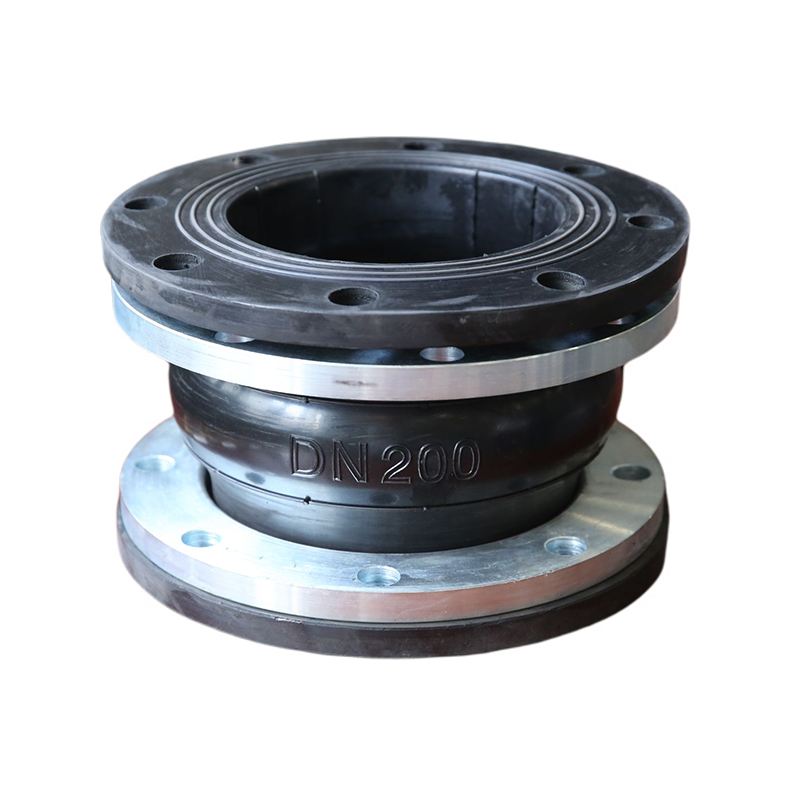

Durable and Flexible Single Arch Rubber Expansion Joint

By:Admin

With a high demand for reliable and efficient expansion joints, (Company) has emerged as a leading manufacturer and supplier in the industry. The company has established a strong reputation for producing top-quality rubber expansion joints that meet the highest standards of performance and durability.

The single arch rubber expansion joint offered by (Company) is designed to accommodate a variety of piping systems, including water treatment plants, power generation facilities, chemical plants, and HVAC systems. The expansion joint is constructed from high-grade rubber material, which provides excellent resistance to corrosion, chemicals, and extreme temperatures. This ensures that the expansion joint can withstand harsh environmental conditions and provide long-term reliability.

The single arch design of the expansion joint allows for easy installation and maintenance, making it an ideal choice for various applications. The rubber material also allows for flexibility and movement in the piping system, which helps to minimize stress and fatigue on the pipelines. This ultimately extends the lifespan of the entire piping network and reduces the need for frequent repairs and replacements.

One of the key features of (Company)'s single arch rubber expansion joint is its ability to absorb noise and vibration in the piping system. This is particularly important in industrial settings where excessive noise and vibration can affect the performance and safety of the equipment. The expansion joint effectively dampens these disturbances, creating a quieter and smoother operation.

In addition, the rubber expansion joint helps to minimize the risk of leakage and structural damage in the piping system. Its flexibility and ability to absorb movement and pressure fluctuations prevent the development of cracks and leaks, ensuring the integrity of the entire system. This is crucial for maintaining a safe and efficient operation in various industrial and commercial settings.

Furthermore, (Company) takes pride in its commitment to quality and customer satisfaction. The single arch rubber expansion joint undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards. This dedication to excellence has earned (Company) a strong reputation for reliability and trustworthiness among its customers.

