Innovative Double Sphere Flex Connector for Improved Efficiency

By:Admin

In the ever-evolving world of engineering and manufacturing, innovations are constantly being developed to improve the efficiency and reliability of various products and systems. One such innovation that has been making waves in the industry is the Double Sphere Flex Connector, a game-changing solution that is revolutionizing the way connections are made in a wide range of applications.

The Double Sphere Flex Connector, produced by an industry-leading company specializing in the design and manufacturing of high-quality fluid control products, is a versatile and durable component that offers a number of unique advantages over traditional connector solutions. To better understand the impact and significance of this groundbreaking product, it’s important to take a closer look at the company behind it.

{Company}, a global leader in fluid control technology, has been at the forefront of the industry for over three decades. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for a wide range of customers in various sectors, including automotive, aerospace, energy, and more. With a commitment to research and development, {Company} has consistently delivered cutting-edge solutions that have set new industry standards and redefined best practices.

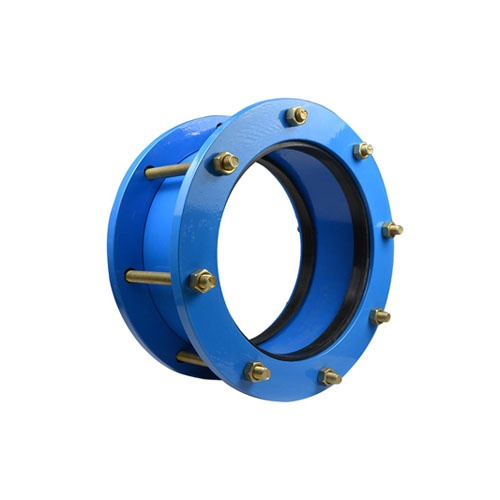

The Double Sphere Flex Connector is a perfect example of {Company}’s commitment to innovation and excellence. Designed to accommodate movement, absorb noise and vibration, and compensate for misalignment, this revolutionary connector offers unparalleled flexibility and reliability. Its unique double-sphere design allows for greater range of motion and adaptability, making it ideal for applications where traditional connectors may fall short.

One of the key benefits of the Double Sphere Flex Connector is its ability to reduce stress and damage to connected components, thereby extending the lifespan of the entire system. This can result in significant cost savings for customers in terms of maintenance and replacement expenses. Additionally, the increased flexibility of the connector can help improve overall system performance, reliability, and safety, making it a valuable asset in critical applications where failure is not an option.

Furthermore, the Double Sphere Flex Connector is designed to meet the highest industry standards for quality and performance. Manufactured with precision engineering and using the finest materials, it is built to withstand the most demanding operating conditions, including extreme temperatures, pressure differentials, and corrosive environments. With a focus on durability and longevity, {Company} has once again demonstrated its unwavering dedication to delivering products that exceed customer expectations.

In addition to its technical advantages, the Double Sphere Flex Connector is also designed for ease of installation and maintenance, helping to reduce downtime and labor costs. Its user-friendly design and compatibility with a wide range of pipe and tubing systems make it a versatile solution for various applications, from industrial machinery to infrastructure projects.

The introduction of the Double Sphere Flex Connector represents a significant milestone for {Company} and the industry as a whole. By leveraging their expertise and experience, the company has once again raised the bar for what is possible in fluid control technology, and set a new standard for innovation and performance.

As the demand for reliable, efficient, and durable connector solutions continues to grow across various industries, the Double Sphere Flex Connector is poised to become a go-to choice for engineers, designers, and end-users looking to optimize their systems and operations. With its unmatched combination of flexibility, reliability, and quality, this groundbreaking product is set to make a lasting impact on the industry for years to come.

In conclusion, the Double Sphere Flex Connector is a true game-changer, offering a level of performance and versatility that is unmatched by traditional connector solutions. With the backing of a reputable and innovative company like {Company}, this revolutionary product is poised to make a lasting impact on the industry, and set new standards for excellence and reliability.

