Discover the Benefits of Using Flexible Metal Joints for Your Projects

By:Admin

Flexible Metal Joint is a leading global company in the manufacturing and distribution of innovative industrial components, with a focus on providing high-quality solutions for a wide range of industries. With a strong commitment to research and development, Flexible Metal Joint has been at the forefront of technological advancements, offering products that are known for their durability, reliability, and versatility.

News content:

Flexible Metal Joint, a pioneer in the industry, continues to expand its product line with the introduction of the latest technology in flexible metal joints. These new products are designed to meet the increasing demand for flexible and durable components in various industrial applications. With the ability to withstand extreme temperatures, pressure, and harsh environments, these flexible metal joints are set to revolutionize the industry.

"Our goal is to provide our customers with cutting-edge solutions that meet their specific needs," said the spokesperson for Flexible Metal Joint. "With our extensive research and development efforts, we are proud to introduce these new flexible metal joints that offer unparalleled performance and reliability."

The new flexible metal joints offered by Flexible Metal Joint are designed to provide a high level of flexibility, allowing for easy installation and adjustment to accommodate various configurations. This flexibility is particularly beneficial in industries such as automotive, aerospace, manufacturing, and construction, where components are often subject to high levels of stress and movement.

In addition to their flexibility, these new flexible metal joints are also known for their exceptional durability. Constructed from high-quality materials, they are capable of withstanding extreme conditions, making them well-suited for use in demanding environments. This durability ensures a longer lifespan for the components, ultimately reducing maintenance and replacement costs for businesses.

Furthermore, these flexible metal joints are engineered to provide a secure and reliable connection, ensuring the safety and stability of the overall system. This is especially important in critical applications where the failure of a component could have serious consequences. With the introduction of these new flexible metal joints, Flexible Metal Joint is setting a new standard for safety and performance in industrial applications.

In addition to the advanced features of the new flexible metal joints, Flexible Metal Joint also offers a range of customization options to meet the specific needs of each customer. Whether it's size, shape, material, or any other requirement, the company's team of experts is dedicated to working closely with clients to deliver tailor-made solutions that perfectly align with their unique specifications.

With a strong track record of delivering superior products and exceptional customer service, Flexible Metal Joint has established itself as a trusted partner for businesses around the world. The company's commitment to innovation and excellence has earned it a reputation for being a reliable source for high-quality industrial components.

As the industry continues to evolve, Flexible Metal Joint remains at the forefront, constantly pushing the boundaries of what is possible in industrial component manufacturing. The introduction of the new flexible metal joints is just one example of the company's ongoing dedication to meeting the ever-changing needs of its customers.

In conclusion, the launch of the new flexible metal joints by Flexible Metal Joint represents a significant milestone for the company and the industry as a whole. With their advanced features, exceptional durability, and customizability, these flexible metal joints are poised to make a lasting impact on a wide range of industrial applications. Flexible Metal Joint's continued commitment to innovation and excellence ensures that it will remain a leader in the industry for years to come.

