Discover the Benefits of Flexible Joint Couplings for Industrial Applications

By:Admin

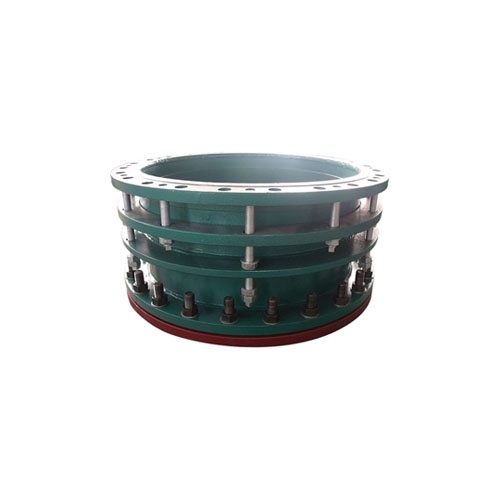

[City, State] - [Company Name], a leading provider of innovative engineering solutions, is proud to introduce its latest product: the Flexible Joint Coupling. This revolutionary coupling is designed to provide enhanced flexibility and reduce misalignment in various industrial applications, resulting in improved overall performance and longevity.

The [Company Name] Flexible Joint Coupling is a key component in a wide range of machinery and equipment, including pumps, compressors, and other rotating systems. Its unique design allows for radial, angular, and axial misalignment, effectively reducing the stress on connected equipment and extending its lifespan. This makes it an ideal solution for industries such as manufacturing, oil and gas, power generation, and more.

"We are thrilled to unveil our Flexible Joint Coupling, which has been engineered to meet the growing demand for reliable and durable coupling solutions in the industrial sector," said [Spokesperson Name], [Title] at [Company Name]. "With its advanced design and superior performance, we believe this product will set a new standard for coupling technology and greatly benefit our customers."

The [Company Name] Flexible Joint Coupling features a high-strength, corrosion-resistant construction, making it suitable for use in even the most demanding environments. Its flexibility allows for easy installation and maintenance, reducing downtime and operational costs for end users. In addition, the coupling is designed to dampen vibrations and minimize noise, creating a safer and more comfortable working environment for operators.

Incorporating the latest advancements in materials and manufacturing techniques, the Flexible Joint Coupling is built to withstand the rigors of continuous operation, even in extreme conditions. Its robust design and performance capabilities make it a reliable solution for a wide range of industrial applications, providing peace of mind for customers who depend on uninterrupted production and operation.

To ensure the highest quality and performance, each [Company Name] Flexible Joint Coupling undergoes rigorous testing and quality control measures before being shipped to customers. This commitment to excellence is a cornerstone of [Company Name]'s reputation as a trusted provider of engineering solutions, and one that customers have come to rely on.

"Our team is dedicated to delivering products that exceed the expectations of our customers, and the Flexible Joint Coupling is a testament to that commitment," added [Spokesperson Name]. "We have seen firsthand the positive impact that this product can have on our customers' operations, and we are excited to bring it to market."

As [Company Name] continues to expand its portfolio of innovative engineering solutions, the introduction of the Flexible Joint Coupling reaffirms the company's dedication to addressing the evolving needs of the industrial sector. With a focus on performance, reliability, and customer satisfaction, [Company Name] is poised to remain a leader in providing cutting-edge technologies for years to come.

For more information about the [Company Name] Flexible Joint Coupling and other engineering solutions, please visit [company website] or contact [company email] for inquiries and assistance.

About [Company Name]:

[Company Name] is a leading provider of innovative engineering solutions for a wide range of industrial applications. With a focus on performance, reliability, and customer satisfaction, [Company Name] is dedicated to delivering products that exceed the expectations of its customers. For more information, please visit [company website].