Company News & Blog

The Advantages of Bellows Type Expansion Joints for Your Industrial Applications

A leading manufacturer of Bellows Type Expansion Joints (brand name removed) has recently been making headlines for its innovative approach to the design and production of these important industrial components. With a long history of expertise in the field, this company has built a reputation for excellence and reliability, providing essential solutions to a wide variety of industries and applications.One of the key factors behind the company's success is its commitment to research and development. By constantly exploring new materials, techniques, and applications, this manufacturer has been able to continuously improve the quality of its products, making them more durable, efficient, and cost-effective than ever before. This dedication to innovation has also allowed the company to expand its offerings, providing custom solutions for unique and challenging requirements.Another strength of this manufacturer is its focus on customer service. With a team of highly skilled and knowledgeable professionals, the company is able to provide expert support through every stage of the purchasing process. Whether it's helping clients to choose the right expansion joint for their needs, tracking delivery status, or providing advice on installation and maintenance, the team is always available to offer helpful insights and assistance.Of course, the real proof of a product's quality is in its performance, and that's where this manufacturer really stands out. With a wide range of sizes, materials, and configurations available, these Bellows Type Expansion Joints can handle even the most demanding applications. From high-temperature environments to corrosive chemical processing, these components provide reliable performance and long service life, greatly reducing downtime and maintenance costs for customers.Beyond these practical benefits, there are also significant environmental advantages to be gained from incorporating Bellows Type Expansion Joints into industrial systems. By accommodating the thermal expansion and contraction that occurs in piping networks, these components help to prevent stress, leaks, and other damage that can lead to hazardous spills or emissions. They also help to improve energy efficiency by reducing friction and turbulence in the system, which means less wasted energy and lower emissions. As a result, choosing high-quality expansion joints isn't just a matter of economics or practicality – it's also an important step toward sustainable and responsible operations.All of these factors combine to make the Bellows Type Expansion Joints from this manufacturer an excellent choice for a wide variety of industrial applications. Whether you're working in the chemical, petrochemical, power generation, or HVAC sectors, these components provide reliable performance, cost savings, and environmental benefits that simply can't be matched by other solutions.With a long track record of success, a strong focus on R&D and customer service, and a commitment to sustainability, this manufacturer is poised to continue leading the way in the expansion joint industry for years to come. If you're looking to improve the performance and safety of your industrial systems, consider making these high-quality components a part of your plan – they just might be the perfect solution for your needs.

Discover the Importance and Benefits of Slip Expansion Joints for Efficient Infrastructure

Slip Expansion Joint: Advancing Infrastructure and Ensuring SafetyIntroduction:In today's ever-evolving world, the need for robust infrastructure becomes increasingly significant. Cities are expanding, bridges are being built, and roads are being developed to accommodate the growing population. However, with this development comes the challenge of ensuring the safety and functionality of these structures. Slip Expansion Joint (SEJ), a renowned name in the industry, has emerged as a leading solution provider in the field of expansion joints, making significant contributions to advancing infrastructure and safety.With a commitment to delivering high-quality and innovative solutions, SEJ has been operational for several years. Their expansion joints serve as a crucial element in bridges, buildings, and roads by allowing controlled movement between adjacent sections. These joints ensure that structures can adapt to changing environmental conditions, including temperature fluctuations, seismic vibrations, and traffic loads. By minimizing the impact of these factors, Slip Expansion Joint plays an invaluable role in the longevity and reliability of infrastructure projects.Flexibility and Adaptability:One of the standout features of SEJ's expansion joints is their ability to exhibit exceptional flexibility and adaptability. These joints can accommodate various forms of movement, including lateral, rotational, and vertical displacement, thereby absorbing stress and minimizing impact on the surrounding structures. Being designed for both road and bridge applications, SEJ's expansion joints offer unparalleled functionality and durability across diverse projects, from highway networks to tall buildings.Innovation and Technology:To maintain their position as industry leaders, Slip Expansion Joint constantly invests in research and development, enabling them to integrate the latest technological advancements into their products. Innovative materials and engineering techniques culminate in expansion joints that possess superior performance characteristics, ensuring their reliability, longevity, and safety. Additionally, the utilization of cutting-edge computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows SEJ to deliver precise and customized solutions for each infrastructure project.Quality Assurance:As a responsible player in the industry, Slip Expansion Joint places immense importance on quality control and adherence to international standards. To guarantee the highest quality of their products, SEJ conducts rigorous testing at every stage of production. These tests assess factors such as structural integrity, load-carrying capacity, and resistance to environmental factors, ensuring that their expansion joints meet or exceed industry requirements. By prioritizing quality assurance, SEJ instills confidence in their clients about the reliability and safety of their infrastructure components.Environmental Responsibility:SEJ embraces their role as a contributor to sustainable development, integrating environmentally friendly practices into their operations. By utilizing materials that possess low carbon footprints and introducing energy-efficient processes throughout manufacturing, Slip Expansion Joint minimizes the negative impact on the environment. In doing so, they demonstrate their commitment to creating infrastructure solutions that align with the principles of environmental sustainability.Collaboration and Client Engagement:Slip Expansion Joint goes beyond simply offering products; they proactively engage with clients, providing comprehensive assistance and support throughout the project implementation process. By fostering collaborative relationships, SEJ ensures that the unique requirements of each project are met and guarantees the highest level of satisfaction. Their experienced team of engineers and consultants work closely with clients to understand their specific needs and provide tailored solutions, helping them optimize their infrastructure development.Conclusion:In an ever-changing world that demands resilient and safe infrastructure, Slip Expansion Joint is at the forefront of delivering innovative expansion joint solutions. Their commitment to flexibility, adaptability, innovation, quality assurance, environmental responsibility, and client engagement sets them apart. By continuing to push boundaries and embrace evolving technologies, Slip Expansion Joint remains a trusted partner in advancing infrastructure and ensuring the safety and longevity of our built environment.

