Types of Expansion Joints for Various Industries

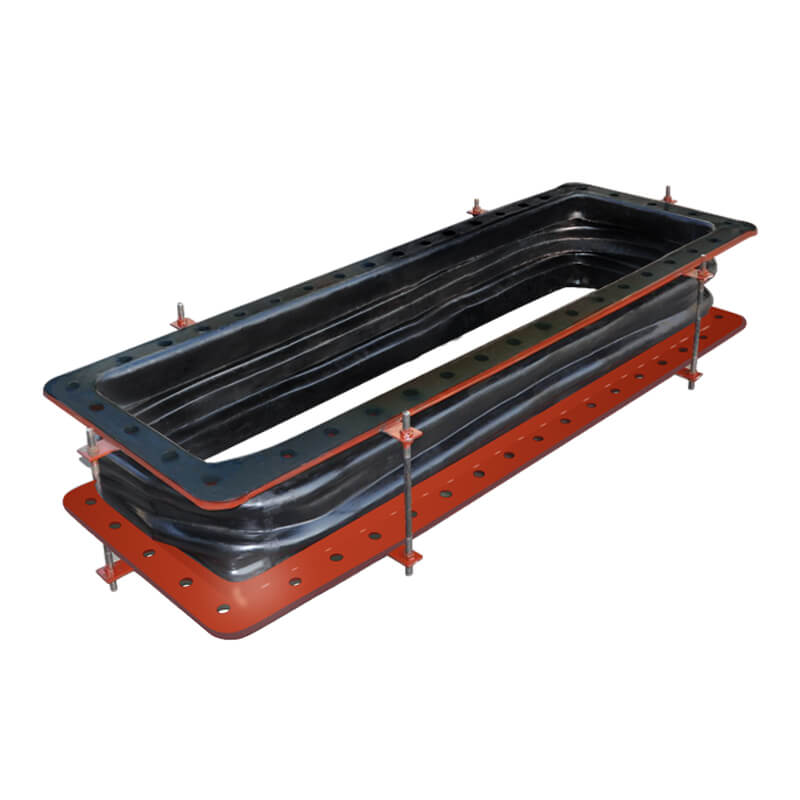

An expansion joint is a vital component in any state-of-the-art piping system. It is necessary to prevent any damage, cracks, or leaks in pipes caused by expansion and contraction due to thermal changes, external pressure, or any other mechanical stress. Expansion joints serve as a flexible connector between the two adjacent pipe sections and allow for movement in a controlled manner. There are various types of expansion joints available in the market to suit a specific application. However, in this article, we will discuss one particular type of expansion joint – filled arch expansion joints.What are filled arch expansion joints?Filled arch expansion joints are a type of expansion joint commonly used in piping systems that encounter high-pressure, high-temperature, or aggressive media. These joints are designed to handle axial, lateral, and angular movements, preventing any damage or degradation of the pipe structure. Filled arch expansion joints comprise two primary components – the metal arch and the filler material.The metal arch is designed in such a way that it can absorb all types of movement experienced in the piping system. It is made up of multiple layers of thin gauge metal sheets welded to form a bellows shape. The shape of the metal arch allows it to compress or expand during thermal changes, lateral or angular movement, while maintaining the pressure integrity of the system.The filler material plays a significant role in the expansion joint’s functioning as it is responsible for providing resistance to the pressure, temperature, and chemical attack of the medium flowing through the piping system. The filler material is commonly made of elastomers or high-temperature resistant materials like Teflon, graphite, or ceramic fibers.When the joint is filled with elastomers, it provides a mechanical seal to the piping system, preventing any leakage or seepage of the medium. Moreover, when the joint is filled with high-temperature resistant materials, it can withstand temperatures up to 1000°F and can handle aggressive media, thus ensuring the safety of the piping system.Advantages of filled arch expansion jointsFilled arch expansion joints offer various benefits when compared to other types of expansion joints. Some of the advantages are as follows:1. Flexibility: Filled arch expansion joints can handle movement in all three planes, axial, lateral, and angular, providing excellent flexibility to the piping system. This prevents the system from experiencing any stress or fatigue, leading to the degradation of the pipeline’s integrity.2. Pressure integrity: Filled arch expansion joints provide excellent pressure integrity to the piping system. The metal arch is designed to absorb any movement of the pipe due to thermal changes or other mechanical stress, maintaining the integrity of the system.3. Leak prevention: Filled arch expansion joints filled with elastomers provide an excellent seal to the piping system, preventing any leakage or seepage of the medium. This ensures the safety of the system and prevents any hazardous incidents.4. High-temperature resistance: Filled arch expansion joints filled with high-temperature resistant materials like Teflon, graphite, or ceramic fibers can withstand high temperatures up to 1000°F. This makes them suitable for applications that require high-temperature processes.ConclusionFilled arch expansion joints are a crucial component in any piping system that requires flexibility, pressure integrity, and leak prevention. They offer various advantages that make them a popular choice among engineers and designers, including resistance to high temperatures, pressure, and chemical attacks. If you are looking for an expansion joint that can handle movement in all three planes while maintaining the integrity of the system, then filled arch expansion joints are an ideal solution.

