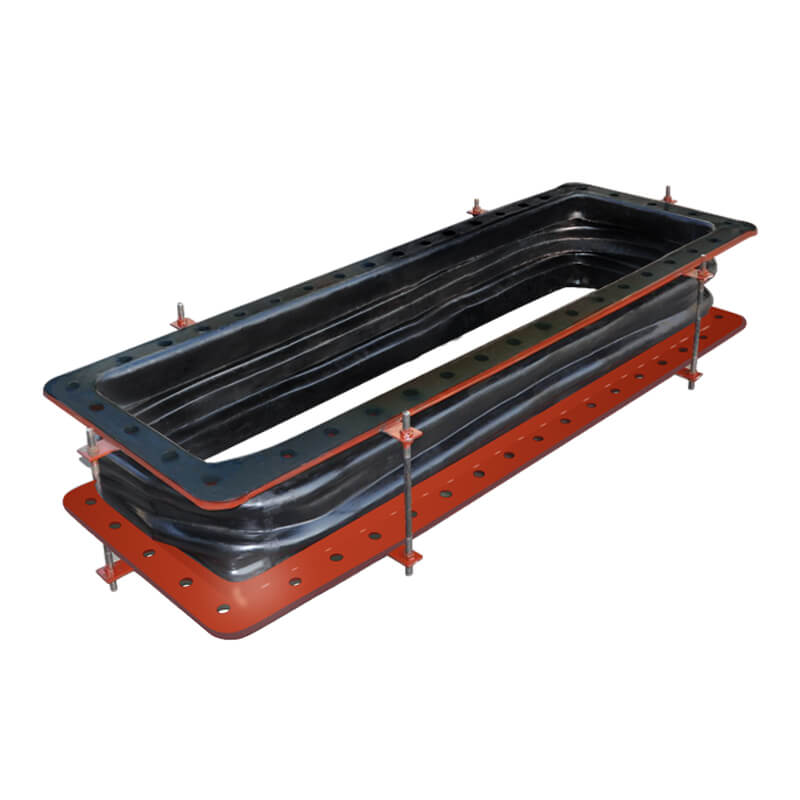

Durable and Flexible Expansion Joints for Industrial Applications

By:Admin

With a wide range of products and solutions, the company has earned a reputation for excellence and innovation. Its expansion joints are used in a variety of industries, including power generation, oil and gas, petrochemical, and more. The company's commitment to quality and customer satisfaction has made it a trusted partner for many companies around the world.

One of the key features of the company's expansion joints is their ability to withstand extreme temperatures, pressure, and corrosive environments. This durability ensures that the joints can effectively handle the rigorous demands of industrial applications while maintaining their integrity and reliability.

In addition to their exceptional performance, the expansion joints offered by Bellows Expansion Joint are also designed with ease of installation and maintenance in mind. This ensures that clients can easily integrate the joints into their existing systems without experiencing any disruptions to their operations.

Furthermore, Bellows Expansion Joint places a strong emphasis on customization, recognizing that each client has unique requirements. The company's team of experts works closely with clients to understand their specific needs and develop tailored solutions that address their challenges.

The company's dedication to innovation is evident in its continuous research and development efforts. It constantly seeks out new materials and technologies to enhance the performance of its expansion joints, ensuring that they remain at the forefront of industry standards and regulations.

Moreover, Bellows Expansion Joint invests heavily in quality control processes to ensure that all its products meet the highest standards of quality and safety. This unwavering commitment to excellence has earned the company various certifications and accolades, affirming its position as a leader in the industry.

With a global presence, Bellows Expansion Joint has established a strong network of clients and partners. Its expansion joints have been used in various high-profile projects around the world, demonstrating their reliability and efficiency in diverse applications.

As the industrial sector continues to evolve and grow, the demand for high-performance expansion joints will only increase. Bellows Expansion Joint is well-positioned to meet this demand with its extensive range of products and its unwavering dedication to quality, innovation, and customer satisfaction.

In conclusion, Bellows Expansion Joint remains a trusted and reliable partner for companies seeking high-quality expansion joints. With its commitment to excellence, innovation, and customer satisfaction, the company is set to continue its success in the industrial sector for years to come.