Ultimate Guide to Pump Flexible Joints: What You Need to Know

Pump Flexible Joint, a key component in the machinery industry, has become an essential product in various industrial applications. It has the capability to absorb vibration, reduce noise, and compensate for misalignment, thereby contributing to the smooth operation of different types of pumps. As a leading manufacturer of these crucial components, {Company Name} has been at the forefront of delivering high-quality and innovative solutions to meet the unique needs of its clients.{Company Name} was established in the early 2000s with a mission to provide top-notch pump accessories and components to businesses worldwide. With a strong emphasis on research and development, the company has continuously strived to enhance its product line and develop new technologies that align with the evolving needs of the industry. This commitment has enabled {Company Name} to gain a strong foothold in the market and establish itself as a trusted and reliable supplier of pump flexible joints.The pump flexible joints manufactured by {Company Name} are engineered to withstand the rigors of industrial environments. They are made from high-quality materials, ensuring durability and longevity. Moreover, the company’s dedication to quality control and testing procedures guarantees that each flexible joint meets stringent industry standards and specifications.One of the key features of {Company Name}’s pump flexible joints is their flexibility and adaptability. They are designed to accommodate a wide range of movements and vibrations, making them suitable for various types of pumps and piping systems. This versatility has made {Company Name} a preferred choice for businesses looking for reliable and cost-effective solutions for their pumping needs.In addition to its product quality, {Company Name} is also known for its exceptional customer service. The company’s team of experts is committed to providing comprehensive support to clients, from selecting the right flexible joint for their specific requirements to offering technical assistance and guidance throughout the installation and maintenance processes.As the demand for pump flexible joints continues to grow, {Company Name} has been proactive in expanding its production capacity and optimizing its manufacturing processes. The company has invested in advanced machinery and technology to enhance efficiency and productivity, allowing it to fulfill large orders and meet tight deadlines without compromising on quality.Furthermore, {Company Name} has been dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, from sourcing raw materials to waste management, to minimize its ecological footprint. This commitment to sustainability has not only earned {Company Name} a positive reputation in the industry but has also contributed to its long-term success and growth.Looking ahead, {Company Name} is poised to continue its trajectory of success in the market for pump flexible joints. The company remains focused on innovation and diversification, exploring new opportunities and partnerships to further expand its product offerings and reach new markets. With a steadfast commitment to excellence and customer satisfaction, {Company Name} is set to remain a leader in the industry and a go-to choice for businesses seeking reliable pump accessories and components.In conclusion, {Company Name} has etched its name as a pioneer in the manufacturing of pump flexible joints, setting industry standards for quality, reliability, and innovation. With a strong focus on customer satisfaction, sustainability, and continuous improvement, the company is well-positioned to meet the evolving needs of the market and maintain its position as a key player in the industry.