Read More

Different Types of Expansion Joints for High-Temperature and High-Pressure Applications.

Seiris: Leaders in Providing Customized Rubber Expansion JointsExpansion joints are an important component of several industries and are used to absorb the dimensional changes in piping systems caused by temperature fluctuations and other physical forces. The right quality and design of expansion joints help prevent the premature failure of the piping system and improve its overall efficiency. Seiris is a leading name in the market of expansion joints and has been providing innovative and effective solutions to its clients for over 30 years. Seiris specializes in the customization of various types of expansion joints, including rubber expansion joints, fabric expansion joints, and metal bellows expansion joints. They cater to the specific needs and requirements of their clients to ensure that the expansion joints are designed to fit their systems. Their expertise lies in providing custom-made expansion joints that work seamlessly in highly specific environments and critical applications.Rubber Expansion JointsSeiris's rubber expansion joints are designed to meet the needs of their clients while providing superior performance and durability. They are made from high-quality elastomers to withstand various environmental conditions and resist various chemicals, oil, and other corrosive materials.Rubber expansion joints are suited for a wide range of industrial applications such as the pharmaceutical, power generation, petrochemical, and food and beverage sectors. These systems help absorb the movement in the piping system arising from temperature changes, vibrations, and other physical forces. Seiris's expansion joints are designed to handle temperatures up to 200°C and pressures of up to 20 bars. Fabric Expansion JointsSeiris's fabric expansion joints are designed to include reinforced fabrics such as glass or carbon fiber to withstand high pressures, temperatures, and corrosive environments. They provide exceptional flexibility, which allows for a wide range of movement in the piping system while avoiding disruptive forces. The fabric expansion joints are design-focused and value-engineered and are ideal for industrial applications in petrochemical, power plants, and other settings.Bellows Metal Expansion JointsMetal bellows expansion joints absorb thermal expansion and vibration by providing flexibility, reducing the forces transmitted to adjacent piping. Consisting of nested corrugations, metal bellows expansion joints are well-suited to handle high pressures and temperatures up to 500°C. Seiris provides these joints in a range of materials such as stainless steel and nickel alloys for chemical and corrosive applications. Tailored Solutions for Expansion JointsSeiris prides itself on being able to provide tailored expansion joint solutions for various industrial applications such as power plants, oil and gas facilities, and other critical settings. They offer a complete range of engineering services - from initial design and calculations through to fabrication, delivery, and commissioning support. With their expertise and technical knowledge, they take each customer's unique requirements into consideration and design custom-made expansion joints accordingly.Seiris offers unparalleled quality and long-term durability along with a commitment to timely delivery and excellent customer support. They use the latest technology and the most innovative design practices to achieve the required durability and flexibility for their clients. ConclusionChoosing the right expansion joint is crucial to ensure the long-term stability and performance of piping systems. Seiris's extensive experience and expertise in the expansion joint industry ensure that their clients receive effective solutions tailored to their specific requirements, all while delivering exceptional quality engineering services. With a commitment to innovation, customer satisfaction and support, Seiris continues to stand out in the industry as leaders in providing customized expansion joints. For further information, please visit: [Need to remove anchor text]