Company News & Blog

Durable Neoprene Rubber Bellows: A Reliable Solution for Industrial Applications

Neoprene Rubber Bellows, combined with the company introduction, is a key player in the rubber industry, specializing in the manufacturing and distribution of high-quality rubber products globally. The company has been at the forefront of providing top-notch solutions for various industrial applications and has gained a solid reputation for delivering products that meet the highest standards of quality and durability.Neoprene Rubber Bellows has been relentless in its pursuit of excellence, and this has been evident in the range of products it offers, particularly its neoprene rubber bellows. These bellows are designed to provide exceptional protection for moving parts and sensitive components in various machinery and equipment. The company's neoprene rubber bellows are known for their outstanding flexibility, resistance to abrasion, oils, and other harsh chemicals, as well as their ability to withstand extreme temperatures, making them suitable for use in a wide range of industrial environments.In addition to their exceptional physical properties, Neoprene Rubber Bellows' products are also designed to meet the specific needs of its customers. The company takes pride in its ability to work closely with clients to develop custom solutions that address unique challenges and applications. This customer-centric approach has been instrumental in helping Neoprene Rubber Bellows build long-term relationships with its clients and establish its position as a trusted partner in the industry.With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Neoprene Rubber Bellows has the capability to produce bespoke rubber bellows that meet the most demanding requirements. The company's commitment to innovation and continuous improvement has enabled it to stay ahead of the curve and provide cutting-edge solutions that keep up with the evolving needs of modern industries.Neoprene Rubber Bellows' dedication to quality and reliability is further underscored by its adherence to stringent industry standards and regulations. The company places a strong emphasis on quality control at every stage of the manufacturing process, ensuring that each product that leaves its facility is of the highest quality and consistency. This commitment to excellence has earned Neoprene Rubber Bellows the trust and confidence of its customers, who rely on the company's products to keep their operations running smoothly and efficiently.Furthermore, Neoprene Rubber Bellows is not just a supplier of rubber products; it is a partner that is fully committed to the success of its clients. The company offers comprehensive technical support and guidance to help customers select the right products for their specific applications. Whether it's providing recommendations for material selection, design optimizations, or troubleshooting technical issues, Neoprene Rubber Bellows is always ready to go the extra mile to ensure its customers' satisfaction.Finally, Neoprene Rubber Bellows is also dedicated to environmental sustainability and responsibility. The company places a strong emphasis on minimizing its environmental impact by employing eco-friendly manufacturing processes and using recyclable materials whenever possible. Neoprene Rubber Bellows understands the importance of not only delivering top-quality products but also doing so in a way that is mindful of the planet and future generations.In conclusion, Neoprene Rubber Bellows has clearly established itself as a leader in the rubber industry, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. As the company continues to expand its product range and reach new markets, it is set to further solidify its position as a trusted partner for businesses across various industries. With its focus on delivering exceptional products and unparalleled service, Neoprene Rubber Bellows is poised to remain at the forefront of the rubber industry for years to come.