Company News & Blog

Essential Guide to Hot Water Expansion Joints: What You Need to Know

Hot Water Expansion Joint: A Crucial Component in Plumbing SystemsIn the world of plumbing, there are many components that are necessary for ensuring the proper functioning of a system. One of these crucial components is the hot water expansion joint. This small but mighty device plays a vital role in preventing damage to water heaters, pipes, and other plumbing fixtures by allowing for the expansion and contraction of water as it heats and cools.The hot water expansion joint, also known as a thermal expansion tank, is a pressure vessel designed to absorb excess pressure caused by the increase in volume of water as it is heated. This is particularly important in closed water systems where there is no room for the water to expand. Without an expansion joint, the pressure within the system can build up to dangerous levels, leading to leaks, burst pipes, or even damage to the water heater itself.One of the leading manufacturers of hot water expansion joints is a global company that has been at the forefront of innovative plumbing solutions for over 50 years. With a focus on quality and reliability, this company has become a trusted name in the plumbing industry, providing a wide range of products designed to meet the needs of residential, commercial, and industrial customers.In addition to their high-quality products, the company also prides itself on its commitment to customer service and satisfaction. With a team of dedicated professionals, they are able to provide expert guidance and support to customers, ensuring that they have the right solution for their specific plumbing needs.One of the key features of the company's hot water expansion joints is their durable construction. Made from high-quality materials, these expansion joints are built to withstand the rigors of daily use, ensuring that they provide reliable performance for years to come. Additionally, the expansion joints are designed to be easy to install, making them a convenient and efficient solution for plumbers and homeowners alike.Furthermore, the company's expansion joints are designed to meet the highest standards of safety and performance. With rigorous testing and quality control procedures, customers can have confidence in the reliability and effectiveness of these products. This commitment to quality has earned the company a reputation as a leader in the industry, with their products being trusted by professionals and homeowners around the world.In addition to their hot water expansion joints, the company also offers a wide range of other plumbing solutions, including valves, fittings, and water heaters. With a comprehensive product line and a commitment to excellence, they are able to provide customers with everything they need to build and maintain a reliable and efficient plumbing system.As the demand for high-quality plumbing solutions continues to grow, the company remains dedicated to innovation and advancement. With a focus on research and development, they are constantly looking for new ways to improve their products and meet the evolving needs of their customers. This commitment to innovation has allowed the company to stay at the forefront of the industry, providing cutting-edge solutions that set the standard for performance and reliability.In conclusion, the hot water expansion joint is a crucial component in plumbing systems, and the company has established itself as a leading provider of these essential products. With a focus on quality, reliability, and innovation, they have earned a reputation as a trusted partner for professionals and homeowners alike. Whether it's for a residential, commercial, or industrial application, customers can rely on the company's hot water expansion joints to provide the safety, performance, and durability they need in their plumbing systems.

Suppliers of Bellows, Compensators, and Silicone Rubber Seals with Authentic Customer Reviews

Looking for reliable bellows suppliers? Look no further than one of the most trusted names in the industry – a leader in designing and manufacturing top-quality bellows, compensators, and silicone rubber seals that are used in a broad range of industrial applications.With years of experience in the industry, we have developed a reputation for excellence and reliability, thanks to our commitment to providing our customers with nothing but the best. Our product line is extensive, and we are confident that we have the perfect solution to meet your needs.As one of the leading bellows suppliers in the industry, we take great pride in our ability to deliver products that offer exceptional performance and long-lasting durability. Our products are designed to withstand the harsh environments and demanding conditions that are often found in industrial applications, ensuring that you can rely on them to get the job done.Our range of products includes everything from bellows and compensators to silicone rubber seals, all of which are designed to meet the highest standards of quality and performance. We use only the best materials and techniques to manufacture our products, ensuring that they are built to last and can withstand even the toughest conditions.Whether you are looking for a custom solution or something off-the-shelf, we have the expertise and experience to deliver the perfect product for your needs. We work closely with our customers to understand their specific requirements and to develop solutions that are tailored to their unique needs.In addition to our extensive range of products, we also offer unbeatable customer service and support. We are always available to answer your questions and provide technical advice, ensuring that you have all the information and support you need to make the right decision for your business.So if you are looking for a reliable bellows supplier that you can trust, look no further than one of the most respected names in the industry. With our commitment to quality, innovation, and customer satisfaction, we are the partner you need to help your business thrive. Contact us today to learn more!