Effective Solutions for Rubber Expansion Joints with Threaded Unions

Title: Innovative Threaded Union Rubber Expansion Joint Sets New Standards in Industrial Piping Solutions Introduction (100 words):In the constantly evolving field of industrial piping solutions, a pioneering company has emerged with a groundbreaking product that is revolutionizing the industry. Threaded Union Rubber Expansion Joint, developed by an industry-leading company, offers an innovative and efficient solution for pipe connection applications. Boasting exceptional performance, flexibility, and durability, this expansion joint is set to redefine the market, providing engineers and professionals across a wide range of sectors with a reliable and high-quality solution.Body:1. The Importance of Robust Pipe Connections (150 words):Ensuring reliable and leak-free pipe connections is crucial for industrial applications. Piping systems are used extensively across industries such as chemical, petrochemical, oil and gas, wastewater treatment, power generation, and HVAC. Failure in these systems can lead to significant operational disruptions, financial losses, and even safety hazards. Hence, industry professionals constantly seek better solutions to enhance the stability, flexibility, and longevity of their pipe connections.2. Introducing Threaded Union Rubber Expansion Joint (150 words):Threaded Union Rubber Expansion Joint is an advanced product that addresses the challenges faced by industrial piping systems. Built on cutting-edge technology, this expansion joint is designed to provide exceptional performance and reliability in demanding environments. The joint combines rubber and metal components to form a flexible connection that can absorb vibrations, compensate for thermal expansion, and reduce noise.3. Key Features and Benefits (200 words):a. Versatility: Threaded Union Rubber Expansion Joint caters to different pipe materials, diameters, and working pressures. It can be adapted to various installation requirements, making it suitable for a wide range of industrial applications.b. Flexibility: The joint's elastomeric construction allows it to absorb movement and stress, compensating for thermal expansion, contraction, and misalignment. This flexibility minimizes the risk of pipe failure and reduces fatigue on the system, extending the lifespan of the overall piping network.c. Enhanced Durability: The joint's robust design ensures resilience to harsh operating conditions, such as exposure to chemicals, high temperatures, and corrosive substances. This makes it ideal for industries that demand long-lasting and reliable performance.d. Noise and Vibration Reduction: The joint significantly reduces the transmission of noise and vibrations, enhancing safety and creating a quieter working environment.e. Easy Installation and Maintenance: Threaded Union Rubber Expansion Joint features a user-friendly design that simplifies installation, with reduced downtime and no special tools required. Routine maintenance is straightforward, ensuring hassle-free upkeep of the piping system.4. Market Impact and Future Prospects (150 words):The introduction of Threaded Union Rubber Expansion Joint is poised to create a significant impact on the market for industrial piping solutions. With its superior capabilities, the joint can enhance the operational efficiency, reliability, and safety of a wide range of industries. The product's potential to reduce downtime, minimize maintenance costs, and extend the service life of the piping system makes it an appealing choice for engineers and professionals.Looking ahead, this innovative expansion joint is expected to contribute to the ongoing development of high-performance piping systems, offering a sustainable and cost-effective solution. In a rapidly growing industrial landscape, where reliability and robustness are essential, Threaded Union Rubber Expansion Joint sets a new benchmark for the industry, ensuring seamless pipe connections that are built to withstand the most challenging conditions.Conclusion (100 words):Threaded Union Rubber Expansion Joint offers an innovative solution for industrial piping systems, providing a combination of exceptional performance, versatility, and reliability. With its ability to absorb stress, reduce noise and vibrations, and resist the harshest operating conditions, this expansion joint is set to redefine the industry standards. As professionals across various industrial sectors demand reliable and robust piping solutions, the Threaded Union Rubber Expansion Joint emerges as a game-changer, revolutionizing the way we approach pipe connections.