The expansion joint is available in a range of sizes and configurations to suit different project requirements. (Company)'s team of experts is also available to provide custom solutions and technical support to address specific needs and challenges. This level of flexibility and expertise sets (Company) apart as a preferred partner for expansion joint solutions.

In conclusion, (Company) has demonstrated expertise and innovation in the manufacturing of single arch rubber expansion joints. With a focus on quality, reliability, and customer satisfaction, the company continues to be a trusted name in the industry. Its expansion joints are designed to provide long-term performance, durability, and safety in various piping systems, making them an ideal choice for construction and industrial applications.

Company News & Blog

Ultimate Guide to Pump Flexible Joints: What You Need to Know

Pump Flexible Joint, a key component in the machinery industry, has become an essential product in various industrial applications. It has the capability to absorb vibration, reduce noise, and compensate for misalignment, thereby contributing to the smooth operation of different types of pumps. As a leading manufacturer of these crucial components, {Company Name} has been at the forefront of delivering high-quality and innovative solutions to meet the unique needs of its clients.{Company Name} was established in the early 2000s with a mission to provide top-notch pump accessories and components to businesses worldwide. With a strong emphasis on research and development, the company has continuously strived to enhance its product line and develop new technologies that align with the evolving needs of the industry. This commitment has enabled {Company Name} to gain a strong foothold in the market and establish itself as a trusted and reliable supplier of pump flexible joints.The pump flexible joints manufactured by {Company Name} are engineered to withstand the rigors of industrial environments. They are made from high-quality materials, ensuring durability and longevity. Moreover, the company’s dedication to quality control and testing procedures guarantees that each flexible joint meets stringent industry standards and specifications.One of the key features of {Company Name}’s pump flexible joints is their flexibility and adaptability. They are designed to accommodate a wide range of movements and vibrations, making them suitable for various types of pumps and piping systems. This versatility has made {Company Name} a preferred choice for businesses looking for reliable and cost-effective solutions for their pumping needs.In addition to its product quality, {Company Name} is also known for its exceptional customer service. The company’s team of experts is committed to providing comprehensive support to clients, from selecting the right flexible joint for their specific requirements to offering technical assistance and guidance throughout the installation and maintenance processes.As the demand for pump flexible joints continues to grow, {Company Name} has been proactive in expanding its production capacity and optimizing its manufacturing processes. The company has invested in advanced machinery and technology to enhance efficiency and productivity, allowing it to fulfill large orders and meet tight deadlines without compromising on quality.Furthermore, {Company Name} has been dedicated to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, from sourcing raw materials to waste management, to minimize its ecological footprint. This commitment to sustainability has not only earned {Company Name} a positive reputation in the industry but has also contributed to its long-term success and growth.Looking ahead, {Company Name} is poised to continue its trajectory of success in the market for pump flexible joints. The company remains focused on innovation and diversification, exploring new opportunities and partnerships to further expand its product offerings and reach new markets. With a steadfast commitment to excellence and customer satisfaction, {Company Name} is set to remain a leader in the industry and a go-to choice for businesses seeking reliable pump accessories and components.In conclusion, {Company Name} has etched its name as a pioneer in the manufacturing of pump flexible joints, setting industry standards for quality, reliability, and innovation. With a strong focus on customer satisfaction, sustainability, and continuous improvement, the company is well-positioned to meet the evolving needs of the market and maintain its position as a key player in the industry.