Stainless Steel Braided Flexible Tap Connector for High-Pressure Applications

Flexible Tap Connectors: The Ideal Way to Connect Taps and AppliancesOne of the key components in any plumbing system is the tap connector. Tap connectors are used to join pipework to appliances or taps and come in a variety of materials and designs. One of the most popular types of tap connectors is the flexible tap connector, which offers numerous benefits and advantages over traditional rigid pipework connections.In this blog post, we will take a closer look at flexible tap connectors, their features, and the reasons why they are the ideal way to connect taps and appliances in any plumbing system.What Is a Flexible Tap Connector?A flexible tap connector is a type of flexible hose that is designed to connect taps and other appliances to the water supply. It is made up of a stainless steel over braided EPDM rubber tube that is reinforced with a flexible steel mesh. This design provides excellent flexibility, durability, and strength, making it ideal for use in a variety of plumbing applications.Flexible tap connectors are available in a range of sizes and lengths to suit different plumbing systems. They typically come with one compression end and a swivel nut with a washer on the other end, which allows for easy and quick installation.Features of Flexible Tap ConnectorsStainless Steel Over Braided EPDM Rubber Tube: The main feature of a flexible tap connector is the stainless steel over braided EPDM rubber tube. This material is highly durable and resistant to corrosion, making it ideal for use in wet and humid environments.Nickel Plated Brass Fittings: The fittings that come with flexible tap connectors are made from nickel plated brass. This gives them excellent strength and durability, as well as protection against corrosion.15 Bar Max Working Pressure: Flexible tap connectors are designed to withstand high pressure and are rated at a maximum working pressure of 15 bar. This makes them suitable for use in a variety of plumbing systems.One Compression End & Swivel Nut: Flexible tap connectors come with a compression end and a swivel nut at the other end. This allows for easy installation and makes it easy to connect taps and appliances to the plumbing system.70C Max Temp: Flexible tap connectors are designed to operate in temperatures of up to 70C, making them suitable for use in hot water systems.Advantages of Flexible Tap ConnectorsEasy to Install: Flexible tap connectors are incredibly easy to install. They are designed to be flexible, which means they can be easily bent and manoeuvred into place, making installation quick and straightforward.Reduced Leak Risk: Traditional rigid pipework connections can often be prone to leaks. However, flexible tap connectors are designed to reduce the risk of leaks, thanks to their strong and durable construction.Flexible Design: The flexible design of flexible tap connectors means they can be easily and quickly adjusted to fit the requirements of different plumbing systems. This makes them a versatile solution that can be used in a wide variety of applications.Reduced Noise: The flexible design of flexible tap connectors can also help to reduce noise in the plumbing system. This makes them ideal for use in residential and commercial buildings, where noise can be an issue.Improved Aesthetics: Flexible tap connectors are also available in a range of colours and styles, which means they can be matched to the design and colour scheme of different plumbing systems. This can help to improve the overall aesthetics of the system.ConclusionFlexible tap connectors are an essential component in any plumbing system. They provide numerous benefits, including flexibility, durability, and ease of installation. They are also available in a variety of sizes, lengths, and styles, making them suitable for use in a wide range of applications. If you are looking to improve your plumbing system's performance, then flexible tap connectors are the ideal solution. So, why not invest in flexible pump connectors today?

