Ultimate Guide to Pump Flexible Joints: What You Need to Know

By:Admin

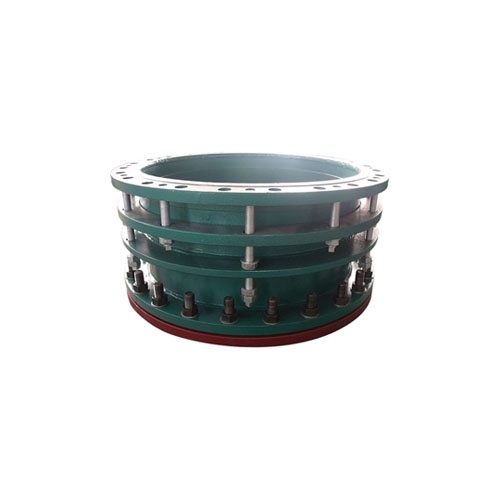

{Company Name} was established in the early 2000s with a mission to provide top-notch pump accessories and components to businesses worldwide. With a strong emphasis on research and development, the company has continuously strived to enhance its product line and develop new technologies that align with the evolving needs of the industry. This commitment has enabled {Company Name} to gain a strong foothold in the market and establish itself as a trusted and reliable supplier of pump flexible joints.

The pump flexible joints manufactured by {Company Name} are engineered to withstand the rigors of industrial environments. They are made from high-quality materials, ensuring durability and longevity. Moreover, the company’s dedication to quality control and testing procedures guarantees that each flexible joint meets stringent industry standards and specifications.

One of the key features of {Company Name}’s pump flexible joints is their flexibility and adaptability. They are designed to accommodate a wide range of movements and vibrations, making them suitable for various types of pumps and piping systems. This versatility has made {Company Name} a preferred choice for businesses looking for reliable and cost-effective solutions for their pumping needs.

In addition to its product quality, {Company Name} is also known for its exceptional customer service. The company’s team of experts is committed to providing comprehensive support to clients, from selecting the right flexible joint for their specific requirements to offering technical assistance and guidance throughout the installation and maintenance processes.

As the demand for pump flexible joints continues to grow, {Company Name} has been proactive in expanding its production capacity and optimizing its manufacturing processes. The company has invested in advanced machinery and technology to enhance efficiency and productivity, allowing it to fulfill large orders and meet tight deadlines without compromising on quality.

Furthermore, {Company Name} has been dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, from sourcing raw materials to waste management, to minimize its ecological footprint. This commitment to sustainability has not only earned {Company Name} a positive reputation in the industry but has also contributed to its long-term success and growth.

Looking ahead, {Company Name} is poised to continue its trajectory of success in the market for pump flexible joints. The company remains focused on innovation and diversification, exploring new opportunities and partnerships to further expand its product offerings and reach new markets. With a steadfast commitment to excellence and customer satisfaction, {Company Name} is set to remain a leader in the industry and a go-to choice for businesses seeking reliable pump accessories and components.

In conclusion, {Company Name} has etched its name as a pioneer in the manufacturing of pump flexible joints, setting industry standards for quality, reliability, and innovation. With a strong focus on customer satisfaction, sustainability, and continuous improvement, the company is well-positioned to meet the evolving needs of the market and maintain its position as a key player in the industry.