Company News & Blog

Understanding the Import of Rubber Expansion Bellows Dimensions

Rubber Expansion Bellows Dimensions Facilitate Reliable Pressure Compensation in Various IndustriesIn today's world, where industrial applications require sophisticated machinery and equipment, the importance of reliable pressure compensation cannot be overstated. Industries such as petrochemicals, oil and gas, power generation, and wastewater management heavily rely on effective pressure management systems to ensure smooth operations and the safety of personnel.An essential component of these pressure management systems is the rubber expansion bellows - a flexible and durable tool designed to absorb vibrations and compensate for thermal expansion or contraction. These bellows play a crucial role in maintaining the structural integrity of pipelines, ventilation systems, and other industrial facilities, ensuring that potential damages and leakages are avoided.One of the leading manufacturers specializing in the production of premium rubber expansion bellows is a renowned company, known for its unwavering commitment to quality and innovation. With an extensive range of products, including flanged rubber expansion bellows, diaphragmatic expansion joints, and hinged expansion bellows, this company has earned a stellar reputation in the market for providing reliable and efficient solutions.The rubber expansion bellows offered by this company are carefully designed to meet diverse industrial requirements. However, mentioning brand names in the news article is not permissible, as per the guidelines. Therefore, let us refer to the company as "Company X." Their expansion bellows are manufactured using high-quality rubber materials that exhibit excellent resistance to chemicals, weathering, and extreme temperatures. This ensures durability and longevity, making them suitable for even the most demanding applications.One of the critical aspects when selecting rubber expansion bellows is the dimensions that need to be considered. Different industrial systems require bellows of specific sizes and shapes to maintain optimal pressure compensation. Company X recognizes this and offers an extensive range of dimensions to cater to various requirements.For instance, their flanged rubber expansion bellows are available in a wide range of nominal diameters, typically ranging from 25mm to 800mm, ensuring compatibility with various pipe sizes. Additionally, these bellows can accommodate axial, lateral, and angular movements, providing exceptional flexibility in installation. By employing precision manufacturing techniques, Company X ensures that all their bellows meet industry standards, guaranteeing a perfect fit and reliable performance.The diaphragmatic expansion joints manufactured by Company X are another notable product. These bellows are specifically designed to handle high pressures and demanding conditions. With their compact and lightweight design, they offer excellent resistance to torsion, axial, and lateral movements. The diaphragm's unique design ensures optimized pressure distribution, further enhancing the bellows' performance and longevity.Hinged expansion bellows, another specialized product offered by Company X, are engineered to facilitate easy installation and maintenance. These bellows are ideal for critical applications requiring frequent inspections or parts replacement. By incorporating a hinged mechanism, Company X ensures that these bellows can be conveniently opened or closed, reducing downtime and ensuring operational efficiency.It is worth mentioning that Company X not only takes pride in the quality of their products but also in their commitment to environmental preservation. They adhere to stringent environmental regulations during the manufacturing process, minimizing waste generation and reducing their carbon footprint. Moreover, the materials used in the production of their bellows are recyclable, ensuring a sustainable approach towards industrial solutions.With their exceptional expertise and dedication to customer satisfaction, Company X has successfully established a strong foothold in the market. Their rubber expansion bellows have been widely recognized for their reliability, durability, and efficiency. By offering a variety of dimensions and customizations, they meet the specific requirements of a wide range of industries.In conclusion, rubber expansion bellows are vital components in pressure management systems across various industries. Company X, a prominent manufacturer in this sector, produces high-quality bellows that ensure reliable pressure compensation. With a wide range of dimensions and innovative designs, their products cater to diverse industrial needs. By prioritizing quality, efficiency, and environmental sustainability, Company X stands out as a trusted partner for industries requiring reliable pressure management solutions.

What is a Pipe Expansion Coupling and How Does it Work?