Innovative Double Sphere Flexible Connector Unveiled in Latest News

Double Sphere Flexible Connector, a groundbreaking product in the field of industrial piping, has just been introduced by a leading manufacturer in the industry. This innovative connector is designed to provide maximum flexibility and movement in piping systems, while maintaining the integrity of the connection.With the increasing demand for reliable and durable piping systems in industries such as oil and gas, petrochemical, water treatment, and power generation, the need for high-quality flexible connectors has become more important than ever. The Double Sphere Flexible Connector is designed to meet this demand, offering a range of features that set it apart from traditional connectors.The Double Sphere Flexible Connector is able to absorb thermal expansion, vibration, and misalignment in piping systems, making it a versatile and reliable solution for a wide range of applications. Its unique design, with two spheres providing flexibility in all directions, ensures that the connector can accommodate movement without compromising the integrity of the piping system.In addition to its flexibility, the Double Sphere Flexible Connector is also highly durable, with a robust construction that is able to withstand high temperatures, corrosive environments, and high pressure. This makes it an ideal choice for use in demanding industrial applications where reliability is paramount.The company behind the Double Sphere Flexible Connector is renowned for its expertise and experience in the design and manufacture of high-quality piping products. With a long history of providing innovative solutions to the industry, the company has established itself as a trusted and reliable partner for companies seeking superior piping products.In addition to its technical expertise, the company is also committed to delivering exceptional customer service, with a team of experienced professionals on hand to provide support and assistance to clients. This commitment to customer satisfaction sets the company apart from its competitors, ensuring that clients receive not only high-quality products, but also the support and guidance they need to make the most of these products.The introduction of the Double Sphere Flexible Connector represents a significant milestone for the company, demonstrating its ongoing commitment to innovation and excellence in the field of industrial piping. With this groundbreaking product, the company is poised to further strengthen its position as a leader in the industry, providing clients with the reliable and durable solutions they need to succeed in their respective fields.As the demand for high-quality piping products continues to grow, the Double Sphere Flexible Connector is expected to become an essential component in a wide range of industrial applications. Its combination of flexibility, durability, and reliability makes it an ideal choice for companies seeking to ensure the integrity and performance of their piping systems.With its introduction, the company has once again demonstrated its ability to deliver innovative solutions that meet the evolving needs of the industry. As companies continue to seek reliable and durable piping products, the Double Sphere Flexible Connector is poised to become a key component in the success of many industrial operations.

Benefits and Applications of Expansion Joints in Piping Systems

Expansion Joints Piping is a critical aspect of the piping industry, allowing for movement, vibration, and thermal expansion in a pipeline. This essential component helps to prevent damage to piping systems, ensuring their longevity and reliability. With the increasing demand for expansion joints in various industries, it is crucial for companies to provide high-quality and reliable products to meet the needs of their customers.In this regard, {Company Name}, a leading manufacturer of expansion joints, has been at the forefront of providing innovative and efficient solutions for the piping industry. With years of experience and expertise in the field, {Company Name} has established itself as a trusted name, delivering top-notch products and exceptional customer service.{Company Name} offers a wide range of expansion joints, including metal, fabric, rubber, and PTFE expansion joints, catering to diverse needs and applications in industries such as oil and gas, petrochemical, power generation, water and wastewater, and many others. The company's commitment to quality, performance, and durability has made it a preferred choice for engineers, contractors, and end-users worldwide.One of the key factors that set {Company Name} apart from its competitors is its dedication to innovation and continuous improvement. The company invests heavily in research and development to create new and advanced solutions that address the evolving challenges in the piping industry. By staying ahead of the curve, {Company Name} ensures that its expansion joints are always at the cutting edge of technology, meeting or exceeding industry standards and customer expectations.Moreover, {Company Name} places a strong emphasis on quality control and testing to guarantee the reliability and performance of its products. The company follows rigorous manufacturing processes and conducts thorough inspections to ensure that each expansion joint meets the highest standards of quality and safety. By adhering to strict quality measures, {Company Name} instills confidence in its customers, assuring them of the integrity and longevity of its products.In addition to its commitment to quality and innovation, {Company Name} prides itself on its exceptional customer service and support. The company works closely with its clients to understand their specific requirements and provide tailored solutions that best suit their needs. With a team of knowledgeable and experienced professionals, {Company Name} offers technical expertise, guidance, and assistance throughout the entire process, from product selection to installation and maintenance.As part of its dedication to customer satisfaction, {Company Name} also offers comprehensive training programs and resources to educate and empower its customers. By sharing its expertise and knowledge, the company enables its clients to make informed decisions and maximize the benefits of its expansion joints, ultimately contributing to the success and efficiency of their operations.Looking ahead, {Company Name} is poised for further growth and expansion, driven by its unwavering commitment to excellence and customer-centric approach. With a strong focus on innovation, quality, and customer service, the company is well-positioned to meet the evolving demands of the piping industry and continue its legacy as a trusted provider of expansion joints.In conclusion, expansion joints piping plays a crucial role in the integrity and performance of piping systems, and {Company Name} has proven itself as a frontrunner in delivering high-quality, innovative, and reliable solutions. With its strong emphasis on quality, innovation, and customer service, {Company Name} continues to set the standard for excellence in the industry, ensuring the success and satisfaction of its customers.