Company News & Blog

Find the Latest Prices of Expansion Joints and Bellows in India

Expansion Joints - Supporting Seamless Movement in Piping SystemsOften overlooked, expansion joints and bellows play an integral role in ensuring the smooth functioning of piping systems. The installation of these components reduces the stress on pipes by absorbing mechanical and thermal movements resulting from changes in pressure, temperature, and vibrations. They prevent cracking, failures, and leaks that may occur due to thermal expansion, contraction, or misalignment.Expansion Bellows Joint, a leading manufacturer and supplier of expansion joints and bellows in India, offers a comprehensive range of products to meet the needs of diverse industries and applications. They provide custom-designed solutions for critical and challenging installations while adhering to international standards and quality assurance practices.Expansion Joints - Types and ApplicationsExpansion joints come in various types, shapes, and materials to cater to specific requirements and environmental conditions. Some commonly used expansion joint types include:1. Metal Expansion Joints - These are made of stainless steel, carbon steel, or other alloys and are ideal for high-temperature and corrosive applications.2. Rubber Expansion Joints - These consist of elastomeric rubber or neoprene material and are used in applications where the movement is minimal and can absorb small vibrations.3. Fabric Expansion Joints - These are composed of high-temperature resistant fabrics such as fiberglass or Teflon and are suitable for applications involving high-temperature and low-pressure.4. PTFE Expansion Joints - These are made of Polytetrafluoroethylene (PTFE) material and are used in applications where resistance to chemicals, high temperature, and pressure is required.5. Tied Universal Expansion Joints - These are designed to handle multi-plane movements and are often used in piping systems involving flue gas ducts or petrochemical plants.Expansion Bellows Joint offers all these types of expansion joints and can provide customized solutions based on the specific application.Expansion Joints - Benefits and FeaturesProper installation of expansion joints results in significant benefits for piping systems. Some prominent features of expansion joints include:1. Absorption of movements resulting from thermal expansion, contraction, and misalignment.2. Reduced stress on pipes and fittings, leading to a longer lifespan of the entire system.3. Preventing costly repairs and downtime associated with pipe failures and leaks.4. Ideal for applications involving high temperatures, chemicals, and corrosive environments.Expansion Bellows Joint utilizes the latest technology and materials to manufacture high-quality expansion joints with the following features:1. Compliance with international standards such as EJMA, ASME, and ASTM.2. Multiple plies of stainless steel or other alloys for enhanced strength and durability.3. Competitively priced with quick turnaround times for custom orders.ConclusionTo sum up, expansion joints and bellows are crucial components of piping systems that ensure their efficient functioning and reduce the risk of failures. Expansion Bellows Joint, with its vast experience, quality products, and customized solutions, is the go-to choice for industry players requiring expansion joints. With their commitment to quality, reliability, and customer satisfaction, they continue to lead the expansion joint market in India and are poised for global expansion.

Types of Expansion Joints for Various Industries

An expansion joint is a vital component in any state-of-the-art piping system. It is necessary to prevent any damage, cracks, or leaks in pipes caused by expansion and contraction due to thermal changes, external pressure, or any other mechanical stress. Expansion joints serve as a flexible connector between the two adjacent pipe sections and allow for movement in a controlled manner. There are various types of expansion joints available in the market to suit a specific application. However, in this article, we will discuss one particular type of expansion joint – filled arch expansion joints.What are filled arch expansion joints?Filled arch expansion joints are a type of expansion joint commonly used in piping systems that encounter high-pressure, high-temperature, or aggressive media. These joints are designed to handle axial, lateral, and angular movements, preventing any damage or degradation of the pipe structure. Filled arch expansion joints comprise two primary components – the metal arch and the filler material.The metal arch is designed in such a way that it can absorb all types of movement experienced in the piping system. It is made up of multiple layers of thin gauge metal sheets welded to form a bellows shape. The shape of the metal arch allows it to compress or expand during thermal changes, lateral or angular movement, while maintaining the pressure integrity of the system.The filler material plays a significant role in the expansion joint’s functioning as it is responsible for providing resistance to the pressure, temperature, and chemical attack of the medium flowing through the piping system. The filler material is commonly made of elastomers or high-temperature resistant materials like Teflon, graphite, or ceramic fibers.When the joint is filled with elastomers, it provides a mechanical seal to the piping system, preventing any leakage or seepage of the medium. Moreover, when the joint is filled with high-temperature resistant materials, it can withstand temperatures up to 1000°F and can handle aggressive media, thus ensuring the safety of the piping system.Advantages of filled arch expansion jointsFilled arch expansion joints offer various benefits when compared to other types of expansion joints. Some of the advantages are as follows:1. Flexibility: Filled arch expansion joints can handle movement in all three planes, axial, lateral, and angular, providing excellent flexibility to the piping system. This prevents the system from experiencing any stress or fatigue, leading to the degradation of the pipeline’s integrity.2. Pressure integrity: Filled arch expansion joints provide excellent pressure integrity to the piping system. The metal arch is designed to absorb any movement of the pipe due to thermal changes or other mechanical stress, maintaining the integrity of the system.3. Leak prevention: Filled arch expansion joints filled with elastomers provide an excellent seal to the piping system, preventing any leakage or seepage of the medium. This ensures the safety of the system and prevents any hazardous incidents.4. High-temperature resistance: Filled arch expansion joints filled with high-temperature resistant materials like Teflon, graphite, or ceramic fibers can withstand high temperatures up to 1000°F. This makes them suitable for applications that require high-temperature processes.ConclusionFilled arch expansion joints are a crucial component in any piping system that requires flexibility, pressure integrity, and leak prevention. They offer various advantages that make them a popular choice among engineers and designers, including resistance to high temperatures, pressure, and chemical attacks. If you are looking for an expansion joint that can handle movement in all three planes while maintaining the integrity of the system, then filled arch expansion joints are an ideal solution.