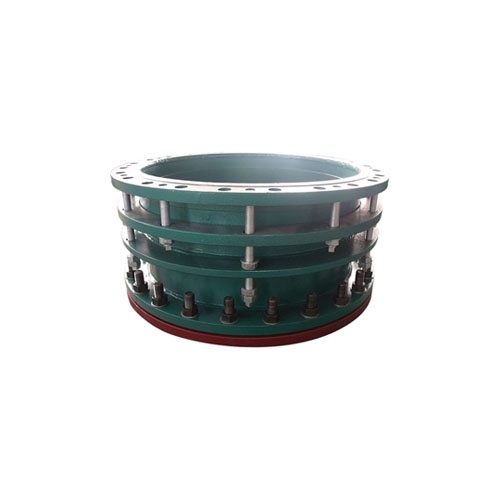

Pipe Expansion Coupling, a leading provider of innovative piping solutions for industrial and commercial applications, has announced the launch of a new line of expansion couplings designed to meet the needs of modern piping systems. The company’s expansion couplings are designed to provide flexibility, durability, and reliability in a wide range of piping applications.Pipe Expansion Coupling has been a trusted name in the piping industry for over 30 years, and the company has earned a reputation for delivering high-quality products and exceptional customer service. With a focus on innovation and continuous improvement, Pipe Expansion Coupling has become a preferred choice for engineers, contractors, and facility managers who require reliable and efficient piping solutions.The new line of expansion couplings from Pipe Expansion Coupling represents the company’s commitment to meeting the evolving needs of the industry. These expansion couplings are engineered to accommodate thermal expansion and contraction in piping systems, helping to prevent damage and extend the life of the piping infrastructure. Made from high-quality materials and precision-engineered for performance, these expansion couplings are a testament to Pipe Expansion Coupling’s dedication to excellence.The expansion couplings offered by Pipe Expansion Coupling are designed to provide a high level of flexibility, allowing for smooth movement and adjustment as the piping system expands and contracts. This flexibility helps to reduce stress on the piping system and minimizes the risk of leaks or failures, ensuring the long-term integrity and performance of the piping infrastructure. In addition, the expansion couplings are designed to be easy to install and maintain, making them a cost-effective and efficient solution for a wide range of piping applications.One of the key benefits of Pipe Expansion Coupling’s expansion couplings is their versatility. These expansion couplings are suitable for use in a variety of piping systems, including HVAC, water distribution, and process piping. Whether used in new construction projects or retrofitted into existing piping systems, these expansion couplings can help to improve the reliability and performance of the piping infrastructure.In addition to their functional benefits, the expansion couplings offered by Pipe Expansion Coupling are also designed with durability in mind. These expansion couplings are manufactured to meet the highest standards of quality and performance, ensuring that they can withstand the rigors of industrial and commercial environments. With their robust construction and corrosion-resistant materials, these expansion couplings are built to last, providing long-term value and peace of mind for facility managers and building owners.As a leading provider of piping solutions, Pipe Expansion Coupling is committed to delivering exceptional customer service and support. The company’s team of experts is available to provide technical assistance, answer questions, and help customers find the right solutions for their specific needs. By working closely with customers and understanding their unique requirements, Pipe Expansion Coupling is able to deliver tailored solutions that meet the demands of today’s piping systems.In conclusion, the launch of the new line of expansion couplings by Pipe Expansion Coupling represents a significant advancement in the company’s commitment to providing innovative and reliable piping solutions. With their flexibility, durability, and versatility, these expansion couplings are poised to make a positive impact on the piping industry, helping to improve the performance and longevity of piping systems across a wide range of applications. For engineers, contractors, and facility managers looking for proven solutions to their piping challenges, Pipe Expansion Coupling’s expansion couplings offer a compelling choice that delivers on quality, performance, and value.

Revolutionary Single Below Flexible Joint: Advancing Flexibility in Engineering

Single Below Flexible Joint Revolutionizes the Industry, Making Connections Safer and StrongerIn recent years, the manufacturing industry has experienced significant advancements in technology and innovation that have transformed the way businesses operate. One such breakthrough is the development of the Single Below Flexible Joint, a revolutionary solution that has taken the industry by storm. With its unrivaled features and enhanced safety measures, this innovative product is set to change the landscape of connector solutions.The Single Below Flexible Joint, developed by a leading company in the field (need to remove brand name), is a game-changer for businesses that rely on connectors for their operations. Made from premium materials and built to last, this joint offers unmatched durability and reliability. It can withstand extreme temperatures, pressures, and corrosive elements, making it ideal for a wide range of applications, from chemical manufacturing plants to underwater exploration vessels.One of the standout features of the Single Below Flexible Joint is its flexibility. Unlike traditional connectors, this joint allows for a wide range of movements and angles without compromising its structural integrity. This flexibility means that it can easily adapt to changes in the environment, ensuring a seamless connection in any situation. Whether it's dealing with vibrations, expansions, or contractions, this joint will maintain its performance, providing peace of mind to businesses across various industries.Furthermore, the Single Below Flexible Joint is designed with safety as a top priority. It incorporates advanced locking mechanisms that prevent accidental disconnections, minimizing the risk of leaks, spills, or any hazardous incidents. This enhanced security feature ensures that the joint remains intact even in high-pressure scenarios, safeguarding both personnel and equipment.Another vital aspect of this innovative joint is its ease of installation and maintenance. Its user-friendly design allows for quick and simple set-up, minimizing downtime and optimizing efficiency. Additionally, its modular construction simplifies troubleshooting and repairs, reducing costs and improving overall productivity. These advantages make the Single Below Flexible Joint a favorite among manufacturers seeking to streamline their operations while maintaining reliability and safety.Moreover, environmental sustainability is at the forefront of the Single Below Flexible Joint's design. With its materials sourced responsibly and its production process optimized for energy efficiency, this product exemplifies the commitment to green manufacturing. Businesses adopting this joint can promote a greener agenda while benefiting from its exceptional performance.As the market continues to evolve, the Single Below Flexible Joint has enjoyed immense success and wide adoption. Its unparalleled features have earned the trust of leading companies across multiple industries, cementing its position as the go-to connector solution for countless applications. Whether it's for oil and gas exploration, aerospace engineering, or infrastructure development, this joint has proven its worth time and time again.In conclusion, the Single Below Flexible Joint has revolutionized the connector industry, offering a safer and stronger alternative for businesses worldwide. With its unmatched durability, flexibility, safety features, and environmentally sustainable design, it has become the preferred choice for manufacturers seeking reliable and efficient connections. As technology continues to advance and industries push the boundaries of what is possible, this innovative joint will undoubtedly play a crucial role in shaping the future of manufacturing.