Thermal Expansion Joints: Understanding Their Importance and Applications

Thermal Expansion Bellows Offer Innovative Solutions in Industrial ApplicationsThermal expansion is an inherent property of many materials, and its effects can be seen in various industries. To counteract the potential damages caused by thermal expansion, companies often rely on innovative technologies such as thermal expansion bellows. These sophisticated devices help mitigate the adverse effects of expansion and contraction, ensuring the longevity and efficiency of industrial systems. One notable manufacturer in this industry is an esteemed company that has been revolutionizing the sector with its cutting-edge thermal expansion bellows solutions.Founded in {insert year}, this company has been a pioneer in the field of thermal expansion bellows. With a commitment to quality, innovation, and customer satisfaction, the company has garnered an excellent reputation in various industries. Their comprehensive range of thermal expansion bellows caters to the unique requirements of different applications, providing effective and reliable solutions to address the challenges posed by thermal expansion.The company's thermal expansion bellows are known for their exceptional performance and durability. Engineered using state-of-the-art technology and high-quality materials, these bellows can withstand extreme temperatures, pressure differentials, and corrosive environments. This ensures their longevity and reliability in even the most demanding working conditions. By incorporating advanced design and manufacturing techniques, the company ensures that their bellows offer precise movement, minimal friction, and accurate compensation for thermal expansion, allowing systems to maintain their optimal performance.The applications of thermal expansion bellows are vast and varied. They find extensive usage in industries such as power generation, oil and gas, petrochemicals, aerospace, automotive, and many more. In power generation, for instance, thermal expansion bellows are employed in turbines, heat exchangers, and piping systems to compensate for the expansion and contraction of materials due to temperature fluctuations. By accommodating these movements, the bellows prevent excessive stress and fatigue on system components, minimizing the risk of damage and enhancing the overall efficiency and lifespan of the equipment.Moreover, in the oil and gas industry, thermal expansion bellows play a vital role in piping systems and refineries. With the ability to resist high pressures, extreme temperatures, and corrosive mediums, the bellows ensure the reliability and safety of critical infrastructure. By accommodating thermal expansion and preventing leakage or failure, they contribute to the seamless operation of essential processes, preventing costly downtime and hazardous situations.One key aspect that sets this company apart from its competitors is its ability to provide tailor-made solutions. Understanding that each industry and application has unique demands, the company offers a comprehensive range of customizable bellows. Their team of experienced engineers works closely with clients to understand their specific requirements and design bellows that precisely cater to their needs. From material selection to shape and size, the company ensures that every aspect of the thermal expansion bellows aligns with the customer's specifications, thus maximizing efficiency and performance.Apart from their product excellence, the company prioritizes customer satisfaction by providing exceptional pre and post-sale services. Their dedicated support team assists clients throughout the entire process, from initial consultation to installation and maintenance. With a strong emphasis on communication and collaboration, the company ensures that customers receive prompt responses and tailored assistance for their unique challenges.In a rapidly evolving world, thermal expansion bellows have become indispensable in many industries. With the commitment to innovation, quality, and customer-centric solutions, this company continues to lead the way in providing state-of-the-art thermal expansion bellows. By addressing the challenges posed by thermal expansion, their bellows contribute to the seamless operation, longevity, and efficiency of industrial systems, enabling companies to thrive in competitive markets.

Durable and Reliable 2 Inch Flexible Joint for Industrial Use

Flexible Joint 2 Inch Innovations Drive the Future of Industrial PipingIndustrial piping systems are constantly evolving to improve efficiency, safety, and sustainability. One of the key components of these systems is the flexible joint, which allows for movement and flexibility, especially in applications where vibrations, thermal expansion, or settlement may occur. The latest innovation in the world of industrial piping is the development of the 2 inch flexible joint by a leading company in the field.As a global leader in industrial piping solutions, [Company Name] has always been at the forefront of innovation. With a legacy that spans decades, the company has consistently pushed the boundaries of what is possible in industrial piping, and the new 2 inch flexible joint is a testament to their commitment to excellence and continuous improvement.The 2 inch flexible joint is a game-changer in the industry, offering unparalleled flexibility and durability. Its compact size makes it ideal for a wide range of applications, from small-scale installations to large industrial complexes. The design of the joint allows for easy installation and maintenance, saving time and reducing the risk of downtime for businesses.One of the key features of the 2 inch flexible joint is its ability to absorb movements and vibrations, which helps to protect the integrity of the piping system and reduce the risk of leaks or other issues. This is particularly important in industries where smooth and consistent operation is critical, such as the oil and gas, chemical, and power generation sectors.In addition to its functional benefits, the 2 inch flexible joint is also designed with sustainability in mind. By reducing the need for repairs and replacements, it helps to minimize the environmental impact of industrial operations. Furthermore, its durable construction ensures a long service life, further contributing to its eco-friendly profile.[Company Name] has a long history of developing innovative solutions for industrial piping, and the 2 inch flexible joint is just the latest example of their commitment to driving the future of the industry. The company's dedication to research and development, as well as their focus on customer satisfaction, has made them a trusted partner for businesses around the world.The 2 inch flexible joint is the result of extensive research and engineering expertise, combined with a deep understanding of the needs and challenges faced by the industry. As a result, it is not only a cutting-edge product, but also a solution that addresses real-world issues and provides tangible benefits to businesses.With the launch of the 2 inch flexible joint, [Company Name] has once again demonstrated their leadership in the field of industrial piping. By combining innovation, quality, and sustainability, they have set a new standard for what is possible in industrial piping systems, and have positioned themselves as the go-to partner for businesses looking to optimize their operations.As industries continue to evolve and adapt to new challenges, the need for reliable and efficient piping solutions will only grow. The 2 inch flexible joint is a clear example of how innovation can drive progress in this area, and [Company Name] is proud to be at the forefront of this movement.In conclusion, the 2 inch flexible joint represents a significant step forward in the world of industrial piping, offering unparalleled flexibility, durability, and sustainability. With its compact design, advanced features, and environmentally-friendly profile, it is poised to become a key component in industrial operations around the world. [Company Name]'s dedication to innovation and excellence has once again resulted in a product that sets new standards and helps to shape the future of industrial piping.