Rubber Expansion Joint for High-Pressure Pipeline Connections

In today's industrial landscape, pipelines play a significant role in ensuring smooth operations in different sectors. One aspect that demands attention while setting up pipelines is the flexibility and durability required to withstand harsh conditions. This is where flexible rubber expansion joints come into the picture.One of the industry leaders in the manufacture and supply of rubber expansion joints is the JGD-A Double-Sphere Rubber Expansion Joint, manufactured by (need remove brand name). This product is designed to deliver high levels of elasticity, pressure sealing, and weather resistance to ensure uninterrupted operations in pipelines.The Double-Sphere Rubber Expansion Joint is an essential addition to any pipeline system as it absorbs vibration, noise, and shock, thereby reducing the risk of any damage to the pipeline. By increasing flexibility, these rubber expansion joints significantly reduce the intensity of hydraulic shock and prolonged vibration. Hence, they help prevent the premature failure of pipelines caused by fatigue, corrosion, and damage.Manufactured using premium materials, the Double-Sphere Rubber Expansion Joint is designed to be highly resistant to wear and tear, corrosion, and harsh chemicals, making it an invaluable component for numerous applications. The product is designed to cover a wide range of operating temperatures and pressures, making it ideal for use in different industries, including chemical processing, power generation, water treatment, and mining, among others.One of the key features of the JGD-A Double-Sphere Rubber Expansion Joint is its easy installation process, which makes it a cost-effective solution for pipe system maintenance. Additionally, this product's high-pressure capabilities make it ideal for use in high-demand applications, making it an essential component for different pipeline systems.The Double-Sphere Rubber Expansion Joint is made with a uniq

Comprehensive Guide to Expansion Bellow Specifications for Industrial Applications

Expansion Bellow Specification for Improved Performance and Safety in Industrial ApplicationsDate:In today's rapidly evolving industrial sector, the demand for high-performance equipment and systems continues to grow. One crucial component that plays a significant role in ensuring the smooth functioning of various industrial processes is expansion bellows. These flexible devices are designed to absorb thermal expansion and contraction, vibrations, and misalignments in pipelines, thereby preventing damage to critical infrastructure and improving overall safety.Company Introduction{Company Name} is a leading manufacturer and supplier of expansion bellows, catering to a wide range of industries such as oil and gas, petrochemical, power generation, water treatment, automotive, and many others. With a steadfast commitment to quality, innovation, and customer satisfaction, {Company Name} has gained a reputation for delivering reliable and durable expansion bellow solutions. Employing a team of trained professionals and utilizing state-of-the-art manufacturing processes, the company ensures that its products meet the highest industry standards.Expansion Bellow Specification{Company Name} understands the diverse requirements of industrial applications and offers a comprehensive range of expansion bellows to suit various needs. The expansion bellow specification encompasses crucial design parameters and features that contribute to improved performance, longevity, and safety. Some of the key specifications are as follows:1. Material Selection: The expansion bellow material is chosen based on the specific application requirements. Common options include stainless steel, carbon steel, Hastelloy, Inconel, and other high-quality alloys. The selection is made considering factors such as temperature, pressure, corrosion resistance, and compatibility with process media.2. Size and Design: {Company Name} offers expansion bellows in a wide range of sizes and designs to accommodate different pipeline configurations. Whether it's a rectangular, circular, or other custom shapes, the company provides versatile options that can withstand high temperatures, pressures, and mechanical stress.3. Movement Capability: Expansion bellows are primarily employed to absorb movements caused by thermal expansion and contraction. The bellow specification includes parameters like axial, lateral, and angular movements to ensure that the bellows can handle the anticipated displacements in a given system.4. Pressure Ratings: To ensure structural integrity, expansion bellows must have adequate pressure ratings. {Company Name} manufactures expansion bellows with different pressure class ratings, enabling seamless integration within systems operating at varying pressures.5. Quality Testing: Prioritizing quality and reliability, {Company Name} subjects every expansion bellow to rigorous testing procedures. These include pressure tests, leak tests, fatigue cycle tests, and other non-destructive examinations to validate the performance and safety of the products.Benefits of {Company Name}'s Expansion Bellows{Company Name}'s expansion bellows offer several key benefits that make them an ideal choice for industrial applications:1. Flexibility: The expansion bellows' inherent flexibility allows them to absorb movement and minimize stress on adjoining components, thus preventing premature failure.2. Enhanced Safety: By effectively compensating for thermal expansion and contraction, expansion bellows ensure the integrity of pipelines, reduce the risk of leakage, and enhance overall operational safety.3. Improved Efficiency: Expansion bellows minimize the impact of vibration, misalignment, and thermal stresses on system components, resulting in smoother operation, increased efficiency, and reduced maintenance costs.4. Extended Lifespan: The high-quality materials and rigorous testing employed by {Company Name} contribute to the longevity of its expansion bellows, ultimately reducing the need for frequent replacements and associated downtime.ConclusionEmbracing the latest technological advancements and prioritizing customer satisfaction, {Company Name} provides expansion bellow solutions that meet the industry's demanding requirements. With a focus on safety, durability, and performance, the company ensures that its expansion bellows enable reliable operation for a wide range of industrial applications. For businesses seeking high-quality expansion bellows, {Company Name} remains a trusted and reliable partner.