Durable Neoprene Rubber Bellows for Industrial Use

Neoprene Rubber Bellows have been making waves in the industry with their high-quality, durable and versatile products. Known for their expertise in manufacturing rubber bellows, their neoprene rubber bellows are one of the most sought-after products in the market. With a wide range of applications, these bellows have become a staple in various industries such as automotive, aerospace, marine, and construction.The company, {Company Name}, has been a leading manufacturer of rubber products for over 20 years. Their dedication to quality and innovation has made them a trusted name in the industry. Their state-of-the-art facilities and highly-skilled workforce have allowed them to consistently deliver top-notch products that meet the highest standards.Neoprene rubber bellows are known for their exceptional resistance to oil, heat, and weathering, making them ideal for harsh and demanding environments. This makes them a popular choice for use in machinery, equipment, and vehicles that operate in extreme conditions. The flexibility and durability of neoprene rubber bellows also make them an excellent choice for sealing and protecting moving parts, ensuring smooth and reliable operation.One of the key benefits of neoprene rubber bellows is their ability to provide a tight seal, preventing the ingress of dirt, dust, and moisture. This not only helps to extend the lifespan of the equipment but also reduces the need for maintenance and repairs. Additionally, their resistance to chemicals and oils makes them suitable for use in a wide range of industrial applications, further cementing their versatility and reliability.The neoprene rubber bellows from {Company Name} are available in various sizes, shapes, and configurations to suit different requirements. Their team of experienced engineers and technicians work closely with clients to understand their specific needs and provide tailored solutions that meet their exact specifications. Whether it's a standard design or a custom-made product, {Company Name} has the expertise and capability to deliver a solution that fits the bill.In addition to their high-quality products, {Company Name} is also committed to sustainability and environmental responsibility. They adhere to strict environmental standards and regulations in their manufacturing processes, ensuring minimal impact on the environment. Their eco-friendly approach has earned them recognition and praise from customers and industry peers alike.Furthermore, the company's dedication to customer satisfaction is evident in their after-sales service and support. Their team of knowledgeable professionals is always on hand to offer assistance and technical advice, ensuring that clients get the most out of their products. This commitment to excellence has earned {Company Name} a loyal and satisfied customer base, further solidifying their reputation as a leader in the industry.Looking ahead, {Company Name} is poised to continue their success and innovation in the manufacturing of neoprene rubber bellows. With a focus on research and development, they are constantly exploring new technologies and materials to further enhance their products. This unwavering dedication to improvement and progress makes them a formidable force in the industry.In conclusion, neoprene rubber bellows from {Company Name} have undoubtedly set a new standard in the industry. With their exceptional quality, versatility, and commitment to excellence, they have earned the trust and loyalty of customers across various sectors. As they continue to innovate and expand their capabilities, {Company Name} is certain to remain at the forefront of rubber bellows manufacturing for years to come.

Comprehensive Guide to Expansion Bellow Specifications for Industrial Applications