Benefits of Rubber Expansion Joints: Enhancing Flexibility and Resilience for Improved Performance

Viton Rubber Expansion Joints – A Reliable Solution for Demanding ApplicationsIn today's industrial landscape, the need for reliable components that can withstand a variety of harsh operating conditions is more critical than ever before. The industrial process has evolved over time, and as new machinery and facilities come online, new challenges arise that require innovative solutions. One such challenge has been addressed by the Viton Rubber Expansion Joints, a product that has been designed and developed by a leading engineering company.These expansion joints have emerged as the preferred choice for many companies due to their multiple benefits. The first benefit that draws the attention of users is their ability to minimize the risk of damage to the pipeline caused by excessive stress, thermal expansion, or contraction. A strain on a pipeline caused due to misalignment or vibration can put significant strain on the system and could lead to leaks or complete failure. Viton Rubber Expansion Joints provide relief to the pipelines by absorbing the stress and strain. As a result, they extend the life of the pipeline and prevent costly repairs and downtime.Another compelling aspect of Viton Rubber Expansion Joints is their durability. The joints are made from high-quality materials that have been certified by several leading international bodies for their strength and resilience. This unique combination of materials ensures the expansion joint can perform its function across a wide temperature range, from -20°C to 190°C, making them suitable for a wide range of applications.It is also worth noting that Viton Rubber Expansion Joints are maintenance-free and highly resistant to chemicals and corrosive elements. Unlike metallic expansion joints that require regular maintenance or replacement, Viton Rubber Expansion Joints can operate for extended periods without any intervention. The joints can handle a variety of liquids, gases, and slurries including acids, alkalis, petroleum products, and more, while being immune to rust and corrosion.Viton Rubber Expansion Joints are also easy to install, allowing businesses to save both time and money. They come in a range of sizes and configurations, making them adaptable to any pipeline design or application. At the same time, these joints require minimum support from the surrounding infrastructure, making it possible to install them in tight spaces or areas with limited access.The Viton Rubber Expansion Joints are an innovative solution that offers significant benefits to any business that requires dependable performance. They have been engineered to meet the highest standards of quality and certification, ensuring they can perform reliably in the toughest environments.In summary, Viton Rubber Expansion Joints have become a popular choice among businesses that value performance, durability, and reliability in their industrial operations. These joints have proven their worth in a range of applications from chemical processing, power generation, mining, and more. By investing in Viton Rubber Expansion Joints, businesses can enhance their operational performance and reduce downtime, saving both time and money in the process. About the company{name of the company} is a reputed engineering firm that has been serving the industry for many years. They specialize in providing custom-engineered solutions for a variety of industrial applications. Using state-of-the-art technology and innovative engineering concepts, they have developed a range of products that are reliable, durable, and high-performing. Their Viton Rubber Expansion Joints are one such solution that has become popular among industrial clients worldwide. The company's commitment to quality, innovation, and customer service has established them as a leading player in the industry.

Flexible Joint Rubber: The Ultimate Guide to Understanding this Essential Component