Rubber Expansion Bellows Dimensions: Choosing the Right Fit for Your ApplicationWhen it comes to ensuring the safe and efficient operation of pipelines and machinery, rubber expansion joints and bellows play a crucial role. These flexible elements help compensate for movements, absorb vibrations, and reduce noise, ultimately protecting equipment and extending its lifespan. As premier suppliers of rubber expansion joints in the UAE, we understand the diverse needs of our clients and provide a wide range of options to meet those needs.One of the critical factors to consider while selecting rubber expansion joints or bellows is their dimensions. Accurate dimensioning ensures a proper fit, preventing leaks, pressure imbalances, and potential damages to the system. In this blog, we will explore the importance of rubber expansion bellows' dimensions and ways to choose the right fit for your application.Understanding Rubber Expansion Bellows DimensionsRubber expansion bellows are designed to accommodate various movements caused by thermal expansion, vibrations, pressure changes, or misalignments between pipes and equipment. The dimensions of expansion bellows play a significant role in determining their performance and ability to withstand these movements.Diameter:The outer and inner diameters of rubber expansion bellows directly impact their functionality. The outer diameter should match the respective pipe size, ensuring proper alignment and connection. On the other hand, the inner diameter determines the flow capacity of the system. It is crucial to select an expansion bellows with an inner diameter that matches the flow requirements of your specific application.Length:The length of rubber expansion bellows refers to the distance between the flange faces when the bellows is fully extended or compressed. This dimension is crucial to ensure the bellows' ability to absorb movements without overstressing or compressing beyond its designed limits. Determining the correct length is crucial to maintain the overall integrity and performance of the system.Movement Capability:The movement capability of rubber expansion bellows is closely linked to their dimensions. It is essential to consider the anticipated axial, lateral, and angular movements that the bellows will experience in your application. These movements may arise from changes in temperature, pressure, or vibrations. Choosing bellows with appropriate dimensions and movement capabilities ensures the desired flexibility and durability of the system.Thickness:The thickness of rubber expansion bellows determines their resilience and resistance to pressure and external forces. Thick-walled bellows provide better resistance to external impacts but may reduce their flexibility. Conversely, thin-walled bellows may provide increased flexibility but may compromise their long-term durability. Selecting the right thickness requires careful consideration of the specific operating conditions and the required balance between flexibility and durability.Pressure Ratings:The dimensions of rubber expansion bellows also contribute to their pressure ratings. Components of different dimensions, such as wall thickness and bellows length, have varying pressure resistance capabilities. It is essential to choose bellows with appropriate pressure ratings to ensure safe and efficient operation within your system.Choosing the Right Rubber Expansion Bellows DimensionsTo ensure optimal performance and reliability, consider the following factors when selecting rubber expansion bellows dimensions for your application:1. Understand the application requirements and operating conditions, including temperature fluctuations, pressure variations, and the types of movements the bellows needs to accommodate.2. Consult with experts in the field, such as our knowledgeable team, who can guide you in selecting the appropriate dimensions based on your specific needs.3. Evaluate the compatibility of the selected dimensions with your existing system components, ensuring a proper fit and connection.4. Regularly inspect and assess the performance of the rubber expansion bellows over time to ensure they continue to meet the system's needs adequately.ConclusionRubber expansion bellows are essential components in numerous industrial applications, providing flexibility and protection to pipelines and machinery. By carefully considering dimensions, such as diameter, length, movement capability, thickness, and pressure ratings, you can select the right rubber expansion bellows for your specific application.As the premier supplier of expansion joints in the UAE, we offer an extensive range of rubber expansion bellows, utilizing our expertise to ensure the perfect fit for your system. Contact us today to explore our extensive selection and benefit from our knowledgeable team's advice for optimal performance and longevity of your system.