Flexible Rubber Pump Connectors Offer Highly Effective Pumping Solution for Various Industrial Applications

Rubber Flexible Pump Connectors Set to Revolutionize the Pumping IndustryRubber flexible pump connectors are the latest innovation in the pumping industry, which is poised to take the industry by storm. These connectors are designed to connect pumps, tanks, and pipelines seamlessly, effectively reducing the likelihood of damage or wear and tear.The product is manufactured by a reputable company that has been in the business of making high-quality industrial products for several years. The manufacturers have used a combination of high-quality materials, advanced technology, and expertise to create a product that is superior in terms of performance, durability, and reliability.Rubber flexible pump connectors are specifically designed to withstand high-pressure pumping applications, making them an ideal choice for a range of industries such as mining, oil and gas, chemical processing, and water treatment. These connectors are highly flexible, which means that they can easily adapt to any shape or size of the pipe or tank they are connected to.The design and construction of these connectors ensure that they can withstand high temperatures, chemicals, and abrasive materials commonly found in industrial settings. As such, they can be used in a wide range of applications, including pumping slurries, chemicals, and other abrasive materials.The use of rubber flexible pump connectors offers several benefits to the pumping industry. One of the most significant advantages of these connectors is that they help to reduce noise and vibration levels. By dampening vibrations, they help to prevent equipment damage and improve the lifespan of equipment.Another benefit of using rubber flexible pump connectors is that they help to ensure that pipelines and tanks remain leak-free. The connectors are designed to seal the connection between two pipes or tanks, significantly reducing the likelihood of leaks or spills. This, in turn, helps to prevent environmental damage and reduces the risk of accidents.Rubber flexible pump connectors are also easy to install and do not require any special tools or equipment. They can be easily installed by a qualified technician, which helps to save time and money.In addition to these benefits, the manufacturers of rubber flexible pump connectors have also ensured that their product is cost-effective. Unlike other types of connectors that need to be replaced frequently due to wear and tear, rubber flexible pump connectors are designed to last for a long time, reducing the need for frequent replacements. This, in turn, helps to save money in the long run.Overall, rubber flexible pump connectors offer a range of benefits to the pumping industry, making them an ideal choice for anyone looking for a reliable and efficient pumping solution. Whether you are working in the mining industry or the chemical processing industry, these connectors are sure to make your work easier and more efficient.In summary, rubber flexible pump connectors are the latest innovation in the pumping industry. Manufactured by a reputable company with years of experience in the industry, these connectors are designed to improve efficiency, reduce noise and vibration levels, prevent leaks, and save money. They are an ideal choice for anyone looking for a reliable and efficient pumping solution.