Read More

Discover the Benefits of Metal Bellows Packless Expansion Joints

Metal Bellows Packless Expansion Joints – The Future of Piping SystemsThe use of pipes in various industries like manufacturing, aerospace, and oil and gas requires certain devices that can help in accommodating the expansion and contraction of the pipes due to temperature changes. One such device that is gaining popularity in the market is the Metal Bellows Packless Expansion Joint.Metal Bellows Packless Expansion Joints are flexible pipe connectors that help in reducing the stresses caused by the thermal expansion and contraction of pipes. They are designed to accommodate axial, lateral, and angular movement of pipes without changing the direction of the flow, making them a perfect solution for piping systems that require a high degree of flexibility and durability.The Metal Bellows Packless Expansion Joints are made of high-quality metal alloy bellows that can withstand high temperatures and pressure fluctuations. These joints are specially designed to provide a leak-proof seal, eliminating the risk of fluid leakage and ensuring the safety of the overall piping system.One of the key advantages of Metal Bellows Packless Expansion Joints is their long service life. These expansion joints are highly durable and resistant to wear and tear, ensuring that they provide a reliable solution for the long term.Another benefit of Metal Bellows Packless Expansion Joints is their ease of installation. They come in various sizes and configurations to fit different types of piping systems. This makes them easy to install and maintain, reducing the overall downtime of the system.At {company name}, we are committed to providing our customers with the best quality Metal Bellows Packless Expansion Joints. Our expansion joints are manufactured using state-of-the-art technology, ensuring that they meet the highest industry standards.Our team of experts works closely with our clients to understand their specific requirements and provide customized solutions. We offer a wide range of Metal Bellows Packless Expansion Joints in different sizes and configurations to meet the unique needs of our clients.In addition to our high-quality products, we also provide exceptional customer service to our clients. Our team of experts is available round the clock to provide support and assist our clients in any way possible.Overall, Metal Bellows Packless Expansion Joints are a reliable solution for piping systems that require flexibility and durability. With their long service life and ease of installation, these expansion joints are the future of the piping industry. If you are looking for high-quality Metal Bellows Packless Expansion Joints, {company name} is your one-stop solution!