Free PNG and SVG Pipe Joint Illustrations and Vector Images in 45 Styles

Pipes are an essential part of our everyday life, from carrying water to transporting gas. However, these pipes cannot function without joints that connect them together. Joints for pipes come in various shapes and sizes, and they are essential for the seamless functioning of our plumbing systems.One common type of joint for pipes is the clip joint. A clip joint is a joining method that involves using a clip or clamp to secure two pieces of pipe together. Clip joints are easy to install and do not require any special tools or expertise. They are commonly used in household plumbing applications such as sink and shower installations.Clip joints come in various materials, including PVC, copper, and stainless steel. These materials are chosen based on the application and the environment in which the joint will be used. For example, PVC clip joints are suitable for low-pressure applications such as drainage systems, while stainless steel clip joints are ideal for high-pressure applications such as gas pipelines.To ensure the proper functioning of clip joints, it is crucial to choose the right size and type of clip for the pipe. Improperly sized or mismatched clips can result in leaks, which can lead to water damage and flooding. It is also important to use high-quality clips from reputable manufacturers to ensure durability and longevity.When installing clip joints, it is essential to follow proper installation procedures. This includes ensuring that the pipes are clean and dry, and that the clip is tightened to the manufacturer's specifications. Failure to follow proper installation procedures can result in leaks, which can compromise the overall integrity of the plumbing system.In summary, joints for pipes, such as clip joints, are essential for the proper functioning of our plumbing systems. It is crucial to choose the right size and type of clip for the pipe and to follow proper installation procedures. With the right joints and installation techniques, we can ensure the seamless functioning of our plumbing systems and avoid water damage and other plumbing issues.Keywords: Joints for Pipes, Clip joints, PVC clip joints, Copper clip joints, Stainless steel clip joints, Plumbing systems, Pipe Joint Clipart Illustrations & Images, PNG, SVG.