Understanding the Concept of Pipe Thermal Expansion

Pipe Thermal Expansion is a critical issue that affects various industries, including the oil and gas, chemical, and power generation sectors. It occurs when pipes are subjected to temperature changes, causing them to expand and contract, which can lead to significant damage if not properly managed. One company that specializes in providing effective solutions for mitigating pipe thermal expansion is {}. With a long-standing reputation for delivering high-quality products and services, the company has become a trusted partner for numerous clients facing challenges related to thermal expansion in their piping systems.Established over two decades ago, {} has continued to evolve and innovate, staying at the forefront of technological advancements in the field of pipe thermal expansion. The company’s team of dedicated engineers and technicians are deeply knowledgeable about the complexities of thermal expansion and are committed to developing tailored solutions to meet their clients’ specific needs.{}’s comprehensive range of products includes expansion joints, bellows, and other specialized components designed to accommodate thermal movement within piping systems. These products are engineered to withstand extreme temperatures, pressures, and corrosive environments, ensuring the longevity and reliability of the piping infrastructure.In addition to its exceptional product offerings, {} also provides a variety of services aimed at assisting clients in effectively managing pipe thermal expansion. This includes on-site inspections, system evaluations, and custom design solutions to address specific expansion challenges. The company’s expertise in thermal expansion allows clients to have peace of mind, knowing that their piping systems are in capable hands.Recently, {} has made significant advancements in the field of pipe thermal expansion, introducing new technologies and materials that further enhance the performance and durability of their products. These innovations have been well-received by clients, who have reported improvements in the efficiency and safety of their piping systems after implementing {}’s solutions.One of the key factors contributing to {}’s success is their commitment to customer satisfaction and their ability to provide tailored solutions to address unique thermal expansion challenges. By working closely with clients to understand their specific requirements, the company is able to deliver customized products and services that effectively mitigate the risks associated with thermal expansion.Furthermore, {} places a strong emphasis on quality assurance, ensuring that every product that leaves their facilities meets the highest standards of performance and reliability. This dedication to quality has earned the company numerous certifications and accreditations, further solidifying their reputation as a leading provider of thermal expansion solutions.Looking ahead, {} is poised to continue making significant contributions to the field of pipe thermal expansion, as they remain dedicated to research and development efforts that drive innovation. By staying ahead of industry trends and technological advancements, the company is well-positioned to meet the evolving needs of their clients and continue providing cutting-edge solutions for thermal expansion challenges.In conclusion, pipe thermal expansion is a critical consideration for industries that rely on piping systems, and {} has established itself as a trusted partner in providing effective solutions. With a proven track record of delivering high-quality products and services, the company is well-equipped to meet the unique thermal expansion challenges faced by their clients. As they continue to innovate and evolve, {} is set to remain a leader in the field of pipe thermal expansion for years to come.

Flourine Elastomer Expansion Joints Receive DuPont Certification for Genuine Viton Usage

Power Engineering International Company, known for its expertise in manufacturing high-quality expansion joints for various industries, has recently received DuPont certification to use genuine Viton for its flouorine elastomer expansion joints. This move puts Power Engineering International ahead of its competitors, as it now has the seal of approval for its product quality.Expansion joints are essential components in industries that handle high-pressure fluids and gases. These components are especially critical in power stations, where they are used in flue-gas desulfurization plants. These plants operate in harsh environments, working round the clock and exposed to high temperatures, abrasive materials, and pressure changes. Any malfunction of an expansion joint can cause catastrophic damage to equipment and personnel, leading to downtime and lost productivity."Made with Genuine Viton" CertificationViton expansion joints meet the rigorous demands of flue-gas desulfurization plants in power stations, with many working hours of over 50,000. These high-performing expansion joints typically have a life cycle of between five to ten years. Viton is a fluoroelastomer material known for its exceptional resistance to harsh chemical environments, high temperatures, and pressure changes, making it the ideal material for use in power stations.The "Made with Genuine Viton" certification is proof of quality, and Power Engineering International Company has now earned this seal of approval. The certification verifies that the company uses genuine Viton material in its expansion joints. The certification adds another feather to the company's cap, as it already boasts the 1990 RAL-awarded quality mark for expansion joints and ISO 9001 certification.Research and DevelopmentPower Engineering International Company has a long-standing reputation for producing high-quality expansion joints that meet industry standards. The company has invested heavily in research and development to produce innovative products that meet everchanging market needs. Power Engineering International employs a team of highly qualified engineers and technicians who work tirelessly to improve product performance and reduce downtime.The company's state-of-the-art laboratory, equipped with modern testing equipment, enables the team to conduct various tests, including non-destructive testing, life cycle tests, and performance tests. The rigorous testing ensures that the products meet the highest quality standards before they reach the market.Customer ServicePower Engineering International values customer satisfaction and has put in place measures to ensure they meet their customers' expectations. With many years of experience in the industry, the company understands the needs of its customers. The company's sales team is knowledgeable and experienced, providing technical assistance to customers to identify the most suitable products for their needs. The team also assists customers with installation and maintenance of the expansion joints. This customer-focused approach has earned Power Engineering International Company a loyal customer base, with many customers returning for repeat purchases.ConclusionThe certification from DuPont to use genuine Viton for its flouorine elastomer expansion joints strengthens Power Engineering International's position as a leader in the industry. The certification shows the company's commitment to producing high-quality products that meet industry standards. The company's investment in research and development, state-of-the-art laboratory, and focus on customer satisfaction has earned it a reputation for excellence in the industry, and it is well-positioned to continue leading the way.