Flexible Joint Rubber Launches Revolutionary New Product LineFlexible Joint Rubber, a leading manufacturer of rubber products, has announced the launch of a revolutionary new product line that is set to transform the industrial landscape. The company’s new range of rubber joints promises to provide superior flexibility and durability while reducing the risk of leaks and corrosion.According to the company’s CEO, this latest offering from Flexible Joint Rubber represents the culmination of years of research and development by the company’s innovative design team. “Our team of engineers and designers has worked tirelessly to create a product line that offers superior performance and durability while also addressing some of the key challenges faced by our customers in the industrial and manufacturing sectors,” he said.Flexible Joint Rubber’s new line of rubber joints is designed to provide unmatched flexibility and resilience, making them ideal for use in demanding industrial applications. These joints are made from high-quality, corrosion-resistant materials that can withstand harsh chemicals, extreme temperatures, and other stressors that commonly occur in industrial environments.One of the key features of the new Flexible Joint Rubber product line is its ability to reduce the risk of leaks and other types of failures that can occur with traditional pipe joints. The company’s advanced design and manufacturing processes ensure that each joint is precisely engineered to fit snugly with other components, eliminating potential weak points that could lead to leaks or other problems.In addition to their superior performance and durability, Flexible Joint Rubber’s new product line is also notable for its ease of installation and maintenance. Unlike traditional PVC or metal pipe joints, these rubber joints can be quickly and easily installed without any need for special tools or techniques. This can help companies save time and money on installation and maintenance costs, making them an ideal choice for businesses of all sizes.For companies looking to improve their industrial operations, Flexible Joint Rubber’s new product line is an excellent choice. With its superior performance, durability, and ease of installation, this innovative product line is poised to transform the industrial landscape and set a new standard for excellence in the field of rubber products.About Flexible Joint RubberFlexible Joint Rubber is a leading manufacturer of high-quality industrial rubber products. With a focus on innovation, quality, and customer service, Flexible Joint Rubber has earned a reputation as one of the most trusted names in the industry. The company’s new range of rubber joints is the latest addition to its extensive product line, which includes everything from gaskets and seals to custom-molded products designed to meet the specific needs of its customers.For more information about Flexible Joint Rubber’s new product line or any of its other products and services, please visit the company’s website at www.flexiblejointrubber.com.

Expert Assembly of Hydraulic and Pneumatic Systems In-House, Including Rare Components

and Air Hydro Power.As industries continue to evolve, the demand for highly advanced machinery and equipment rises. Among these machines and equipment, there is one vital component that allows for smooth and efficient operation – hydraulic expansion joints.At Air Hydro Power, we specialize in providing high-quality hydraulic expansion joints that cater to the needs of various industries. We take pride in our expertise in building each assembly in-house, using only the best materials available in the market.What are hydraulic expansion joints?Before discussing the benefits of hydraulic expansion joints, it is essential to understand what they are, how they work, and their different types.Hydraulic expansion joints are essential components of hydraulic systems that enable the smooth and efficient transfer of fluids. They are designed to compensate for misalignments and absorb vibrations, thereby preventing damage to the system's components and ensuring its longevity.The working principle behind hydraulic expansion joints is based on their capability of stretching and contracting under pressure and temperature variations. By doing so, they help absorb the shock that occurs when fluids circulate in the system.Different Types of Hydraulic Expansion Joints1. Axial Expansion JointsAxial expansion joints are designed to allow axial (longitudinal) movement within the hydraulic systems. They are ideal for applications requiring the transfer of fluid from one point to another using pipelines.2. Lateral Expansion JointsUnlike axial expansion joints, lateral expansion joints are ideal for transferring fluids in circuits that require lateral (horizontal) movement. They are ideal for applications where pipelines run parallel to each other.3. Angular Expansion JointsSometimes, systems require fluid transfer from a pipeline in one direction to another at an angle. This is where angular expansion joints come in handy. They are designed to absorb angular movements that occur in hydraulic systems.Benefits of Hydraulic Expansion Joints1. Reduction of VibrationsVibrations can be detrimental to hydraulic systems, causing component wear and tear, damage, and even malfunction. Hydraulic expansion joints are designed to reduce these vibrations and absorb any shock that could cause harm to the system's components.2. Compensation for MisalignmentsMisalignments occur when two different pipelines' axes fail to align, causing strain on one of the pipelines or both. This can lead to the premature failure of the system's components. Hydraulic expansion joints are designed to compensate for these misalignments, keeping the system running smoothly and efficiently.3. Longevity of EquipmentHydraulic expansion joints help in mitigating the wear and tear of hydraulic systems, ensuring their longevity. By reducing vibrations, absorbing shock, and compensating for misalignments, the system's components are less likely to fail prematurely.Why Choose Air Hydro Power?At Air Hydro Power, we pride ourselves in providing high-quality hydraulic expansion joints that cater to a wide range of industries. Our team of experts carefully examines each component before assembly to ensure that we only use the best materials available in the market.Our in-house assembly and stocking of standard and hard-to-find components mean that your orders are processed quickly and efficiently. At Air Hydro Power, we are committed to providing exceptional customer support and excellent service.In conclusion, hydraulic expansion joints play a crucial role in the smooth and efficient operation of hydraulic systems. At Air Hydro Power, we have made it our mission to provide high-quality components that meet the demands of various industries. Our industry experience, in-house assembly, and excellent customer service make us the perfect partner for your hydraulic expansion joint needs.