The Importance of Double Bellows Expansion Joints in Industrial Applications

Title: Superior Engineering Innovation in Expanding Applications for Bellows Expansion Joints Introduction:In today's competitive market, industries rely on advanced technology and innovative solutions to optimize performance and reduce operational costs. As a leading provider of high-quality engineering solutions, we are proud to introduce our revolutionary Double Bellows Expansion Joint. (Remove brand name) Company has achieved a groundbreaking milestone with this cutting-edge product, revolutionizing the way industries approach expansion joint applications. Body:1. Understanding Expansion Joints: Expansion joints are crucial components used in piping systems to compensate for thermal expansion, vibrations, and misalignment. They play a pivotal role in maintaining system integrity, reducing stress on pipelines, and preventing potential damage or leakage.2. The Evolution of Double Bellows Expansion Joint: Traditionally, single bellows expansion joints have been widely used across industries. However, this design has limitations in addressing complex applications that demand even greater flexibility and reliability. Recognizing this necessity, our engineers have developed an innovative solution – the Double Bellows Expansion Joint.3. Advanced Features and Benefits:Our Double Bellows Expansion Joint offers several key advantages:a) Extended Flexibility: The double bellows configuration enables enhanced axial, lateral, and angular movements, accommodating even the most challenging expansions and contractions within a system. This flexibility significantly reduces stress and prolongs the lifespan of pipelines or ducting.b) Improved Pressure Resistance: The double-layered bellows construction allows for increased pressure resistance, ensuring the joint can withstand demanding operating conditions.c) Vibration and Noise Dampening: With its superior design, the double bellows expansion joint minimizes vibrations, noise transmission, and system shocks, creating a more stable and safer working environment.d) Leak Prevention: The unique design and high-quality materials used in our expansion joint minimize leakage, preventing the loss of valuable resources and reducing the risk of environmental contamination.e) Easy Maintenance and Installation: Our expansion joint design simplifies maintenance procedures, reducing downtime and associated costs. Additionally, the joint's compact size facilitates easy installation, providing convenience to industries across various sectors.4. Extensive Applications:The Double Bellows Expansion Joint finds applications in multiple industries, including but not limited to:a) Chemical and Petrochemical: Used in piping systems handling corrosive substances, such as acids, alcohols, and hydrocarbons.b) Power Generation: Facilitates thermal expansion and contraction in steam and gas pipelines within power plants.c) Oil and Gas: Supports the transportation and distribution of crude oil, natural gas, and refined petroleum products, adapting to various temperatures and pressures.d) HVAC Systems: Enables the smooth operation of heating, ventilation, and air conditioning systems, addressing thermal expansion and shock absorption.e) Water Treatment: Plays a vital role in efficiently managing pipes and duct networks, compensating for temperature changes and reducing stress on infrastructure.5. Quality Assurance and Certifications:Our Double Bellows Expansion Joints undergo rigorous testing to ensure unparalleled performance, reliability, and safety. Our commitment to quality is reflected in multiple certifications such as ISO 9001:2015, ASME Section VIII Division 1, EJMA, and PED 2014/68/EU, assuring customers of our adherence to international standards.Conclusion:The introduction of the Double Bellows Expansion Joint signifies a remarkable advancement in engineering solutions, providing industries with a robust and versatile tool to address the ever-evolving demands of complex applications. (Remove brand name) Company is proud to present this innovative product, further solidifying our position as a leader in providing high-quality and reliable engineering solutions to industries worldwide.

Advantages of Flexible Connector Flange Type in Pipeline Systems

Flexible Connector Flange Type has been a leading player in the industrial connectors market for over a decade now. The company has constantly strived to push the boundaries of innovation and technology, ensuring that its products are of the highest quality and reliability. With a strong focus on customer satisfaction and a commitment to delivering top-notch solutions, Flexible Connector Flange Type has carved a niche for itself in the industry.The Flexible Connector Flange Type connectors are known for their versatility and flexibility, offering a wide range of customization options to meet the specific needs of its customers. Whether it's a standard application or a complex, unique requirement, Flexible Connector Flange Type has the expertise and capabilities to deliver tailor-made solutions that fit the bill perfectly.One of the key products in the Flexible Connector Flange Type portfolio is the flange type connector, which has gained a reputation for its robust design, superior performance, and longevity. The flange type connector is designed to provide a secure and reliable connection between two components, ensuring that there is no compromise on the integrity of the system. With a wide variety of sizes and configurations available, customers have the freedom to choose the exact specifications that best suit their application. This level of flexibility and customization has set Flexible Connector Flange Type apart from its competitors, making it the go-to choice for many industrial customers.In addition to the product itself, Flexible Connector Flange Type also places a strong emphasis on customer support and service. The company has a team of highly skilled and experienced professionals who are dedicated to understanding the unique requirements of each customer and providing them with the best possible solutions. From the initial consultation to the final installation and support, Flexible Connector Flange Type is committed to ensuring a seamless and hassle-free experience for its customers.The success of Flexible Connector Flange Type can be attributed to its unwavering commitment to quality, reliability, and innovation. The company is constantly investing in research and development to stay ahead of the curve and bring cutting-edge solutions to the market. This forward-thinking approach has enabled Flexible Connector Flange Type to stay at the forefront of the industry and continue to set new benchmarks for excellence.With an eye on the future, Flexible Connector Flange Type is gearing up to further expand its product line and reach new markets. The company is poised to leverage its existing strengths and capabilities to cater to the evolving needs of its customers, and stay ahead of the competition. With a strong focus on sustainable growth and customer satisfaction, Flexible Connector Flange Type is well-positioned to maintain its leadership position in the industrial connectors market for years to come.