How to Prevent Pipe Damage from Thermal Expansion

As industries continue to evolve and expand, there is an increasing need for innovative solutions that can effectively address and solve problems faced during construction, maintenance, and production activities. One such solution that has been gaining increasing popularity in recent times is pipe thermal expansion. A method that concerns the force behind the expansion or contraction of materials through temperature fluctuations.One of the companies that have been leading the way in offering such innovative solutions is the renowned industry leader in manufacturing and installation of thermal expansion systems. Their technology not only delivers practical and efficient solutions but also helps to reduce operational costs, increase safety, and improve reliability.Thermal expansion happens when materials or structures expand or contract due to temperature fluctuations. For instance, when heated, a pipe expands and can either crack or leak if the expansion occurs beyond the pipe's capacity. This is where the thermal expansion system comes into play, its the ability to allow pipe expansion and contraction without undue stress, which ultimately saves the pipe from damages.The expansion of pipes is one of the significant issues that industries face in production. Thus, many companies have turned towards pipe thermal expansion solutions to increase the life span of their pipeline infrastructure systems. Construction, refinery, chemical, and other industries can benefit from the non-disruptive nature of the thermal expansion system offered by the company. The system ensures that the pipelines maintain their integrity and helps to prevent leaks and damages.Apart from reducing pipeline damages and disruptions, the thermal expansion technology also helps in the transportation of liquids through pipelines over long distances. The ability to expand or contract the pipes allows for the efficient delivery and transport of liquids and gaseous substances, which is vital in the modern industrial landscape.Additionally, the company's thermal expansion technology provides a suitable alternative to traditional pipeline insulation. Traditional insulation methods can increase energy consumption, and in turn, increase cost significantly. With pipe thermal expansion, pipes can expand and contract without undue stress while maintaining the required temperature, ultimately leading to a reduction in energy consumption.One of the significant benefits of the company's thermal expansion technology is its versatility. It is ideal for use in various pipeline infrastructure systems and applications such as underground piping, petroleum refineries, water treatment plants and many more. Additionally, the technology can function under a wide range of atmospheric and environmental conditions, thus making it an ideal solution for industries in various regions.In conclusion, the modern industrial landscape requires innovative solutions that can help to improve overall efficiency and productivity. The developmental efforts made by the company in the area of pipe thermal expansion have long term benefits, including increasing structural integrity, limiting unexpected downtime, increasing profitability, and protecting the environment. As industries continue to evolve at a rapid pace, the solution offered by the company is one of the critical drivers for industrial progress.