Discover the Latest Advancements in Compensator Joint Technology

Compensator Joint Revolutionizes Industrial Machinery with Innovative TechnologyIn the fast-paced industrial world, the need for efficient and reliable machinery is crucial for businesses to stay competitive. In the heart of this burgeoning industry, lies a company that has been making waves with its cutting-edge technology and innovative solutions. {Company Name} is a leading manufacturer of state-of-the-art industrial machinery, dedicated to pushing the boundaries of what's possible in the world of engineering.Their latest breakthrough comes in the form of the revolutionary Compensator Joint, a game-changing technology that is set to redefine the way industrial machinery operates. This remarkable invention has been designed to address the common challenges and limitations faced by traditional mechanical joints. With its advanced design and intelligent engineering, the Compensator Joint offers a level of durability, flexibility and precision that has been previously unattainable.The Compensator Joint stands out for its ability to adjust and compensate for variations in alignment, making it ideal for use in a wide range of industrial applications. Whether it's in heavy-duty machinery, conveyor systems, or robotic arms, this innovative technology ensures smooth and reliable operation, even in the most demanding conditions. What sets the Compensator Joint apart is its unique ability to maintain optimal performance and extend the lifespan of machinery, ultimately leading to cost savings and increased productivity for businesses.The key to the success of the Compensator Joint lies in its meticulous design and rigorous testing. {Company Name} has invested heavily in research and development, collaborating with top engineering experts to create a joint that exceeds industry standards. The company's unwavering commitment to quality and innovation is evident in the robustness and precision of the Compensator Joint, making it a standout choice for businesses looking to elevate their machinery to new heights.But it's not just the superior performance of the Compensator Joint that has garnered attention; it's also the company's dedication to customer satisfaction and support. {Company Name} takes pride in providing comprehensive technical assistance and guidance to ensure that their customers can unleash the full potential of this groundbreaking technology. With a team of skilled engineers and experts, they offer personalized solutions and recommendations tailored to each client's specific needs, further solidifying their reputation as a trusted partner in the industry.The impact of the Compensator Joint is already being felt across various sectors, with businesses reporting significant improvements in operational efficiency and reliability. From manufacturing plants to logistics companies, the adoption of this cutting-edge technology has been a game-changer, setting new benchmarks for performance and quality.Looking ahead, {Company Name} is poised to continue pushing the boundaries of what's possible in the field of industrial engineering. With a strong focus on innovation and a passion for excellence, the company remains committed to developing groundbreaking solutions that empower businesses to thrive in an ever-evolving market.In conclusion, the Compensator Joint is a testament to {Company Name}'s unwavering dedication to redefining industry standards and delivering unparalleled value to its customers. As businesses continue to seek out innovations that can give them a competitive edge, the Compensator Joint stands out as a shining example of what is possible when vision, expertise, and relentless determination come together. With this groundbreaking technology, {Company Name} is not just revolutionizing industrial machinery; they are shaping the future of the industry as a whole.

Insightful Updates Delves into the World of Bellows by Expert Authors - Johnball2014, Exaircorp, and Joe Panfalone