High-Temperature Expansion Joints with Abrasion-Resistant Inner Sleeves

- Codinor Expansion Joint - Abrasive Products - Altcrom 800Expansion Joint for High Temperature and Abrasive Product – CodinorCodinor is a leading manufacturer of expansion joints that cater to various industrial requirements. The company's expertise lies in designing and manufacturing custom-made expansion joints that can withstand the most challenging environments. Recently, Codinor has designed, manufactured and supplied an expansion joint that can sustain a very high temperature and handle abrasive products, precisely what industries of today require.Industries often demand expansion joints that can withstand high temperatures and handle abrasive products. Codinor has designed and manufactured an expansion joint that caters to these specific requirements of industries. With its innovative design and advanced materials, Codinor has tackled this challenge successfully. The expansion joint designed by the company is equipped with an inner sleeve coated with Altcrom 800 material, which offers an outstanding resistance to corrosion, wear, and tear. The inner sleeve's coating of Altcrom 800 material has enabled the expansion joint to withstand temperatures of up to 1100°C with ease.This expansion joint designed by Codinor is ideal for use in various industries, including the cement, steel, and petrochemical industries. These industries require a high-temperature expansion joint that can cope with abrasive products such as clinker, slag, ash, and other similar materials. The expansion joint's unique design allows for the safe transportation of these materials without causing any damage to the joint or the surrounding equipment.The Codinor expansion joint is also equipped with protection features that enhance the product's durability and longevity. For example, the expansion joint comes with a metal frame that protects the joint from any external impact. The metal frame also ensures that the expansion joint is installed securely, avoiding any misalignments or malfunctions. Additionally, the expansion joint is equipped with bolts that allow for easy installation and removal, making maintenance and replacement more convenient for operators.In conclusion, Codinor's expansion joint designed for high temperature and abrasive products is an innovative and advanced product that caters to the specific requirements of various industries. With its unique design and advanced material coating, this expansion joint can withstand high temperatures and handle abrasive products with ease. The product has undergone rigorous testing to ensure its quality, making Codinor's expansion joint the most reliable and durable choice for industries such as cement, steel, and petrochemical. Codinor's expertise and experience in designing and manufacturing expansion joints make them the ideal partner for industries looking for innovative solutions.

