF process.

Rubber Expansion Bellows Dimensions: Choosing the Right Fit for Your ApplicationWhen it comes to ensuring the safe and efficient operation of pipelines and machinery, rubber expansion joints and bellows play a crucial role. These flexible elements help compensate for movements, absorb vibrations, and reduce noise, ultimately protecting equipment and extending its lifespan. As premier suppliers of rubber expansion joints in the UAE, we understand the diverse needs of our clients and provide a wide range of options to meet those needs.One of the critical factors to consider while selecting rubber expansion joints or bellows is their dimensions. Accurate dimensioning ensures a proper fit, preventing leaks, pressure imbalances, and potential damages to the system. In this blog, we will explore the importance of rubber expansion bellows' dimensions and ways to choose the right fit for your application.Understanding Rubber Expansion Bellows DimensionsRubber expansion bellows are designed to accommodate various movements caused by thermal expansion, vibrations, pressure changes, or misalignments between pipes and equipment. The dimensions of expansion bellows play a significant role in determining their performance and ability to withstand these movements.Diameter:The outer and inner diameters of rubber expansion bellows directly impact their functionality. The outer diameter should match the respective pipe size, ensuring proper alignment and connection. On the other hand, the inner diameter determines the flow capacity of the system. It is crucial to select an expansion bellows with an inner diameter that matches the flow requirements of your specific application.Length:The length of rubber expansion bellows refers to the distance between the flange faces when the bellows is fully extended or compressed. This dimension is crucial to ensure the bellows' ability to absorb movements without overstressing or compressing beyond its designed limits. Determining the correct length is crucial to maintain the overall integrity and performance of the system.Movement Capability:The movement capability of rubber expansion bellows is closely linked to their dimensions. It is essential to consider the anticipated axial, lateral, and angular movements that the bellows will experience in your application. These movements may arise from changes in temperature, pressure, or vibrations. Choosing bellows with appropriate dimensions and movement capabilities ensures the desired flexibility and durability of the system.Thickness:The thickness of rubber expansion bellows determines their resilience and resistance to pressure and external forces. Thick-walled bellows provide better resistance to external impacts but may reduce their flexibility. Conversely, thin-walled bellows may provide increased flexibility but may compromise their long-term durability. Selecting the right thickness requires careful consideration of the specific operating conditions and the required balance between flexibility and durability.Pressure Ratings:The dimensions of rubber expansion bellows also contribute to their pressure ratings. Components of different dimensions, such as wall thickness and bellows length, have varying pressure resistance capabilities. It is essential to choose bellows with appropriate pressure ratings to ensure safe and efficient operation within your system.Choosing the Right Rubber Expansion Bellows DimensionsTo ensure optimal performance and reliability, consider the following factors when selecting rubber expansion bellows dimensions for your application:1. Understand the application requirements and operating conditions, including temperature fluctuations, pressure variations, and the types of movements the bellows needs to accommodate.2. Consult with experts in the field, such as our knowledgeable team, who can guide you in selecting the appropriate dimensions based on your specific needs.3. Evaluate the compatibility of the selected dimensions with your existing system components, ensuring a proper fit and connection.4. Regularly inspect and assess the performance of the rubber expansion bellows over time to ensure they continue to meet the system's needs adequately.ConclusionRubber expansion bellows are essential components in numerous industrial applications, providing flexibility and protection to pipelines and machinery. By carefully considering dimensions, such as diameter, length, movement capability, thickness, and pressure ratings, you can select the right rubber expansion bellows for your specific application.As the premier supplier of expansion joints in the UAE, we offer an extensive range of rubber expansion bellows, utilizing our expertise to ensure the perfect fit for your system. Contact us today to explore our extensive selection and benefit from our knowledgeable team's advice for optimal performance and longevity of your system.

Top 5 Rubber Joint Tips: Essential Insights for Better Joint Health

Title: Advanced Rubber Joint Technology Revolutionizes Industry ApplicationsIntroduction:In an era where innovation and efficiency are crucial to stay competitive, companies around the world are constantly seeking breakthrough technologies that can revolutionize their respective industries. One such technology making waves in the market is the advanced rubber joint, a versatile and reliable product that offers numerous applications across various sectors. Combining superior engineering with durability, these rubber joints provide enhanced performance and longevity, raising the bar for industry standards and redefining the possibilities for countless sectors worldwide.Rubber Joint: A Multifaceted Solution for Diverse IndustriesRubber joints, also known as expansion joints, serve as flexible connectors designed to absorb movement in pipes, tanks, and fittings, thus preventing damage and reducing stress on the overall system. The upgraded rubber joint technology, pioneered by one of the leading innovators in this field, has gained significant traction due to its outstanding features and unmatched quality.Manufactured using premium-grade rubber compounds, these joints offer exceptional resistance to temperature, pressure, and chemical corrosion, making them ideal for applications in sectors ranging from oil and gas to construction and manufacturing. With their ability to handle displacement, vibrations, and misalignment, rubber joints provide enhanced reliability and durability, ensuring smooth and efficient operations even in demanding environments.Revolutionizing Industry Applications1. Oil and Gas Sector:Rubber joints find extensive applications in the oil and gas industry, where they help to absorb vibrations and shocks caused by the flow of petroleum products, minimizing the risk of pipeline damage or leaks. By effectively accommodating thermal expansions and contractions, these joints improve the overall safety and reliability of the pipeline network.2. Construction Sector:In the construction industry, rubber joints play a critical role in absorbing structural movements caused by seismic activities, wind, or ground settlement. By allowing controlled movement, these joints prevent cracks and damages to buildings, offering cost-effective and long-lasting solutions for architects and construction engineers.3. Manufacturing Sector:Rubber joints play a vital role in manufacturing facilities by absorbing vibrations and reducing noise levels generated by heavy machinery. By minimizing the impact of these factors, rubber joints contribute to a safer working environment while improving the overall operational efficiency.4. Water Treatment Sector:In water treatment plants, rubber joints are widely used to compensate for thermal expansion and contraction in pipelines. By allowing for controlled movement, these joints prevent damage and leakage, ensuring uninterrupted water supply and reducing operational costs associated with maintenance and repairs.Leading the Industry with Innovative SolutionsThe company behind this revolutionary rubber joint technology has firmly established itself as a leader in the field. With a strong commitment to research and development, they consistently strive to deliver cutting-edge solutions that cater to the evolving needs of diverse industries. By leveraging advanced manufacturing techniques, rigorous quality control, and a customer-centric approach, they have built a reputation for excellence.Moreover, the company's dedication to sustainability is evident through its commitment to using eco-friendly materials and processes in the production of rubber joints. By prioritizing environmental consciousness, they ensure their products not only meet industry standards but also contribute to a greener future.Conclusion:The advanced rubber joint technology has emerged as a game-changer in various industries, offering unmatched flexibility, durability, and reliability. Their applications in the oil and gas, construction, manufacturing, and water treatment sectors have led to safer operations, reduced maintenance costs, and improved overall efficiency. With the company's commitment to innovation and sustainability, the future of the rubber joint industry looks promising, setting new benchmarks for quality and performance.