Expansion Bellow Specification for Improved Performance and Safety in Industrial ApplicationsDate:In today's rapidly evolving industrial sector, the demand for high-performance equipment and systems continues to grow. One crucial component that plays a significant role in ensuring the smooth functioning of various industrial processes is expansion bellows. These flexible devices are designed to absorb thermal expansion and contraction, vibrations, and misalignments in pipelines, thereby preventing damage to critical infrastructure and improving overall safety.Company Introduction{Company Name} is a leading manufacturer and supplier of expansion bellows, catering to a wide range of industries such as oil and gas, petrochemical, power generation, water treatment, automotive, and many others. With a steadfast commitment to quality, innovation, and customer satisfaction, {Company Name} has gained a reputation for delivering reliable and durable expansion bellow solutions. Employing a team of trained professionals and utilizing state-of-the-art manufacturing processes, the company ensures that its products meet the highest industry standards.Expansion Bellow Specification{Company Name} understands the diverse requirements of industrial applications and offers a comprehensive range of expansion bellows to suit various needs. The expansion bellow specification encompasses crucial design parameters and features that contribute to improved performance, longevity, and safety. Some of the key specifications are as follows:1. Material Selection: The expansion bellow material is chosen based on the specific application requirements. Common options include stainless steel, carbon steel, Hastelloy, Inconel, and other high-quality alloys. The selection is made considering factors such as temperature, pressure, corrosion resistance, and compatibility with process media.2. Size and Design: {Company Name} offers expansion bellows in a wide range of sizes and designs to accommodate different pipeline configurations. Whether it's a rectangular, circular, or other custom shapes, the company provides versatile options that can withstand high temperatures, pressures, and mechanical stress.3. Movement Capability: Expansion bellows are primarily employed to absorb movements caused by thermal expansion and contraction. The bellow specification includes parameters like axial, lateral, and angular movements to ensure that the bellows can handle the anticipated displacements in a given system.4. Pressure Ratings: To ensure structural integrity, expansion bellows must have adequate pressure ratings. {Company Name} manufactures expansion bellows with different pressure class ratings, enabling seamless integration within systems operating at varying pressures.5. Quality Testing: Prioritizing quality and reliability, {Company Name} subjects every expansion bellow to rigorous testing procedures. These include pressure tests, leak tests, fatigue cycle tests, and other non-destructive examinations to validate the performance and safety of the products.Benefits of {Company Name}'s Expansion Bellows{Company Name}'s expansion bellows offer several key benefits that make them an ideal choice for industrial applications:1. Flexibility: The expansion bellows' inherent flexibility allows them to absorb movement and minimize stress on adjoining components, thus preventing premature failure.2. Enhanced Safety: By effectively compensating for thermal expansion and contraction, expansion bellows ensure the integrity of pipelines, reduce the risk of leakage, and enhance overall operational safety.3. Improved Efficiency: Expansion bellows minimize the impact of vibration, misalignment, and thermal stresses on system components, resulting in smoother operation, increased efficiency, and reduced maintenance costs.4. Extended Lifespan: The high-quality materials and rigorous testing employed by {Company Name} contribute to the longevity of its expansion bellows, ultimately reducing the need for frequent replacements and associated downtime.ConclusionEmbracing the latest technological advancements and prioritizing customer satisfaction, {Company Name} provides expansion bellow solutions that meet the industry's demanding requirements. With a focus on safety, durability, and performance, the company ensures that its expansion bellows enable reliable operation for a wide range of industrial applications. For businesses seeking high-quality expansion bellows, {Company Name} remains a trusted and reliable partner.

Introducing a Revolutionary Threaded Union Rubber Expansion Joint: The Ultimate Solution for Enhanced Flexibility and Durability

Title: Innovative Threaded Union Rubber Expansion Joint Revolutionizing Industrial Piping SystemsIntroduction:In recent years, the demand for high-quality and efficient solutions in industrial piping systems has been increasing rapidly. To meet these demands, a leading company in the field of fluid transfer technology has introduced an innovative product – the Threaded Union Rubber Expansion Joint. This groundbreaking solution is set to revolutionize the industry, providing enhanced versatility, durability, and operational efficiency.1. Introduction to the Threaded Union Rubber Expansion Joint:The Threaded Union Rubber Expansion Joint is a highly engineered product designed to cater to the challenging requirements of modern industrial piping systems. It is manufactured using state-of-the-art technology and high-quality materials, ensuring its exceptional performance and longevity.2. Versatility in Applications:This versatile expansion joint finds applications in a wide range of industries, including chemical processing, petrochemicals, water treatment, power generation, and heating, ventilation, and air conditioning (HVAC) systems. Its adaptability to different piping configurations makes it an ideal choice for various projects.3. Benefits and Features:The Threaded Union Rubber Expansion Joint offers several significant benefits:a. Reduced Pipe Stress and Noise:The expansion joint absorbs vibrations, pipe movements, and thermal expansions, significantly reducing stress on connected equipment and minimizing noise levels. This enhances the overall operational efficiency and extends the lifespan of the entire piping system.b. Enhanced Flexibility:Designed with flexibility in mind, the expansion joint compensates for axial, lateral, and angular movements, ensuring optimal system performance even in challenging conditions.c. Superior Endurance:The high-quality rubber material used in the construction of this expansion joint enables it to withstand aggressive chemicals, extreme temperatures, and demanding operating conditions, guaranteeing long-term reliability.d. Easy Installation and Maintenance:With its user-friendly design and threaded union connection system, installation and maintenance processes are streamlined, minimizing downtime and resource requirements.e. Customizable Options:The Threaded Union Rubber Expansion Joint can be customized to meet specific requirements, including variations in size, pressure ratings, materials, and end connections, maximizing its suitability for a wide range of projects.4. Reducing Environmental Impact:The company is committed to sustainability and environmental responsibility. The Threaded Union Rubber Expansion Joint is designed to minimize leaks and prevent fugitive emissions, reducing the ecological impact of industrial processes and ensuring compliance with strict environmental regulations.5. Quality Assurance:The company adheres to stringent quality control measures and manufacturing standards, ensuring that each expansion joint meets the highest levels of performance, reliability, and safety. Stringent testing protocols are implemented throughout the manufacturing process to guarantee product excellence.6. Conclusion:The introduction of the Threaded Union Rubber Expansion Joint represents a significant advancement in industrial fluid transfer technology. Its innovative features, versatility, and durability make it a trusted choice for engineers and project managers seeking optimized performance and efficiency in a wide range of industrial applications. By prioritizing customer satisfaction, environmental responsibility, and quality assurance, the company sets new industry standards, cementing its position as an industry leader.In conclusion, the Threaded Union Rubber Expansion Joint is setting a new benchmark in the industrial piping systems market, providing a high-quality, versatile, and durable solution that meets the evolving demands of various industries.