Read More

Effective Sealing Systems for Pipe-to-Manhole and Pipe-to-Pipe Connections

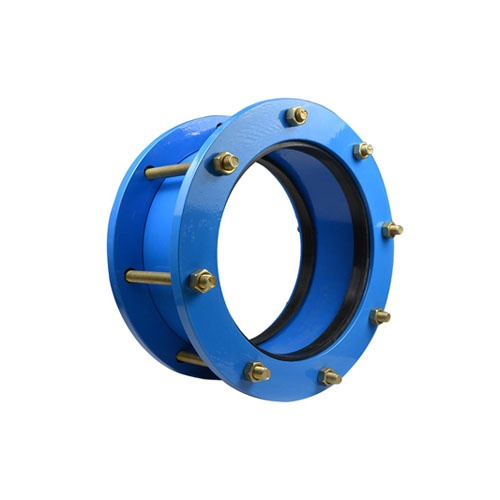

Title: Innovative Connector Sealing Systems Revolutionize Pipe-to-Manhole and Pipe-to-Pipe ConnectionsIntroduction:The growth of urban infrastructure and the need for efficient wastewater management have led to an increased demand for reliable and durable pipe connectors. Recognizing this, Rubber Pipe Connectors has introduced pioneer connector sealing systems that aim to revolutionize pipe-to-manhole and pipe-to-pipe connections. These innovative solutions ensure seamless integration, improve performance, and enhance the overall efficiency of wastewater management systems.Connector Sealing Systems:1. Pipe-to-Manhole Connector Sealing Systems:Rubber Pipe Connectors has developed a cutting-edge range of connector sealing systems designed specifically for pipe-to-manhole connections. These connectors provide an air and watertight seal, preventing leakage and minimizing the risk of contamination. By eliminating the possibility of seepage, these sealing systems contribute to a healthier environment and a safer infrastructure.Utilizing the latest materials and manufacturing techniques, these connectors ensure easy installation, enhanced durability, and reduced maintenance requirements. The precisely engineered design of the connectors ensures a secure and long-lasting connection, even under demanding conditions.2. Pipe-to-Pipe Connector Sealing Systems:In addition to pipe-to-manhole connections, Rubber Pipe Connectors offers an exceptional range of connector sealing systems for pipe-to-pipe connections. These connectors facilitate the efficient flow of wastewater between different pipe sections and ensure a reliable and leak-free transition.Rubber Pipe Connectors' pipe-to-pipe sealing systems are tailored to accommodate various pipe sizes and materials commonly used in wastewater management. Their flexibility allows for easy installation and adaptability, minimizing the need for costly alterations or replacements. These connectors simplify the maintenance process and contribute to the longevity of the entire piping system.Advantages of Rubber Pipe Connectors' Sealing Systems:1. Enhanced Performance: Rubber Pipe Connectors' sealing systems ensure a secure and reliable connection that mitigates the risk of leaks, seepage, and potential contamination. By maintaining the integrity of the system, these connectors contribute to a more efficient wastewater management process.2. Durability: The cutting-edge materials and manufacturing techniques employed by Rubber Pipe Connectors guarantee the longevity and durability of their sealing systems. Withstanding the test of time and demanding operational conditions, these connectors reduce the need for frequent replacements or maintenance.3. Easy Installation and Adaptability: Rubber Pipe Connectors' sealing systems are designed with easy installation in mind, significantly reducing downtime during system installation or repairs. Their adaptability to various pipe sizes and materials simplifies the connection process, streamlining the overall operation.4. Cost-Effectiveness: By providing reliable and leak-free connections, Rubber Pipe Connectors' sealing systems minimize the occurrence of costly repairs and potential damage caused by leakage. The durability and low maintenance requirements of these connectors further contribute to their cost-effectiveness.Conclusion:The introduction of Rubber Pipe Connectors' innovative sealing systems for pipe-to-manhole and pipe-to-pipe connections marks a significant breakthrough in the field of wastewater management. These cutting-edge solutions offer enhanced performance, durability, easy installation, and cost-effectiveness. As urban areas continue to expand, the demand for reliable, leak-free, and sustainable connector sealing systems will only grow. Rubber Pipe Connectors' state-of-the-art products bring us one step closer to achieving efficient, robust, and environmentally friendly infrastructures.

Read More

Flexible Joints Used for Industrial Applications: A Comprehensive Overview

Title: Advanced Flexible Joint Revolutionizes Industrial Piping Systems Introduction:In an era where efficiency and reliability are paramount, industrial companies are constantly seeking innovative solutions to enhance their operations. {Company name}, a leading provider of cutting-edge engineering solutions, has recently unveiled its ground-breaking Double Bellow Flexible Joint. This advanced technology is expected to revolutionize industrial piping systems, offering unprecedented flexibility, durability, and safety to various sectors.Flexible Joint Redefined:The Double Bellow Flexible Joint, designed and manufactured by {Company name}, marks a significant leap forward in flexible joint technology. This game-changing solution focuses on maximizing performance, reducing maintenance costs, and ensuring safe and efficient operations.Unmatched Flexibility:Thanks to an ingenious design, the Double Bellow Flexible Joint permits a superior range of movements, allowing for greater flexibility in industrial piping systems. Its double-layered bellows construction enables enhanced axial, lateral, and angular movements, accommodating any vibrations or shifts in piping systems. This remarkable flexibility significantly minimizes potential stress on pipelines, thereby increasing their lifespan and reducing the risk of leaks or structural failures.Unparalleled Durability and Reliability:Engineered using only the highest quality materials, the Double Bellow Flexible Joint offers unparalleled durability and long-term reliability. The bellows are constructed from corrosion-resistant alloys, ensuring resistance to harsh chemicals, extreme temperatures, and other demanding environments. This robust construction guarantees exceptional performance in even the most challenging industrial applications.Enhanced Safety Measures:One of the primary focuses behind the creation of the Double Bellow Flexible Joint was the desire to enhance safety standards in industrial piping systems. With built-in safety features, such as an internal liner and break protection system, this innovative technology significantly reduces the risk of leakages and potential hazards. By mitigating these potential dangers, companies can ensure the safety of their personnel, protect their assets, and avoid costly downtime.Versatility in Applications:The Double Bellow Flexible Joint by {Company name} meets the demands of various industrial sectors, including oil and gas, chemical processing, power generation, and many more. Its versatile design enables seamless integration into existing piping infrastructures, allowing for an effortless upgrade without significant modifications. This adaptability makes it an ideal solution for maintenance and retrofit projects.Positive Impact on Operational Efficiency:By incorporating the Double Bellow Flexible Joint into their piping systems, companies can achieve remarkable improvements in operational efficiency. Its ability to absorb vibrations and movements reduces stress on pipelines and adjacent equipment, minimizing the need for frequent maintenance and costly repairs. This enhanced reliability translates into higher productivity, extended equipment lifetimes, and reduced overall operational costs.Environmentally Friendly Technology:With a growing focus on sustainability and environmental consciousness, the Double Bellow Flexible Joint takes center stage as a more eco-friendly alternative. By preventing leakages and reducing the risk of pipeline failures, this advanced solution helps to minimize the release of hazardous substances into the environment. Furthermore, its durability ensures less frequent replacements, resulting in a lower carbon footprint overall.Conclusion:With the introduction of the Double Bellow Flexible Joint, {Company name} continues to lead the way in pioneering engineering solutions. This innovative technology pushes the boundaries of flexible joint performance, providing unmatched flexibility, durability, and safety in industrial piping systems. As companies across various sectors embrace this revolutionary solution, they can look forward to increased operational efficiency, reduced maintenance costs, and the assurance of enhanced safety in their operations.