Effective Sealing Systems for Pipe-to-Manhole and Pipe-to-Pipe Connections

Title: Innovative Connector Sealing Systems Revolutionize Pipe-to-Manhole and Pipe-to-Pipe ConnectionsIntroduction:The growth of urban infrastructure and the need for efficient wastewater management have led to an increased demand for reliable and durable pipe connectors. Recognizing this, Rubber Pipe Connectors has introduced pioneer connector sealing systems that aim to revolutionize pipe-to-manhole and pipe-to-pipe connections. These innovative solutions ensure seamless integration, improve performance, and enhance the overall efficiency of wastewater management systems.Connector Sealing Systems:1. Pipe-to-Manhole Connector Sealing Systems:Rubber Pipe Connectors has developed a cutting-edge range of connector sealing systems designed specifically for pipe-to-manhole connections. These connectors provide an air and watertight seal, preventing leakage and minimizing the risk of contamination. By eliminating the possibility of seepage, these sealing systems contribute to a healthier environment and a safer infrastructure.Utilizing the latest materials and manufacturing techniques, these connectors ensure easy installation, enhanced durability, and reduced maintenance requirements. The precisely engineered design of the connectors ensures a secure and long-lasting connection, even under demanding conditions.2. Pipe-to-Pipe Connector Sealing Systems:In addition to pipe-to-manhole connections, Rubber Pipe Connectors offers an exceptional range of connector sealing systems for pipe-to-pipe connections. These connectors facilitate the efficient flow of wastewater between different pipe sections and ensure a reliable and leak-free transition.Rubber Pipe Connectors' pipe-to-pipe sealing systems are tailored to accommodate various pipe sizes and materials commonly used in wastewater management. Their flexibility allows for easy installation and adaptability, minimizing the need for costly alterations or replacements. These connectors simplify the maintenance process and contribute to the longevity of the entire piping system.Advantages of Rubber Pipe Connectors' Sealing Systems:1. Enhanced Performance: Rubber Pipe Connectors' sealing systems ensure a secure and reliable connection that mitigates the risk of leaks, seepage, and potential contamination. By maintaining the integrity of the system, these connectors contribute to a more efficient wastewater management process.2. Durability: The cutting-edge materials and manufacturing techniques employed by Rubber Pipe Connectors guarantee the longevity and durability of their sealing systems. Withstanding the test of time and demanding operational conditions, these connectors reduce the need for frequent replacements or maintenance.3. Easy Installation and Adaptability: Rubber Pipe Connectors' sealing systems are designed with easy installation in mind, significantly reducing downtime during system installation or repairs. Their adaptability to various pipe sizes and materials simplifies the connection process, streamlining the overall operation.4. Cost-Effectiveness: By providing reliable and leak-free connections, Rubber Pipe Connectors' sealing systems minimize the occurrence of costly repairs and potential damage caused by leakage. The durability and low maintenance requirements of these connectors further contribute to their cost-effectiveness.Conclusion:The introduction of Rubber Pipe Connectors' innovative sealing systems for pipe-to-manhole and pipe-to-pipe connections marks a significant breakthrough in the field of wastewater management. These cutting-edge solutions offer enhanced performance, durability, easy installation, and cost-effectiveness. As urban areas continue to expand, the demand for reliable, leak-free, and sustainable connector sealing systems will only grow. Rubber Pipe Connectors' state-of-the-art products bring us one step closer to achieving efficient, robust, and environmentally friendly infrastructures.

Effective Rubber Control Joints for Construction Projects

Today, we are thrilled to introduce a groundbreaking product to the construction and engineering industry - the Rubber Control Joint. This innovative solution is set to revolutionize the way construction professionals approach joint sealing and protection in building structures.The Rubber Control Joint is a high-performance, cost-effective solution designed to provide durable, long-lasting protection for concrete joints in various construction projects. With its advanced technology and superior materials, this product offers unparalleled performance and reliability, making it an essential addition to any construction toolkit.Manufactured by our company, the Rubber Control Joint is the result of years of research and development, aiming to address the growing demand for effective joint sealing solutions in the industry. Our team of expert engineers and technicians have worked tirelessly to create a product that not only meets but exceeds the expectations of our customers.One of the key features of the Rubber Control Joint is its exceptional durability. Made from high-quality rubber materials, this product is designed to withstand the harshest environmental conditions, including extreme temperatures, UV exposure, and heavy foot or vehicle traffic. This ensures that the joints are effectively protected and sealed for an extended period, reducing the need for frequent maintenance and replacements.In addition to its durability, the Rubber Control Joint also offers excellent flexibility, allowing it to accommodate movement and shifting in the concrete structure. This flexibility is crucial in preventing cracks and damage to the concrete, ensuring the structural integrity and longevity of the building.Furthermore, the easy installation process of the Rubber Control Joint makes it a practical and efficient solution for construction professionals. With its simple and straightforward application, this product significantly reduces the time and labor required for joint sealing, resulting in cost savings and improved project timelines.The Rubber Control Joint is suitable for a wide range of construction applications, including commercial buildings, industrial facilities, parking structures, and residential developments. Its versatility and adaptability make it an ideal choice for any construction project where reliable joint protection is essential.As a company committed to excellence, we take great pride in offering the Rubber Control Joint as part of our comprehensive range of construction solutions. With a focus on quality, performance, and innovation, we strive to deliver products that meet the evolving needs of the industry and exceed the expectations of our customers.In conclusion, the introduction of the Rubber Control Joint marks a significant milestone for our company and the construction industry as a whole. With its exceptional durability, flexibility, and easy installation, this product is set to redefine the standards for joint protection and sealing in building structures. We are confident that the Rubber Control Joint will become an indispensable asset for construction professionals, providing them with a reliable and cost-effective solution for their projects.For more information about the Rubber Control Joint and our other construction solutions, please contact us at [company contact information]. We look forward to the opportunity to discuss how our products can elevate the quality and performance of your construction projects.