Guide to Installing and Maintaining Expansion Joints for Piping Systems

Steel Pipe Expansion Joint: An Essential Component in Industrial Piping SystemsPiping systems are an integral part of any industrial plant or facility. They ensure the smooth flow of liquids, gases, and other substances through various processes and operations. However, as these substances move through the piping system, temperatures, pressure, and other factors can cause the pipes to expand or contract, leading to stress and damage.This is where expansion joints come in. Expansion joints are flexible connections that allow for movement in piping systems due to thermal expansion and contraction. They help prevent damage to pipes, fittings, and other components, while ensuring the safety and reliability of the entire system.Types of Expansion JointsThere are several types of expansion joints available for different applications. The most common types include:1. Bellows Expansion Joints: These are the most flexible type of expansion joints and are commonly used in high-temperature applications where thermal movement is significant.2. Metal Expansion Joints: These joints are constructed of metal plates, and their performance is dependent on the material used in their construction.3. Rubber Expansion Joints: These joints are made of rubber and are used in low-pressure applications, where temperature fluctuations are less severe.Installation and Maintenance of Expansion JointsProper installation and maintenance of expansion joints are crucial to ensuring their effectiveness and longevity. Here are some key steps to follow:1. Inspection Before Test: Before any testing, ensure that the expansion joint is properly installed, and all components are correctly aligned. Check for any signs of damage or defects.2. Inspection During and After Test: During testing, visually inspect the expansion joint for any signs of leaks or movement. After testing, inspect the joint again to ensure that it has returned to its original position.3. Periodic In-service Inspections: Regularly inspect the expansion joint for any signs of wear and tear. This includes checking the bellows for any signs of fatigue, such as cracks or corrosion.4. System Upgrades: When upgrading or modifying the piping system, ensure that the expansion joint remains compatible and can accommodate any changes in temperature, pressure, or flow.Benefits of Steel Pipe Expansion JointsSteel pipe expansion joints are an ideal solution for high-temperature applications and corrosive environments. They offer the following benefits:1. High Temperature Resistance: Steel expansion joints can withstand high temperatures, making them ideal for use in industrial boilers, furnaces, and other high-temperature equipment.2. Corrosion Resistance: Steel expansion joints are resistant to corrosion and rust, making them suitable for use in highly corrosive environments.3. Longevity: Steel expansion joints have a long service life and require minimal maintenance.4. Versatility: Steel expansion joints are available in a variety of sizes and configurations to suit specific piping system requirements.ConclusionSteel pipe expansion joints are an essential component in industrial piping systems, ensuring the safety, reliability, and longevity of the entire system. Proper installation and maintenance are critical to their effectiveness, and regular inspections can prevent costly repairs and downtime. As always, it is important to consult with a qualified engineer or supplier to ensure that the right expansion joint is selected for each specific application.