Read More

Discover the Benefits of EPDM Tubing and Its Various Applications

EPDM Tube Type EE: A Breakthrough in Rubber Tubing Technology{Company name} is pleased to announce the launch of their latest innovation in rubber tubing technology - the EPDM Tube Type EE. This breakthrough product is set to revolutionize the industry with its superior performance and unique features, catering to a wide range of applications across various sectors.EPDM, or Ethylene Propylene Diene Monomer, is a type of synthetic rubber known for its excellent resistance to heat, ozone, and weathering. This makes it an ideal material for creating durable and reliable tubing solutions, especially in demanding environments. The EPDM Tube Type EE has been specifically engineered to provide enhanced performance compared to traditional rubber tubing, offering increased flexibility, resilience, and longevity.One of the key advantages of the EPDM Tube Type EE is its exceptional resistance to temperature extremes. It can withstand both high and low temperatures, making it suitable for use in a wide range of industrial and commercial applications, including automotive, construction, HVAC, and more. This versatility allows for seamless integration into various systems and processes, providing a reliable and long-lasting solution for a diverse array of needs.In addition to its temperature resistance, the EPDM Tube Type EE also boasts superior resistance to ozone and UV exposure, ensuring that it can maintain its integrity and functionality even in the harshest environmental conditions. This makes it an ideal choice for outdoor applications where exposure to the elements is a concern, providing peace of mind and reliability for users across different industries.Furthermore, the EPDM Tube Type EE offers excellent chemical resistance, safeguarding against degradation and corrosion caused by exposure to various chemicals and solvents. This feature makes it a preferred option for applications where contact with potentially corrosive substances is inevitable, ensuring the longevity and safety of the tubing in such environments.{Company name} has a long-standing reputation for delivering high-quality rubber products, and the introduction of the EPDM Tube Type EE further solidifies their commitment to innovation and excellence. With a focus on research and development, and a dedication to meeting the evolving needs of their customers, the company continues to lead the way in advancing rubber technology, providing cutting-edge solutions that set new standards in the industry.Furthermore, the EPDM Tube Type EE is manufactured to meet stringent quality standards, ensuring consistency, reliability, and performance across every unit produced. This commitment to quality is a hallmark of {Company name}, reflecting their unwavering dedication to delivering products that exceed expectations and provide unmatched value to their customers.In conclusion, the introduction of the EPDM Tube Type EE marks a significant milestone in the advancement of rubber tubing technology. With its exceptional resistance to heat, ozone, and weathering, as well as its superior flexibility, resilience, and chemical resistance, this innovative product is set to redefine the standards of performance and reliability in the industry. {Company name} remains at the forefront of innovation, and the EPDM Tube Type EE is a testament to their ongoing commitment to excellence and customer satisfaction.

Read More

EPDM Roofing: A Sustainable and Affordable Commercial Roofing Option"

EPDM (ethylene propylene diene monomer) roofing has become one of the most popular and sustainable options for commercial roofing. It is a single-ply membrane that has been widely accepted and respected in the industry for its long-term roofing solutions. With a history of several decades, EPDM roofing is lightweight, relatively inexpensive, and easy to install. Its eco-friendly benefits and durability have made it a top choice for commercial properties. Experienced roofing contractors like Landmark Roofing can provide expert installation services for EPDM roofing.