Expertly Assembling Hydraulic and Pneumatic Solutions In-House -Stocking a Wide Range of Components

Hydraulic Expansion Joints: Improving your Industrial EquipmentIf you work in the industrial sector, you’re probably familiar with the need for industrial equipment to stay operational around the clock. When industrial equipment is regularly exposed to high temperatures, fluctuations in pressure, or other environmental factors, it can cause wear and tear, leading to equipment failure and costly repairs.Fortunately, hydraulic expansion joints can help mitigate the risk of equipment failure, ensuring your machines stay operational and your production line stays on track. In this blog post, we’ll explore the benefits of hydraulic expansion joints and how working with a hydraulic equipment supplier like Air Hydro Power can help you get the most out of your equipment.What Are Hydraulic Expansion Joints?Hydraulic expansion joints, also known as compensators, are specialized components that are installed in industrial piping systems to absorb the movement caused by temperature and pressure fluctuations. When a piping system changes temperature, two phenomena occur simultaneously: the length of the pipe will expand or contract, and the pressure inside the pipe will change. Hydraulic expansion joints allow for the movement of pipe sections while maintaining the integrity of the piping system.Moreover, hydraulic expansion joints help reduce equipment failure by absorbing vibrations and shock. This ensures even distribution of pressure and minimizes premature wear and tear to your equipment. Hydraulic expansion joints can also improve the efficiency and lifespan of your piping system by reducing overall stress and strain on the system.Why Use Hydraulic Expansion Joints?Hydraulic expansion joints are particularly valuable for industrial applications where movement is a critical factor. Here are a few reasons why investing in hydraulic expansion joints could pay off:1. Temperature and Pressure FluctuationsHave you ever experienced a buzzing sound or even felt shaking in the pipes during operation? This may be caused by thermal and pressure movements, which can eventually cause damage to your piping system. Hydraulic expansion joints compensate for this movement, reducing excess pressure, and internal stress.2. Reduced Vibration and ShockPumps, motors, and compressors all generate vibration and shock that can cause damage to the entire piping system. Hydraulic expansion joints help minimize these effects by absorbing the vibrations, eliminating shock loads, and reducing the likelihood of equipment failure.3. Long-lasting and Reliable EquipmentUsing hydraulic expansion joints in your piping system can prolong the lifespan and improve the reliability of your equipment. By reducing stress, vibration, and shock, hydraulic expansion joints help improve your equipment’s overall performance, minimize downtime, and extend its service life.How Air Hydro Power Can HelpIf you’re looking for a reliable supplier of hydraulic equipment, Air Hydro Power has you covered. Our team of experts has been providing industrial solutions for over 47 years, and we’re dedicated to offering only the highest quality products and services to our clients.We stock standard and hard-to-find components, including hydraulic expansion joints, and we build each assembly in-house to ensure quality and consistency. We also offer custom solutions, allowing our team to create unique hydraulic systems fitted to your specific needs.ConclusionHydraulic expansion joints are critical components that can improve the efficiency and lifespan of your industrial equipment. By compensating for thermal and pressure movements, reducing vibration and shock, and improving overall system performance, hydraulic expansion joints are an essential investment for any industrial operation.Air Hydro Power is here to help you get the most out of your hydraulic equipment. We offer reliable, high-quality hydraulic expansion joints, along with custom solutions, to ensure your equipment stays operational and runs smoothly. Contact us today to learn more about our hydraulic equipment and industrial solutions.