Discover the Advantages of Rubber Expansion Joints in the Philippines

[Title]: Rubber Expansion Joint Market in the Philippines Poised for Significant Growth[Subtitle]: Market Leaders Aiming to Cater to Increasing Infrastructure Projects[date][Location]: PhilippinesIn recent years, the demand for rubber expansion joints in the Philippines has experienced significant growth due to a surge in infrastructure developments across the country. Companies within the industry are actively working to meet this rising demand by expanding their production capabilities.One of the leading players in the rubber expansion joint market, [Company Name], has been at the forefront of this expansion. Founded [X] years ago, [Company Name] has established itself as a trusted supplier and manufacturer of high-quality rubber expansion joints, catering to a wide range of industries, including construction, oil and gas, water management, and power generation.[Company Name] boasts a state-of-the-art manufacturing facility equipped with advanced technologies and a team of highly skilled engineers and technicians who adhere to international standards. The company takes pride in its commitment to delivering innovative and customized solutions that meet the specific needs of its clients, ensuring utmost customer satisfaction.The escalating demand for rubber expansion joints in the Philippines is closely tied to the government's drive to enhance infrastructure development and stimulate economic growth. The current administration has made significant investments in large-scale projects such as highways, bridges, ports, and airports, creating a favorable market landscape for companies like [Company Name].Rubber expansion joints play a vital role in these infrastructure projects by providing flexibility and absorption of movement, ensuring structural integrity and preventing damage caused by natural forces such as earthquakes, thermal expansion, or vibrations. Additionally, they act as a shock absorber, minimizing the impact on adjacent structures and components.With a vision to enhance the quality and durability of rubber expansion joints in the market, [Company Name] has consistently invested in research and development activities. This has resulted in the creation of advanced manufacturing processes and the adoption of cutting-edge materials that offer superior performance and longevity.Moreover, [Company Name] has also focused on environmental sustainability. By utilizing eco-friendly materials and implementing energy-efficient production methods, the company aims to minimize its impact on the environment throughout the entire product lifecycle.Recognizing the importance of customer support, [Company Name] provides comprehensive after-sales services, attending to maintenance, inspections, and repairs as required. This commitment to post-installation support has earned the company a strong reputation for reliability and dependability in the market.In addition to [Company Name], other local and international manufacturers have also recognized the potential of the Philippine market and have begun expanding their operations to fulfill the growing demand for rubber expansion joints. The increased competition has led to more innovative solutions, driving advancements in technology, design, and performance within the industry.The rubber expansion joint market in the Philippines is projected to witness a steadfast growth trajectory in the coming years. According to market analysts, the increasing infrastructure expenditures and ongoing government initiatives will continue to serve as major drivers of the market.Major challenges, such as the fluctuations in raw material prices and intensifying competition, prompt companies like [Company Name] to maintain their edge through continuous innovation and by exploring new market avenues. Developing economies, such as the Philippines, are expected to create lucrative opportunities for the rubber expansion joint industry to thrive further.In conclusion, with the surge in infrastructure projects across the Philippines, the demand for rubber expansion joints is set to grow significantly. Leading companies such as [Company Name] are actively expanding their production capabilities to cater to this increasing demand. By providing innovative products, superior customer support, and a focus on sustainability, [Company Name] is well-positioned to capitalize on the evolving market landscape. As the market continues to thrive, the rubber expansion joint industry in the Philippines holds great potential for both local and international players. The collaboration between infrastructure projects and rubber expansion joint manufacturers promises a bright future for the country's construction and industrial sectors.Word Count: 800 words.