Enduring durability and enhanced performance are the hallmarks of EPDM roofing. With its outstanding resistance to UV rays, inclement weather, and extreme temperatures, it has been widely acknowledged as the go-to roofing solution for commercial and industrial buildings.EPDM, or Ethylene Propylene Diene Monomer, is made up of a polymer that is synthesized from a blend of several compounds, including ethylene, propylene, and a third diene monomer. These compounds are then processed using a variety of methods, including extrusion, calendering, and molding, to create a sheet that is tough, flexible, and fatigue-resistant.As a single-ply membrane, EPDM roofing is incredibly lightweight, making it easy to install and maintain. Its membrane is typically held in place using a variety of fasteners, such as adhesives, tacks, or plates, depending on the application and the needs of the building. This results in a low-maintenance, weather-resistant roofing system that can last for decades.One of the most significant advantages of EPDM roofing is its cost-effectiveness. Compared to other commercial roofing materials, EPDM roofing is relatively inexpensive, offering a lower initial cost and lower maintenance costs in the long run. This makes it an ideal solution for small and medium-sized businesses that are looking for a reliable roofing material that won't break the bank.EPDM roofing is also an eco-friendly option that offers several advantages over other roofing materials. Due to its composition, it is entirely recyclable, making it a sustainable choice for environmentally-conscious businesses. Moreover, EPDM roofs help reduce energy bills by reflecting sunlight and cooling the building, reducing the amount of heat absorbed and the workload of HVAC systems.Another benefit of EPDM roofing is its versatility. It can be customized for use with different types of roofing systems, including flat, low-sloped, and domed roofs. The geodesic dome shape, for instance, is becoming increasingly popular in commercial roofing applications, due to its unique design and energy-efficient properties.EPDM roofing also has an excellent reputation for resistance to expansion and contraction, which is essential in climates that experience significant temperature fluctuations. This high level of flexibility and stretchability ensures that the roofing material remains intact and watertight, regardless of the weather conditions.At Landmark Roofing, we're proud to be experts in the installation, maintenance, and repair of EPDM roofing systems. Our team of experienced and certified professionals can help you choose the right roofing solution for your building and provide ongoing support to ensure that your roof lasts for years to come.In conclusion, EPDM roofing is a versatile, cost-effective, and eco-friendly solution that offers superior performance in a range of commercial roofing applications. Its outstanding resistance to UV rays, inclement weather, and extreme temperatures has made it an industry standard, and its ease of installation and maintenance make it an ideal choice for businesses of all sizes. When it comes to EPDM roofing, choose Landmark Roofing for expert installation and ongoing support.