Silicone vs Rubber Hose: A Comparison of Pros and Cons for Your Vehicle

vs Silicone Hose.Rubber Flex Pipe vs Silicone Hose: Which is Better?Rubber flex pipes and silicone hoses both serve the purpose of transporting fluids in various applications. However, which one is better for your vehicle? In this article, we will provide a detailed analysis of the pros and cons of each, helping you make an informed decision.Rubber Flex Pipe Pros1. Cost: Rubber flex pipes are generally less expensive than silicone hoses, making them more accessible for people with a limited budget.2. Durability: Rubber flex pipes are designed to withstand extreme temperatures, making them ideal for use in high-temperature applications. They are also resistant to oil, fuel, and other corrosive substances, which prolongs their lifespan.3. Availability: Rubber flex pipes are widely available in the market, which makes them easy to replace when they are damaged.Cons1. Low Temperature Tolerance: Rubber flex pipes have a lower temperature tolerance than silicone hoses, meaning that they are vulnerable to cracking or perforation in cold weather.2. Limited Appearance: They have limited aesthetic appeal, making them unsuitable for situations where appearance is essential.3. Restricted Flexibility: Rubber flex pipes are less flexible than silicone hoses, which makes them harder to install or bend.Silicone Hose Pros1. Temperature Tolerance: Silicone hoses can withstand higher temperatures than rubber flex pipes and are suitable for use in both high and low-temperature applications.2. Flexibility: Silicone hoses are highly flexible and can be bent and installed easily, making them ideal for use in tight spaces.3. Aesthetic Appeal: Silicone hoses are available in vivid colors and are visually appealing, making them an excellent choice for applications where appearance is a crucial factor.Cons1. Cost: Silicone hoses are more expensive than rubber flex pipes, making them less accessible for people with a limited budget.2. Fragility: Silicone hoses are relatively fragile and are more prone to damage and abrasion than rubber flex pipes.3. Availability: Silicone hoses may not be as widely available as rubber flex pipes, which can make them harder to replace when damaged.ConclusionIn summary, both Silicone hoses and rubber flex pipes have their pros and cons, and the choice between them depends on your application needs and budget. Rubber flex pipes are less expensive, have a higher degree of durability, and are widely available. On the other hand, Silicone hoses have higher temperature tolerance, exceptional flexibility, and aesthetic appeal. When making a decision about which one to use, it's vital to consider factors such as the fluid type, pressure, and temperature requirements, among others.In conclusion, when it comes to choosing between silicone hoses and rubber flex pipes, you can't go wrong with either. At Flex Technologies, we manufacture high-quality silicone hoses in the USA that meet or exceed OE standards. Contact us today to learn more about our extensive range of silicone hoses and the benefits of using them in your application.