Rubber Flexible Bellows: A Comprehensive Guide to Their Uses and Benefits

Rubber Flexible Bellows: Revolutionizing Industrial Applications[Company Name], a leading manufacturer in the rubber industry, has recently introduced a groundbreaking product known as Rubber Flexible Bellows. With an unwavering commitment to innovation and quality, [Company Name] has revolutionized the world of industrial applications with this cutting-edge solution.Rubber Flexible Bellows, as the name suggests, are bellows made from high-quality rubber materials. These flexible components serve a crucial role in numerous industries, including manufacturing, automotive, aerospace, and construction. By providing protection against dust, debris, moisture, and vibrations, Rubber Flexible Bellows are a key component in safeguarding machinery and equipment from potential damage.The superior performance of Rubber Flexible Bellows can be attributed to their inherent properties. The rubber material used in their construction exhibits exceptional durability, flexibility, and resistance to a wide range of environmental factors. This ensures that the bellows can withstand demanding operating conditions, offering long-lasting protection to the machinery they are installed on.One of the key advantages of Rubber Flexible Bellows is their ability to accommodate various types of movement. As machinery operates, there are often dynamic motions, such as expansion, contraction, or angular displacement. Rubber Flexible Bellows can effortlessly absorb and accommodate these movements, allowing for smooth and uninterrupted functioning of the equipment. This versatility makes them an ideal choice for a wide range of industrial applications.In addition to their flexibility, Rubber Flexible Bellows also excel in providing efficient sealing and insulation. Thanks to their unique design and high-quality rubber material, they create a tight seal around moving parts, preventing the entry of contaminants and ensuring the longevity of the machinery. Moreover, these bellows also provide effective insulation against noise, heat, and vibration, creating a safer and more comfortable working environment.With safety being a top priority in any industrial setting, Rubber Flexible Bellows play a crucial role in protecting both machinery and personnel. The efficient insulation properties of these bellows help in reducing noise levels, preventing hearing damage and enhancing overall comfort for workers. Furthermore, by minimizing heat transfer and vibration transmission, Rubber Flexible Bellows contribute to the prevention of accidents and injuries.[Company Name] has earned a stellar reputation in the industry for its commitment to delivering high-quality products. The Rubber Flexible Bellows undergo rigorous quality control procedures, ensuring that each unit meets the highest standards. Additionally, the company's dedicated research and development team continually strives to improve the design and performance of the bellows, staying at the forefront of technological advancements.The versatility of Rubber Flexible Bellows is further amplified by their customization options. [Company Name] offers a wide range of sizes, shapes, and materials to cater to the specific needs of different industries and applications. The company's team of experts works closely with clients to understand their requirements and provides tailored solutions that maximize efficiency and performance.As a frontrunner in the rubber industry, [Company Name] continues to set new benchmarks for excellence. The introduction of Rubber Flexible Bellows reinforces the company's commitment to innovation and customer satisfaction. By delivering a reliable and cost-effective solution, [Company Name] enables businesses to enhance their productivity, minimize downtime, and extend the lifespan of their machinery.In conclusion, Rubber Flexible Bellows offered by [Company Name] have revolutionized the industrial landscape. With exceptional durability, flexibility, and sealing properties, these bellows effectively protect machinery from damage caused by environmental factors. By absorbing various types of movement and providing efficient insulation, Rubber Flexible Bellows create a safer and more productive work environment. Through their dedication to quality and customization, [Company Name] continues to lead the way in delivering cutting-edge solutions for industrial applications.

Insightful Updates Delves into the World of Bellows by Expert Authors - Johnball2014, Exaircorp, and Joe Panfalone

Metallic Bellows Design: Key Considerations for Successful ApplicationsBellows are essential components in many industrial applications, where they provide flexibility, reliability, and durability. Metallic bellows, in particular, offer superior performance in demanding environments where high-pressure, high-temperature, and corrosive fluids are present. However, designing a metallic bellows requires careful consideration of various factors, including material selection, geometry, performance parameters, and manufacturing processes. In this blog, we will explore some key considerations for successful metallic bellows design.Material selection: The choice of material for a metallic bellows depends on the intended application and the operating conditions. Typically, metallic bellows are made of alloys such as stainless steel, Inconel, Hastelloy, or titanium. Stainless steel is the most commonly used material due to its excellent corrosion resistance, thermal stability, and affordability. Inconel and Hastelloy, on the other hand, offer superior resistance to high temperature, acids, and alkalis, making them ideal for critical applications in the chemical, petrochemical, and aerospace industries. Titanium is suitable for applications that require high strength, low weight, and biocompatibility.Geometry: The geometry of a metallic bellows determines its flexibility, pressure capacity, and fatigue life. A typical bellows consists of a series of convolutions that allow it to expand and compress axially, while maintaining a constant volume. The number, pitch, height, and wall thickness of the convolutions influence the bellows' performance parameters, such as stroke, spring rate, and cycle life. Bellows with fewer convolutions have higher stiffness, while those with more convolutions have higher flexibility. Bellows with thicker walls have higher pressure capacity but lower flexibility. The pitch and height of the convolutions determine the bellows' axial stroke and displacement.Performance parameters: The performance parameters of a metallic bellows include stroke, cycle life, pressure capacity, leak tightness, and vibration resistance. Stroke refers to the axial displacement of the bellows under an external load. Cycle life refers to the number of cycles the bellows can withstand before failure due to fatigue. Pressure capacity refers to the maximum pressure the bellows can withstand without permanent deformation or rupture. Leak tightness refers to the bellows' ability to maintain a seal against gas or fluid leakage. Vibration resistance refers to the bellows' ability to withstand dynamic loads without fatigue failure.Manufacturing processes: The manufacturing processes for metallic bellows involve several steps, including cutting, forming, welding, and testing. The cutting process involves trimming the raw material to the correct size and shape. The forming process involves shaping the material into the desired convolution geometry using hydraulic or mechanical dies. The welding process involves joining the convolutions together using either TIG or laser welding. Finally, the testing process involves verifying the bellows' performance parameters using various methods, such as hydrostatic testing, vacuum testing, or fatigue testing.In conclusion, designing a metallic bellows requires careful consideration of various factors, including material selection, geometry, performance parameters, and manufacturing processes. By selecting the appropriate materials, optimizing the geometry, ensuring the desired performance parameters, and using reliable manufacturing processes, you can achieve a successful metallic bellows design that meets your application's specific requirements. At (company name), we specialize in designing and manufacturing high-quality metallic bellows for a wide range of applications, from aerospace and defense to medical and semiconductor. Contact us today to learn more about how we can help you with your metallic bellows design needs.