Read More

High-Quality Rubber Joint Pipes for Efficient Pipe Connections

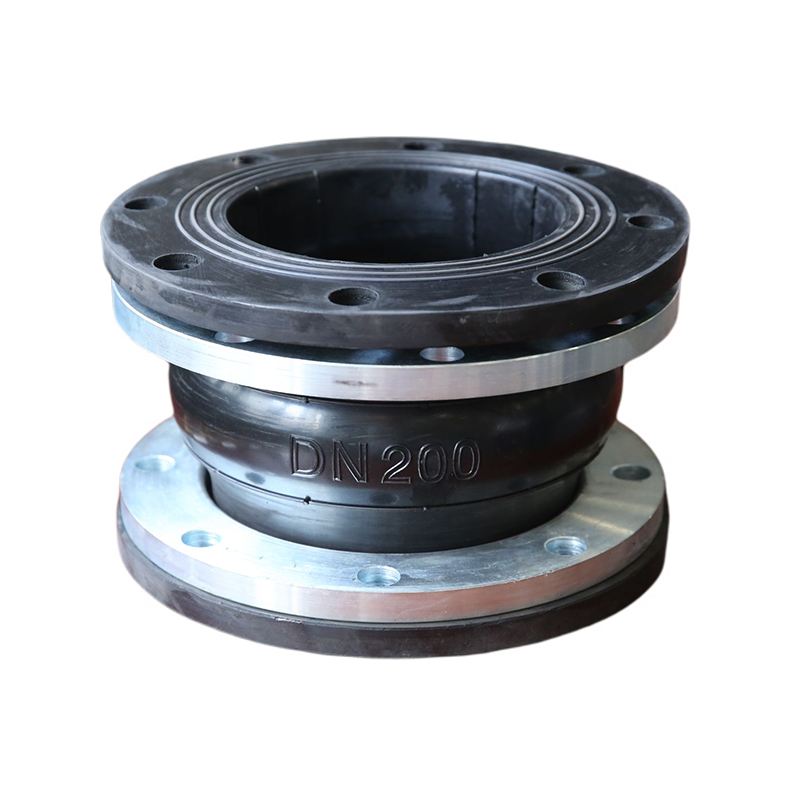

Rubber Joint Pipe: Providing Excellent Performance and Quality Solutions to Different IndustriesRubber Joint Pipe is a well-known brand in the industry of flexible pipe connections. The company has been providing technical solutions and expertise for more than two decades, delivering rubber expansion joints, metallic expansion joints, and accessories for piping systems in different industries worldwide. The headquarters of Rubber Joint Pipe is located in Hong Kong with several manufacturing units around the world. The team of technical experts, engineers, and skilled workers ensure high-performance and reliable solutions to different projects.The company's products have been designed to accommodate different applications, such as water treatment, sewage systems, marine, chemical, power plants, construction, and HVAC. The rubber expansion joints are made of different materials, including NR, neoprene, EPDM, and Viton, each with specific features such as weather resistance, high temperature, oil resistance, and chemical resistance.One of the latest innovative products of Rubber Joint Pipe is the double-sphere rubber expansion joint, which is designed to handle a larger range of movements, misalignments, and vibrations. This expansion joint is composed of two spheres connected by a flexible rubber body, allowing for axial compression and extension, lateral and angular movements, and torsional flexibility. The double-sphere rubber expansion joint can also absorb and dampen vibrations, reducing noise and prolonging the lifespan of piping systems.The metallic expansion joints of Rubber Joint Pipe are also made of different materials, including stainless steel, carbon steel, and alloy steel, depending on the application and the specific requirements. The metallic expansion joints can accommodate higher temperatures and pressures, larger movements, and a longer lifespan than rubber expansion joints. The metallic expansion joints are also available in different configurations, such as single, double, and universal, with different types of bellows, such as convolution, annular, and multi-ply.Rubber Joint Pipe's team of technical experts and engineers can provide customized solutions and design services for different projects. The company uses advanced software for finite element analysis, 3D modeling, and stress calculation, ensuring the accuracy and reliability of the products. The company also adheres to international standards such as ISO, ASME, DIN, and ASTM, and collaborates with third-party inspectors for quality assurance and testing.Rubber Joint Pipe also offers a range of accessories such as flanges, tie rods, bolts, nuts, gaskets, and protective covers, ensuring a complete and reliable solution for piping systems. The company has a wide range of clients, including contractors, engineers, consultants, end-users, and distributors from different industries worldwide.Rubber Joint Pipe has built a strong reputation for providing excellent performance and quality solutions for flexible pipe connections. The company's products have been installed in different projects such as the sewage treatment plant in Malaysia, the chemical plant in Saudi Arabia, the power plant in Egypt, and the HVAC system in the USA. The company aims to keep innovating and improving its products and services to meet the ever-growing demand of the market and the customers.Rubber Joint Pipe's commitment to quality, reliability, innovation, and technical expertise has made it a leading player in the industry of flexible pipe connections. The company's products and services have been recognized and trusted by different clients worldwide. With its wide range of products, customized solutions, and excellent customer service, Rubber Joint Pipe is poised to meet and exceed the expectations of its customers in different industries.