Metallic Bellows Design: Key Considerations for Successful ApplicationsBellows are essential components in many industrial applications, where they provide flexibility, reliability, and durability. Metallic bellows, in particular, offer superior performance in demanding environments where high-pressure, high-temperature, and corrosive fluids are present. However, designing a metallic bellows requires careful consideration of various factors, including material selection, geometry, performance parameters, and manufacturing processes. In this blog, we will explore some key considerations for successful metallic bellows design.Material selection: The choice of material for a metallic bellows depends on the intended application and the operating conditions. Typically, metallic bellows are made of alloys such as stainless steel, Inconel, Hastelloy, or titanium. Stainless steel is the most commonly used material due to its excellent corrosion resistance, thermal stability, and affordability. Inconel and Hastelloy, on the other hand, offer superior resistance to high temperature, acids, and alkalis, making them ideal for critical applications in the chemical, petrochemical, and aerospace industries. Titanium is suitable for applications that require high strength, low weight, and biocompatibility.Geometry: The geometry of a metallic bellows determines its flexibility, pressure capacity, and fatigue life. A typical bellows consists of a series of convolutions that allow it to expand and compress axially, while maintaining a constant volume. The number, pitch, height, and wall thickness of the convolutions influence the bellows' performance parameters, such as stroke, spring rate, and cycle life. Bellows with fewer convolutions have higher stiffness, while those with more convolutions have higher flexibility. Bellows with thicker walls have higher pressure capacity but lower flexibility. The pitch and height of the convolutions determine the bellows' axial stroke and displacement.Performance parameters: The performance parameters of a metallic bellows include stroke, cycle life, pressure capacity, leak tightness, and vibration resistance. Stroke refers to the axial displacement of the bellows under an external load. Cycle life refers to the number of cycles the bellows can withstand before failure due to fatigue. Pressure capacity refers to the maximum pressure the bellows can withstand without permanent deformation or rupture. Leak tightness refers to the bellows' ability to maintain a seal against gas or fluid leakage. Vibration resistance refers to the bellows' ability to withstand dynamic loads without fatigue failure.Manufacturing processes: The manufacturing processes for metallic bellows involve several steps, including cutting, forming, welding, and testing. The cutting process involves trimming the raw material to the correct size and shape. The forming process involves shaping the material into the desired convolution geometry using hydraulic or mechanical dies. The welding process involves joining the convolutions together using either TIG or laser welding. Finally, the testing process involves verifying the bellows' performance parameters using various methods, such as hydrostatic testing, vacuum testing, or fatigue testing.In conclusion, designing a metallic bellows requires careful consideration of various factors, including material selection, geometry, performance parameters, and manufacturing processes. By selecting the appropriate materials, optimizing the geometry, ensuring the desired performance parameters, and using reliable manufacturing processes, you can achieve a successful metallic bellows design that meets your application's specific requirements. At (company name), we specialize in designing and manufacturing high-quality metallic bellows for a wide range of applications, from aerospace and defense to medical and semiconductor. Contact us today to learn more about how we can help you with your metallic bellows design needs.

Durable and Reliable Rubber Connectors for Various Applications

Connector Rubber, a leading player in the rubber manufacturing industry, has been making waves with its innovative products and advanced technology. The company has been successfully serving various industries such as automotive, aerospace, marine, and construction, providing them with top-quality rubber parts and components.Established in the year {}, Connector Rubber has constantly strived to achieve excellence in its products and services. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing them to meet the growing demands of their customers while maintaining high-quality standards.Specializing in the production of various rubber products, Connector Rubber has gained a reputation for its precision in manufacturing and exceptional customer service. With a team of experienced engineers and technicians, the company has the capability to design and develop custom rubber components based on the specific requirements of its clients.One of the key factors that set Connector Rubber apart from its competitors is its relentless focus on research and development. The company has made significant investments in R&D to innovate new materials and manufacturing processes, ensuring that they stay ahead in the ever-evolving rubber industry.Furthermore, Connector Rubber is committed to sustainability and environmental responsibility. The company strictly adheres to eco-friendly manufacturing practices and uses raw materials that are compliant with international standards. Their dedication to sustainability has earned them recognition from various environmental organizations and industry bodies.In a recent development, Connector Rubber has announced the launch of a new range of high-performance rubber connectors that are set to revolutionize the industry. These connectors are designed to offer superior durability, flexibility, and resistance to extreme conditions, making them ideal for a wide range of applications.The new range of rubber connectors is a result of extensive research and development, incorporating the latest advancements in materials and manufacturing techniques. Connector Rubber's team of engineers has worked tirelessly to ensure that the new products meet the highest quality standards and exceed the expectations of their customers."We are extremely excited to introduce our new line of rubber connectors to the market. These products represent the culmination of our efforts to push the boundaries of innovation and deliver exceptional value to our customers," said [Name], CEO of Connector Rubber. "We are confident that these connectors will set new benchmarks in terms of performance and reliability, further solidifying our position as a leading player in the rubber manufacturing industry."The new range of rubber connectors is expected to cater to a wide array of industries, including automotive, aerospace, and manufacturing. With their advanced features and robust construction, these connectors are poised to address the specific needs and challenges faced by different sectors, making them highly sought after in the market.Connector Rubber's dedication to excellence and customer satisfaction has earned them a loyal clientele, with many leading companies preferring their products over others in the market. The company's commitment to delivering top-quality rubber components and its proactive approach to innovation has placed them at the forefront of the industry.As Connector Rubber continues to push the boundaries of rubber manufacturing, it is poised to set new standards in the industry and cement its reputation as a reliable and innovative partner for businesses worldwide. With its cutting-edge technology, unwavering commitment to quality, and focus on sustainability, Connector Rubber is well-positioned to leave a lasting impact on the rubber manufacturing industry for years to come.