Ultimate Guide: Optimizing Metallic Bellows Designs for Enhanced Performance

Metallic Bellows Design: A Revolution in Industrial EngineeringIn the world of industrial engineering, companies are constantly striving to develop innovative solutions that improve the efficiency and reliability of complex systems. One such breakthrough comes in the form of metallic bellows design, a revolutionary technology that promises to redefine the way industries operate. This cutting-edge design, developed by an industry-leading company, has already garnered significant attention and is set to transform various sectors worldwide.This groundbreaking metallic bellows design, pioneered by [Company Name], represents a significant leap forward in the field of industrial engineering. By incorporating state-of-the-art materials and engineering principles, these bellows are capable of withstanding extreme conditions while providing unparalleled performance and longevity.[Company Name], a trailblazer in the engineering industry, has a formidable reputation for continually pushing boundaries and spearheading innovation. With decades of experience in designing and manufacturing high-quality industrial systems, the company is now revolutionizing the way industries function with its metallic bellows design.Traditionally, bellows, typically made of rubber or fabric, have been used to compensate for thermal expansion, vibrations, and other stresses in industrial systems. However, these conventional bellows often fall short when it comes to durability and performance. With the advent of metallic bellows design, these limitations are effectively addressed.The key advantage of metallic bellows design lies in its unique composition. Constructed using advanced alloys and precision manufacturing processes, these bellows are incredibly robust and resistant to extreme temperatures, pressure differentials, and corrosive environments. This inherent durability ensures that industrial systems can run smoothly and efficiently, even in the harshest conditions.Moreover, the design of metallic bellows enables them to compensate for complex movements and vibrations with exceptional accuracy. This flexibility, combined with the ability to absorb stress, guarantees the longevity of critical components within industrial systems. Consequently, businesses can experience reduced maintenance costs, minimal downtime, and enhanced operational efficiency, leading to improved productivity and profitability.[Company Name]'s metallic bellows design has applications across various industries, including oil and gas, aerospace, automotive, and petrochemicals, to name a few. For instance, in the oil and gas sector, where equipment is subjected to extreme pressures and temperatures, these bellows offer a reliable solution for compensating thermal expansion in pipelines and valves. In the aerospace industry, metallic bellows find applications in aircraft engines, where they effectively absorb vibrations and compensate for thermal stresses.Recognizing the immense potential of this revolutionary design, [Company Name] is investing significantly in research and development. By partnering with leading research institutions and collaborating with industry experts, the company strives to constantly improve and expand the capabilities of metallic bellows design.Furthermore, [Company Name] places immense emphasis on quality and adherence to international standards. Manufacturing facilities are equipped with state-of-the-art technology and operated by highly skilled technicians. Rigorous quality control measures are in place to ensure that every metallic bellows produced meets the most demanding specifications, providing customers with products of unrivaled reliability and performance.In conclusion, metallic bellows design is a game-changer in the world of industrial engineering. [Company Name]'s pioneering work in this field is set to transform various sectors, offering unparalleled reliability, durability, and performance. As industries continue to evolve and demand more sophisticated solutions, metallic bellows design will undoubtedly play a pivotal role in shaping the future of industrial systems.

Durable Sliding Type Expansion Joint for Efficient Bridge Maintenance

Today, cutting-edge technology and innovative solutions have become imperative in ensuring the integrity and longevity of infrastructure. In line with this, the {{Company Name}} is proud to introduce its latest innovation in the field of expansion joints – the Sliding Type Expansion Joint (STEJ).The {{Company Name}} is a leading global provider of engineering solutions for infrastructure development and maintenance. With over 20 years of experience, the company has established a strong reputation for delivering high-quality products and services to clients worldwide. The {{Company Name}}’s commitment to innovation and excellence has driven its continuous growth and success in the industry.The Sliding Type Expansion Joint (STEJ) is the latest addition to the {{Company Name}}’s extensive range of expansion joint products. Designed to accommodate thermal expansion and contraction in structures, the STEJ offers superior performance and durability compared to traditional expansion joint systems. Its innovative design allows for smooth and seamless movement, reducing stress and potential damage to the structure.One of the key features of the STEJ is its sliding mechanism, which enables a controlled range of movement in response to thermal variations. This functionality is crucial in ensuring the stability and safety of infrastructure, particularly in bridges, highways, and other high-traffic areas. The STEJ’s ability to effectively manage movement and distribute loads contributes to the overall resilience and longevity of the structure.Moreover, the STEJ is engineered with high-quality materials that are resistant to corrosion, wear, and weathering. This ensures that the expansion joint can withstand harsh environmental conditions and maintain its performance over an extended period. With its low maintenance requirements, the STEJ offers a cost-effective solution for infrastructure owners and operators.In addition to its technical capabilities, the STEJ is also customizable to suit the specific requirements of different projects. The {{Company Name}}’s team of experienced engineers and technical experts work closely with clients to tailor the design, size, and performance of the expansion joint according to the project’s needs. This collaborative approach ensures that the STEJ seamlessly integrates into the overall structure and delivers optimal results.The introduction of the STEJ reflects the {{Company Name}}’s ongoing commitment to innovation and excellence in the field of infrastructure engineering. By continuously developing and refining its product offerings, the company aims to provide practical and efficient solutions that address the evolving needs of the industry. The STEJ exemplifies this dedication, offering a reliable and sustainable solution for managing structural movement in various infrastructural applications.Furthermore, the {{Company Name}} provides comprehensive support and technical expertise to clients implementing the STEJ in their projects. From initial consultation and design assistance to installation and maintenance services, the company ensures that its clients receive the necessary guidance and resources to maximize the performance of the expansion joint.In conclusion, the {{Company Name}}’s introduction of the Sliding Type Expansion Joint (STEJ) signifies a significant advancement in the field of infrastructure engineering. With its innovative design, durability, and customization options, the STEJ offers a versatile solution for managing structural movement and ensuring the longevity of infrastructure. As the industry continues to evolve, the {{Company Name}} remains at the forefront of technological innovation, providing cutting-edge solutions to meet the complex challenges of modern infrastructure development.