Discover the Benefits of Expansion Rubber Joints for Improved Flexibility

Expansion Rubber Joint – The Revolutionary Solution for Piping System ProblemsIn today's world, water is a precious commodity that we cannot afford to waste. Consequently, we need to ensure the optimal functioning of our plumbing systems and infrastructure at all times. However, various issues affecting pipe networks, such as corrosion, leaks, and vibrations, pose a significant risk to the system’s efficient operation. If not addressed adequately and promptly, these issues can escalate, leading to costly repairs and system downtime.To tackle these problems, innovative solutions are needed to ensure that piping systems operate optimally while minimizing the risk of maintenance and replacement requirements. One such solution is the Expansion Rubber Joint, an innovative product that has emerged as a revolutionary solution for piping system problems.Expansion Rubber Joint is a flexible joint, also known as a rubber expansion joint, designed to provide the necessary flexibility to piping systems. The product is ideal for water or liquid transportation systems that are susceptible to internal or external vibrations or sudden pressure changes. The joint serves to absorb these vibrations and movements, thus mitigating the risk of damage and leaks, while also providing various other benefits, which we will discuss below.Manufactured by some of the most reputable companies in the industry, Expansion Rubber Joint is made from high-quality materials, including EPDM, neoprene, and natural rubber. These materials ensure resistance to UV, ozone, abrasion, and chemical agents, ensuring durability and longevity.The Expansion Rubber Joint - A Multifaceted SolutionExpansion Rubber Joint offers various benefits that make it an excellent investment for both residential and commercial plumbing systems. Below are some of the product's multifaceted benefits.Flexibility:The flexibility feature of the Expansion Rubber Joint is vital in reducing pipe system failures, minimizing the effect of thermal expansion, and decreasing the stress build-up that causes fractures. The joint allows for movement and expansion, depending on the temperature and pressure changes in the system, ultimately reducing the risk of pipe damage, leaks, and rupture.Vibration Control:Piping systems are susceptible to vibration issues that arise from various external and internal forces. These vibrations can cause significant damage to system components over time. Expansion Rubber Joint is designed to absorb these vibrations, thus reducing the risk of damage or failure and prolonging the system's lifespan.Noise Reduction:Pipework can produce excessive noise that results from the friction caused when fluids pass through the pipes. The noise can be irritating and significantly affect the comfort of building occupants. Expansion Rubber Joint has a noise reduction feature that can help reduce excessive noise levels and improve the comfort of building occupants.Easy Installation:Expansion Rubber Joint is easy to install, making it a preferred solution for most plumbing professionals and DIY enthusiasts. The product comes with installation manuals that show the correct installation procedures and recommended installation equipment.Cost-Effective Solution:The Expansion Rubber Joint is not only cost-effective compared to other flexible joint products but also cost-effective in the long run. With its durability and longevity, it minimizes the need for frequent maintenance and repair, thus saving you money in the long run.ConclusionIn conclusion, when it comes to piping system problems, investing in an Expansion Rubber Joint is an excellent option. Its flexibility, vibration control, noise reduction, ease of installation, and cost-effectiveness make it the ultimate solution for a piping system's effective operation. While there are various flexible joint products in the market, the Expansion Rubber Joint, manufactured by some of the most reputable companies, ensures durability and longevity, making it a worthy investment.So, have you experienced issues with your piping system? If yes, it is time to consider investing in Expansion Rubber Joint.