Read More

Stainless Steel Braided Flexible Tap Connector for High-Pressure Applications

Flexible Tap Connectors: The Ideal Way to Connect Taps and AppliancesOne of the key components in any plumbing system is the tap connector. Tap connectors are used to join pipework to appliances or taps and come in a variety of materials and designs. One of the most popular types of tap connectors is the flexible tap connector, which offers numerous benefits and advantages over traditional rigid pipework connections.In this blog post, we will take a closer look at flexible tap connectors, their features, and the reasons why they are the ideal way to connect taps and appliances in any plumbing system.What Is a Flexible Tap Connector?A flexible tap connector is a type of flexible hose that is designed to connect taps and other appliances to the water supply. It is made up of a stainless steel over braided EPDM rubber tube that is reinforced with a flexible steel mesh. This design provides excellent flexibility, durability, and strength, making it ideal for use in a variety of plumbing applications.Flexible tap connectors are available in a range of sizes and lengths to suit different plumbing systems. They typically come with one compression end and a swivel nut with a washer on the other end, which allows for easy and quick installation.Features of Flexible Tap ConnectorsStainless Steel Over Braided EPDM Rubber Tube: The main feature of a flexible tap connector is the stainless steel over braided EPDM rubber tube. This material is highly durable and resistant to corrosion, making it ideal for use in wet and humid environments.Nickel Plated Brass Fittings: The fittings that come with flexible tap connectors are made from nickel plated brass. This gives them excellent strength and durability, as well as protection against corrosion.15 Bar Max Working Pressure: Flexible tap connectors are designed to withstand high pressure and are rated at a maximum working pressure of 15 bar. This makes them suitable for use in a variety of plumbing systems.One Compression End & Swivel Nut: Flexible tap connectors come with a compression end and a swivel nut at the other end. This allows for easy installation and makes it easy to connect taps and appliances to the plumbing system.70C Max Temp: Flexible tap connectors are designed to operate in temperatures of up to 70C, making them suitable for use in hot water systems.Advantages of Flexible Tap ConnectorsEasy to Install: Flexible tap connectors are incredibly easy to install. They are designed to be flexible, which means they can be easily bent and manoeuvred into place, making installation quick and straightforward.Reduced Leak Risk: Traditional rigid pipework connections can often be prone to leaks. However, flexible tap connectors are designed to reduce the risk of leaks, thanks to their strong and durable construction.Flexible Design: The flexible design of flexible tap connectors means they can be easily and quickly adjusted to fit the requirements of different plumbing systems. This makes them a versatile solution that can be used in a wide variety of applications.Reduced Noise: The flexible design of flexible tap connectors can also help to reduce noise in the plumbing system. This makes them ideal for use in residential and commercial buildings, where noise can be an issue.Improved Aesthetics: Flexible tap connectors are also available in a range of colours and styles, which means they can be matched to the design and colour scheme of different plumbing systems. This can help to improve the overall aesthetics of the system.ConclusionFlexible tap connectors are an essential component in any plumbing system. They provide numerous benefits, including flexibility, durability, and ease of installation. They are also available in a variety of sizes, lengths, and styles, making them suitable for use in a wide range of applications. If you are looking to improve your plumbing system's performance, then flexible tap connectors are the ideal solution. So, why not invest in flexible pump connectors today?

Read More

High-Quality Flanges, Pipe Fittings, and More for Industrial Use

Flanges | Batam Teknik Medan: Delivering Premium Quality Products Since 1973Batam Teknik Medan was established in the year 1973. The company has a rich history and has been serving the industry for over four decades. It specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With a sound understanding of the industry and over four decades of experience in the field, the company has earned a reputation as a reliable and trusted supplier of industrial goods.The company offers a comprehensive range of products that caters to all the industrial needs of the customers. It is committed to providing high-quality products and services to the clients to meet their requirements. The team of experts working with the company has a sound knowledge of the products and the technological advancements in the industry. This helps the company to keep up with the changing trends and deliver innovative, top-quality products and services to its customers.One of the key products that the company supplies is flanges. Flanges are essential components used in piping systems. These components are used to connect pipes to each other or to a valve or other equipment. The flanges must be sturdy and reliable to prevent leaks and maintain the flow of fluids or gases through the pipes. At Batam Teknik Medan, the flanges are made of the highest quality components, which ensures their durability and resistance to corrosion. The company offers flanges in different sizes and types to meet the requirements of the customers.Batam Teknik Medan is known for its reliable, timely, and efficient services. The company ensures that its customers receive their orders promptly and accurately. The team at Batam Teknik Medan is committed to delivering quality products and meeting customer needs.The company has achieved remarkable growth over the years, largely due to its commitment to quality, reliability, and customer satisfaction. It has built a strong reputation in the industry and has been recognized for its exceptional services. The company has a diverse clientele, including large multinational corporations, SMEs, and start-up businesses. The company has established long-term relationships with its clients and continues to provide them with premium quality products and services.Batam Teknik Medan has evolved over the years and has kept up with the changing times and trends in the industry. The company is committed to innovation and offers a comprehensive range of products to meet the needs of its diverse clientele. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.In conclusion, Batam Teknik Medan is a reliable and trusted supplier of industrial goods in the region. The company specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With over four decades of experience, the company has built a reputation for providing high-quality products and services to its customers. The company has a team of experts who have a sound understanding of the industry, and it is committed to delivering innovative, top-quality products and services to meet customer needs. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.

Read More