Key Insights About Rubber Flexible Joints: Enhancing Flexibility and Efficiency

[News Title]Rubber Flexible Joints: Revolutionizing Industrial Connectivity[News Introduction][Company Name], a leading innovator in the field of industrial connectivity solutions, is proud to introduce its latest product, the Rubber Flexible Joint. This groundbreaking technology promises to revolutionize the way industries connect different parts of their systems, providing improved functionality, longevity, and cost-effectiveness.[Body]1. The Problem with Traditional Joint SolutionsTraditional joint solutions in industrial systems often suffer from various limitations. These joints, made from rigid materials such as steel or PVC, tend to transmit vibrations, noise, and even force imbalances between connected components. This not only compromises the efficiency of the system but also leads to increased downtime, maintenance, and replacement costs.Furthermore, these rigid joints are prone to wear and tear due to continuous motion and environmental factors. Frequent replacements are required, resulting in substantial financial losses and potential disruption of critical operations.2. Introducing the Rubber Flexible JointThe Rubber Flexible Joint, developed by [Company Name], addresses the shortcomings of traditional joint solutions by employing innovative rubber technology. This proprietary rubber compound provides exceptional flexibility, enabling a wide range of motion and absorbing vibrations, shocks, and axial movements within the system.Using the Rubber Flexible Joint eliminates the transfer of unwanted forces and vibrations, ensuring smoother operation and reduced wear on the connected components. This enhanced flexibility not only extends the lifespan of the joint but also minimizes the need for maintenance and replacement, leading to significant cost savings for industries.3. Key Features and Benefits- Superior Flexibility: The Rubber Flexible Joint can accommodate angular, axial, and lateral movements, ensuring seamless connectivity in complex industrial environments. Its flexibility also minimizes the risk of mechanical failures caused by undue stress or force imbalances.- Vibration and Noise Reduction: With its unique rubber compound, the joint absorbs vibrations and suppresses noise, resulting in a quieter and more comfortable working environment.- Corrosion and Weather Resistance: The Rubber Flexible Joint is resistant to a wide range of chemicals, solvents, and environmental conditions. This ensures its longevity and operational reliability even in harsh industrial settings.- Easy Installation and Maintenance: The joint's design allows for simple and time-efficient installation, saving valuable labor costs. Additionally, its low maintenance requirements translate into decreased downtime and increased productivity.- Versatile Applications: The Rubber Flexible Joint can be used in various industries, including manufacturing, oil and gas, mining, construction, and water treatment plants, among others. Its compatibility with different systems and components makes it a versatile choice for connectivity solutions.4. Industry Feedback and Future ProspectsEarly adopters of the Rubber Flexible Joint have expressed their satisfaction with its performance and reliability. Industrial experts have hailed it as a game-changer, significantly improving the overall productivity and efficiency of their operations.The success of the Rubber Flexible Joint has paved the way for further advancements in industrial connectivity solutions. [Company Name] remains committed to continuous research and development to address the evolving needs of the industry and provide cutting-edge solutions to its customers.[Conclusion]With the introduction of the Rubber Flexible Joint, [Company Name] has solidified its position as an industry leader in innovative connectivity solutions. This groundbreaking technology, with its enhanced flexibility, durability, and cost-effectiveness, is set to transform the way industries connect their systems. By reducing maintenance requirements, increasing efficiency, and improving overall system performance, the Rubber Flexible Joint offers a brighter and more sustainable future for the industrial landscape.