Certification for Quality Fluorine Elastomer Expansion Joints with Genuine Viton

Maintenance and Durability in Heavy-duty ApplicationsWhen it comes to industrial equipment, heavy-duty applications require the strongest and most reliable materials available. This is especially important for equipment used in power stations, flue-gas desulfurization plants, and other high-stress environments that need to withstand extreme heat, pressure, and vibration. In order to ensure optimal performance and long-lasting durability, expansion joints made with elastomers have become a staple in the industry.Elastomer expansion joints are flexible connectors that are designed to absorb movements, vibrations, and stress caused by machinery and piping systems. They also protect equipment from structural damage and reduce noise and emissions. The most common types of elastomers used in expansion joints are natural rubber, neoprene, EPDM, and Viton.Viton, in particular, is a high-performance elastomer that is known for its exceptional resistance to heat, chemicals, and fluids. It is widely used in aerospace, automotive, pharmaceutical, and industrial applications, where it is critical to maintain strict quality control standards. Genuine Viton is a trademarked product of DuPont, and is recognized as the gold standard in terms of quality and reliability.Expansion joints made with genuine Viton have several advantages over other types of elastomers. Firstly, they can withstand temperatures between -20 to 204°C, making them ideal for use in extreme weather conditions. Additionally, they are highly resistant to corrosive gases and liquids, which can cause damage to other materials over time. This is especially important in power stations, where flue gases contain sulfur dioxide and other acidic compounds that can erode and degrade equipment.Another significant advantage of genuine Viton expansion joints is their exceptional durability. Unlike other elastomers that may last only a few years before needing replacement, genuine Viton expansion joints can have a working life of up to ten years or more. This means fewer replacement and maintenance costs in the long run, as well as reduced downtime and increased productivity.When selecting expansion joints for heavy-duty applications, it is important to choose a reputable manufacturer who can guarantee the quality and performance of their products. Power Engineering International Company is certified by DuPont to use genuine Viton in their flue-gas desulfurization plants, ensuring that their expansion joints meet the highest standards of reliability and durability. They are also RAL-awarded for quality and ISO 9001 certified.Maintenance of elastomer expansion joints is critical for ensuring their longevity and performance. Regular visual inspections for signs of leaks, cracks, or wear and tear are recommended, as well as periodic cleaning to remove dust, dirt, and debris. It is also essential to follow the manufacturer's instructions for installation, operation, and maintenance, to ensure optimal performance and minimize any potential sources of failure.In conclusion, elastomer expansion joints are an essential component of heavy-duty machinery and piping systems in power stations, flue-gas desulfurization plants, and other industrial applications. Genuine Viton expansion joints offer superior resistance to heat, chemicals, and fluids, as well as exceptional durability and longevity. Selecting high-quality expansion joints and following proper maintenance procedures can ensure optimal performance and minimize maintenance costs in the long run.