Top Quality Metallic Expansion Joints for Industrial Use

[Your Company Name], a leading provider of industrial engineering solutions, has introduced a new line of Metallic Expansion Joints to its product offering. These expansion joints are designed to provide critical flexibility in industrial piping systems, allowing for thermal expansion and vibration isolation in a wide range of applications.The new Metallic Expansion Joints are manufactured with high-quality materials and precision engineering to ensure optimal performance and long-term reliability. The expansion joints are available in a variety of sizes and configurations to accommodate the specific needs of different industries and applications.One of the key features of [Your Company Name]'s Metallic Expansion Joints is their ability to absorb and reduce movement and stress in piping systems, thereby extending the life of the system and reducing the risk of damage or failure. This makes them a critical component in industrial infrastructure for a wide range of sectors, including petrochemical, power generation, marine, and pulp and paper industries.In addition, [Your Company Name]'s expansion joints are designed to withstand high temperatures, corrosive environments, and high-pressure conditions, making them suitable for use in even the most demanding industrial settings. This ensures that they provide reliable and efficient performance, even in the harshest operating conditions.Incorporating Metallic Expansion Joints into industrial piping systems can result in significant cost savings by reducing maintenance and repair costs, minimizing downtime, and extending the service life of the entire system. This can have a direct impact on the overall efficiency and productivity of industrial operations, making them an essential investment for any industrial facility.Furthermore, with a team of experienced engineers and technical specialists, [Your Company Name] is able to provide comprehensive support and guidance to help customers select the right Metallic Expansion Joints for their specific needs. The company offers custom design and engineering services to ensure that the expansion joints are perfectly tailored to the requirements of each individual application.In addition to their high-quality products, [Your Company Name] is committed to providing excellent customer service and support. The company works closely with its customers to understand their unique challenges and requirements, and offers ongoing technical assistance to ensure the optimal performance of its products.[Your Company Name] has established a strong reputation for delivering reliable, high-performance industrial engineering solutions to customers around the world. With a focus on innovation, quality, and customer satisfaction, the company continues to be a trusted partner for industrial organizations seeking to optimize their operations and enhance their infrastructure.As the demand for durable, high-performance industrial components continues to grow, [Your Company Name] is positioned to meet the needs of its customers with its new line of Metallic Expansion Joints. With their exceptional performance, reliability, and versatility, these expansion joints are set to become an essential component in industrial piping systems across a wide range of industries.In conclusion, the introduction of Metallic Expansion Joints by [Your Company Name] represents a significant advancement in the company's product offering. With their ability to provide critical flexibility, absorb movement and stress, and withstand harsh operating conditions, these expansion joints offer a practical and cost-effective solution for a wide range of industrial applications. With [Your Company Name]'s commitment to excellence and customer support, these expansion joints are set to make a positive impact on the efficiency and reliability of industrial operations around the world.