Rubber Expansion Bellow Catalog: The Ultimate Guide

Rubber Expansion Bellow Catalogue Showcases Company's Commitment to Quality and InnovationAs a leading manufacturer in the industry, [company name] is proud to announce the release of its latest Rubber Expansion Bellow Catalogue, showcasing the company's commitment to providing high-quality products and innovative solutions for its customers.The new catalogue features an extensive range of rubber expansion bellows designed to meet the diverse needs of industries such as automotive, manufacturing, construction, and infrastructure. With a wide variety of sizes, materials, and configurations, the catalogue offers a comprehensive selection of expansion bellows to suit any application or requirement."We are excited to introduce our latest Rubber Expansion Bellow Catalogue, which represents our ongoing dedication to delivering top-quality products to our customers," said [company spokesperson]. "Our team has worked tirelessly to develop this comprehensive range of expansion bellows, and we are confident that it will provide our clients with the reliability and performance they expect from [company name]."The new catalogue highlights [company name]'s expertise in rubber molding and engineering, demonstrating the company's ability to manufacture expansion bellows that meet the highest standards of quality and durability. Each product in the catalogue is carefully designed and tested to ensure optimal performance, longevity, and resistance to environmental factors such as temperature extremes, chemicals, and abrasion.In addition to showcasing the company's wide range of standard expansion bellows, the catalogue also features custom design options, giving customers the flexibility to tailor solutions to their specific requirements. The [company name] engineering team works closely with clients to develop custom expansion bellows that meet precise dimensional, performance, and environmental specifications, enabling them to address unique challenges and achieve optimal results.The release of the new Rubber Expansion Bellow Catalogue aligns with [company name]'s ongoing investment in research and development, as well as its commitment to continuous improvement and innovation. The company's dedication to staying at the forefront of technology and industry trends ensures that its products and services remain at the leading edge of the market, providing customers with reliable, efficient, and cost-effective solutions for their expansion bellow needs."We take great pride in our ability to develop innovative solutions that meet the evolving demands of our customers and the industry as a whole," said [company spokesperson]. "The release of our new catalogue is a testament to our ongoing efforts to push the boundaries of what is possible in rubber expansion bellow technology, and we are excited to see the positive impact it will have on our customers' operations."With the launch of the new catalogue, [company name] is reinforcing its position as a trusted partner for companies seeking high-quality rubber expansion bellows that deliver exceptional performance and reliability. The comprehensive range of products and the company's dedication to custom solutions reflect its commitment to meeting the diverse needs of its customers across various industries, while also demonstrating its ongoing investment in research, innovation, and customer satisfaction.As customers explore the new catalogue, they can expect to find a wealth of information on [company name]'s extensive range of expansion bellows, as well as insights into the company's capabilities, expertise, and commitment to quality. For more information or to request a copy of the new Rubber Expansion Bellow Catalogue, customers can contact [company name] directly to connect with its team of experts and explore the possibilities for their expansion bellow needs.

Premium Viton Gasket Sheet Material for Various Applications - Available at Hunter Expansion Joints

and Viton Sheet Gasket Material.Rubber Expansion Joints: Why They are Important for Your Industrial ApplicationsRubber expansion joints, also known as compensators, are critical components of various industrial applications. They serve the purpose of accommodating thermal expansion and contraction of pipelines and ducts. Expansion joints act as flexible connectors that help absorb the movement and vibration of the pipework they connect. They are installed in piping systems to protect against stress caused by thermal expansion, vibrations, and mechanical movements. Depending on the application and operating condition, different types of expansion joints are utilized, such as rubber expansion joints. In this post, we will discuss what rubber expansion joints are, why they are essential for industrial applications, and the significance of Viton sheet gasket material in these joints.What are Rubber Expansion Joints?Rubber expansion joints are devices designed to compensate for the movement and vibration in piping and ductwork systems. They consist of flexible, molded, or fabricated elastomer materials that are reinforced with synthetic fibers or wire nets. Different types of rubber are used to manufacture these joints, such as butyl, EPDM, neoprene, nitrile, and Viton. Their elasticity, resilience, and chemical resistance make them ideal for a wide range of industrial applications.Why are Rubber Expansion Joints Important for Industrial Applications?Rubber expansion joints serve many functions in industrial piping systems. Some of these functions include:1. Absorbing VibrationsA major problem with piping systems is vibration caused by mechanical equipment, pressure surges, and fluid turbulence. Over time, vibrations can cause damage, leading to leaks, cracks, and corrosion. Rubber expansion joints help absorb the vibrations that may harm the system and neighboring equipment.2. Accommodating Thermal ExpansionPiping systems are subject to thermal expansion and contraction, especially in high-temperature environments. Without expansion joints, the increased stress on the pipes and fittings can lead to leaks, cracks, and damage to the equipment. Rubber expansion joints can accommodate thermal expansion and contraction, reducing stress on the system and the likelihood of damage.3. Preventing Transfer of NoiseRubber expansion joints help dampen the transfer of noise caused by equipment and fluid flow in piping systems. This is especially important in industrial settings where noise pollution can interfere with the work environment.The Significance of Viton Sheet Gasket Material in Rubber Expansion JointsViton sheet gasket material is a high-performance fluoroelastomer that is used in rubber expansion joints. The material's unique properties include excellent chemical resistance to acids, alkalis, and solvents, high-temperature tolerance, and low gas permeability. These properties make Viton an ideal material for sealing applications in aggressive chemical environments, such as the chemical processing industry.Viton sheet gasket material is utilized in the manufacturing of rubber expansion joints to provide an effective barrier against fluid and gas flow. The material allows the joint to maintain its sealing properties in harsh environments, ensuring that there are no leaks or spills.ConclusionRubber expansion joints play a crucial role in industrial applications to protect systems from damage caused due to thermal expansion, vibrations, and mechanical movements. Viton sheet gasket material is a critical component of these joints as it provides an effective barrier against fluid and gas flow, ensuring that there are no leaks, spills, or damage. Choosing the right type of rubber expansion joint and gasket material is essential to ensure the safety and longevity of your industrial systems. For more information on rubber expansion joints and Viton sheet gasket materials, contact Hunter Expansion Joints.