Key Advantages of Fabric Joints in Various Applications

Fabric Joints: A Reliable Solution for Industrial ApplicationsIn the world of heavy-duty industrial applications, the importance of reliable and durable fabric joints cannot be overstated. These crucial components play a vital role in connecting and sealing various parts in a wide range of machinery and equipment. As the demand for high-performance fabric joints continues to rise, it has become imperative for companies to seek out trusted and proven suppliers in the industry.One such company that has earned a stellar reputation in providing top-quality fabric joints is {}. With a strong focus on innovation, quality, and customer satisfaction, {} has emerged as a leading provider of fabric joints for industrial applications. From large-scale manufacturing plants to heavy machinery operations, their fabric joints have been widely adopted across a diverse range of industries.The key to the success of {} lies in their unwavering commitment to excellence. Their fabric joints are designed and manufactured with precision using advanced materials and cutting-edge techniques, ensuring superior performance and longevity in the most demanding environments. Whether it's high temperatures, extreme pressures, or corrosive chemicals, {} fabric joints are engineered to deliver unmatched reliability and durability.One of the standout features of {} fabric joints is their exceptional resistance to wear and tear. This is especially crucial in industrial settings where the performance of machinery and equipment directly impacts productivity and safety. By incorporating high-strength fabrics and specialized coatings, {} fabric joints are able to withstand continuous use and harsh operating conditions without compromising their sealing capabilities.Furthermore, {} offers a comprehensive range of fabric joints to meet the unique needs of different industries and applications. From standard sizes to custom configurations, their diverse product lineup caters to a wide spectrum of requirements, making them a preferred choice for businesses seeking tailor-made solutions for their specific needs.In addition to their commitment to product excellence, {} is also dedicated to providing unparalleled customer support. Their team of technical experts works closely with clients to understand their challenges and develop bespoke fabric joint solutions that address their individual operational needs. This personalized approach has earned {} a loyal customer base that relies on their expertise and responsiveness to keep their operations running smoothly.Looking ahead, {} continues to raise the bar in the field of fabric joint technology. By investing in research and development, they are constantly exploring new materials, designs, and manufacturing processes to further enhance the performance and durability of their fabric joints. This forward-thinking approach ensures that {} remains at the forefront of the industry, delivering innovative solutions that empower businesses to achieve peak efficiency and reliability.In conclusion, {} has established itself as a trusted and respected provider of fabric joints for industrial applications. With a steadfast dedication to quality, innovation, and customer satisfaction, they have earned the confidence of businesses looking for dependable sealing solutions for their critical operations. As the demand for high-performance fabric joints continues to grow, {} is well-positioned to lead the way with their proven expertise and unwavering commitment to excellence.

PVC, Rigid and Flexible Plastic Pipes and Tubes in India: Contact Details and Addresses

In India, the PVC and plastics industry has been booming for years, and one of the most important sectors within this industry is the Pipes and Tubes - PVC / Rigid Plastics / Flexible Plastics sector. This sector is responsible for providing essential pipes and tubes for various industries, including plumbing, irrigation, construction, and more.There are many companies in India that provide a range of pipes and tubes, including PVC, rigid plastics, and flexible plastics. These companies offer high-quality products that are widely used throughout the country.PVC pipes and tubes are made from a type of plastic called polyvinyl chloride. This material is strong and lightweight, making it an ideal choice for many different applications. PVC pipes and tubes are widely used in plumbing, irrigation, and construction industries because of their durability, low cost, and easy installation.In contrast, rigid plastic pipes and tubes are made from materials that are more robust and can handle higher pressure, temperatures, and chemical exposure. These rigid pipes and tubes are used for a wide range of industrial applications, including sewage and drainage systems, water treatment plants, and chemical manufacturing.Flexible plastic pipes and tubes are also prevalent in India and are used in many different industries. These pipes are flexible and can bend to fit into tight spaces, which makes them an excellent choice for plumbing and irrigation systems, where pipes need to be installed in narrow areas.Flexible Pipe Connection is an essential aspect of these pipes and tubes in India. It is the point where two pipes or tubes are joined together through a flexible connection. It helps to provide a watertight seal and allows for some flexibility, preventing breakage or leakage that might occur if the pipes were rigidly connected.In conclusion, the Pipes and Tubes - PVC / Rigid Plastics / Flexible Plastics sector is a crucial component of the plastics industry in India. These pipes and tubes are used widely in various industries, and their quality and durability are critical to the success of many Indian businesses. With their exceptional performance, these pipes and tubes have established themselves as a valuable asset to the growth of various sectors in the country.