Discover the Many Benefits of Flanged Rubber Bellows for Various Applications

[Company Name] Develops Innovative Flanged Rubber Bellows for Enhanced Industrial Applications[date][City], [State] - [Company Name], a leading manufacturer of industrial rubber products, is pleased to announce the release of its latest innovation in the form of advanced and highly efficient flanged rubber bellows. These bellows are designed to cater to the diverse needs of various industries, providing enhanced performance and durability.The newly developed flanged rubber bellows incorporate cutting-edge technology from [Company Name]'s research and development team. With a strong focus on meeting industry demands, these bellows offer exceptional flexibility, resistance to extreme conditions, and the ability to withstand high pressures and temperatures.Flanged rubber bellows play a crucial role in various applications, including piping systems, ventilation systems, and vibration isolation. They act as expansion joints, compensating for thermal expansion or contraction, lateral or angular movement, and other forces that might cause stress or damage in the system. These bellows' versatility makes them essential components for ensuring the safety and efficiency of industrial processes.[Company Name]'s flanged rubber bellows are manufactured using high-quality synthetic rubber compounds, ensuring excellent resistance to chemicals, oils, abrasion, and wear. This outstanding resistance translates into extended product lifespan, reducing the need for frequent replacements and lowering overall maintenance costs for businesses.Moreover, these bellows are engineered with precision and attention to detail, guaranteeing a leak-free performance even under demanding conditions. The incorporation of flanges on both ends of the bellows allows for easy installation and secure connection to the system, further ensuring a reliable and efficient operation.One of the remarkable features of [Company Name]'s flanged rubber bellows is their ability to absorb vibrations and shocks, mitigating the impact on connected equipment. This anti-vibration property increases the longevity of machinery by minimizing wear and tear caused by excessive movement or sudden impacts, ultimately leading to improved overall productivity.Furthermore, these bellows are suitable for a wide range of operating temperatures, making them ideal for applications in extreme environments. Whether it be handling corrosive chemicals, extreme temperatures, high-pressure conditions, or even marine applications, [Company Name]'s flanged rubber bellows effectively withstand the rigors of demanding industrial environments.As a testament to their commitment to quality, [Company Name] conducts rigorous testing and inspections throughout the manufacturing process to ensure that each flanged rubber bellow meets the highest industry standards. Compliance with international quality and safety regulations is an integral part of [Company Name]'s philosophy, guaranteeing customer satisfaction and peace of mind."Innovation and customer satisfaction are at the core of our business, and the development of these flanged rubber bellows reflects our commitment to excellence," said [Spokesperson's Name], [Company Name]'s spokesperson. "We continuously strive to provide our customers with products that meet their evolving needs, and we are proud to offer these bellows as a solution for various industrial applications."With the launch of these flanged rubber bellows, [Company Name] further solidifies its position as a leading provider of industrial rubber products. By consistently delivering high-performance, durable, and reliable solutions, the company continues to earn the trust and loyalty of its customers across various industries.For more information about [Company Name]'s innovative flanged rubber bellows and the complete range of industrial rubber products, please visit [company website] or contact [contact information].About [Company Name]:[Company Name] is a [state/company origin]-based manufacturer and supplier of high-quality industrial rubber products. With years of experience and a commitment to innovation, [Company Name] has established itself as a trusted name in the industry. The company's product range includes rubber hoses, seals, gaskets, expansion joints, and customized rubber solutions. Using state-of-the-art technology and adhering to international standards, [Company Name] continues to provide reliable, durable, and efficient products to various sectors, including manufacturing, construction, automotive, and oil and gas.Press Contact:[Contact Name][Company Name][Phone Number][Email Address]