Discover the Versatility and Benefits of Flexible Rubber in Various Industries

Flexibility is a highly valued attribute in many aspects of life and business. Whether it be in the workplace, sports or other physical activities, having a flexible approach can help us navigate challenges and reach our goals. The same can be said for the materials that we use in our daily lives, including rubber. A new innovation in the rubber industry promises to deliver even greater flexibility and versatility than ever before.Flexible Rubber is a new type of rubber material that has been developed by a leading materials science company. This proprietary material is made using a combination of advanced manufacturing techniques, including a unique blending process that allows for the creation of a highly flexible and versatile rubber compound. This material has a wide range of potential applications, from automotive components to consumer products.One of the key features of Flexible Rubber is its ability to withstand significant levels of stress and strain without breaking or degrading. This means that it is ideal for use in high-performance applications such as engine components, where it can deliver improved durability and performance under difficult conditions. The material is also highly resistant to abrasion and wear, making it suitable for use in products that are subjected to regular use and abuse.In addition to its strength and durability, Flexible Rubber also offers a number of other benefits. It is highly resistant to temperature extremes, meaning that it can be used in a wide range of environments and applications without experiencing degradation. The material is also highly flexible, meaning that it can be shaped into a variety of different forms and shapes.One area where Flexible Rubber has shown particular promise is in the production of consumer products. The material is highly versatile, meaning that it can be used in a wide range of applications, from toys to household goods. Its flexibility and durability make it ideal for use in products that require a combination of strength and flexibility, such as phone cases or sports equipment.The development of Flexible Rubber is a testament to the ongoing innovation and research in the materials science industry. By combining advanced manufacturing techniques with cutting-edge materials, companies can create materials that offer unprecedented levels of performance and versatility.The company behind Flexible Rubber is known for its expertise in the development of advanced materials. With a focus on innovation and research, the company has established itself as a leader in the field of materials science, developing materials that offer improved performance, durability, and sustainability.One aspect of the company's mission is to create materials that are not only high-performing but also environmentally friendly. Flexible Rubber is no exception. The material is made using a range of sustainable manufacturing techniques and is designed to be recycled at the end of its useful life. This focus on sustainability is becoming increasingly important as consumers and businesses alike look for ways to reduce their environmental impact.In conclusion, Flexible Rubber is an exciting new development in the world of materials science. This highly flexible and versatile material offers a range of benefits, from improved durability and performance to versatility and sustainability. With its wide range of potential applications, Flexible Rubber is poised to have a major impact on a variety of industries, from automotive to consumer products. As innovation in materials science continues to drive progress, it is exciting to think about the possibilities that materials like Flexible Rubber will bring in the future.

Expert Assembly of Hydraulic and Pneumatic Systems In-House, Including Rare Components

and Air Hydro Power.As industries continue to evolve, the demand for highly advanced machinery and equipment rises. Among these machines and equipment, there is one vital component that allows for smooth and efficient operation – hydraulic expansion joints.At Air Hydro Power, we specialize in providing high-quality hydraulic expansion joints that cater to the needs of various industries. We take pride in our expertise in building each assembly in-house, using only the best materials available in the market.What are hydraulic expansion joints?Before discussing the benefits of hydraulic expansion joints, it is essential to understand what they are, how they work, and their different types.Hydraulic expansion joints are essential components of hydraulic systems that enable the smooth and efficient transfer of fluids. They are designed to compensate for misalignments and absorb vibrations, thereby preventing damage to the system's components and ensuring its longevity.The working principle behind hydraulic expansion joints is based on their capability of stretching and contracting under pressure and temperature variations. By doing so, they help absorb the shock that occurs when fluids circulate in the system.Different Types of Hydraulic Expansion Joints1. Axial Expansion JointsAxial expansion joints are designed to allow axial (longitudinal) movement within the hydraulic systems. They are ideal for applications requiring the transfer of fluid from one point to another using pipelines.2. Lateral Expansion JointsUnlike axial expansion joints, lateral expansion joints are ideal for transferring fluids in circuits that require lateral (horizontal) movement. They are ideal for applications where pipelines run parallel to each other.3. Angular Expansion JointsSometimes, systems require fluid transfer from a pipeline in one direction to another at an angle. This is where angular expansion joints come in handy. They are designed to absorb angular movements that occur in hydraulic systems.Benefits of Hydraulic Expansion Joints1. Reduction of VibrationsVibrations can be detrimental to hydraulic systems, causing component wear and tear, damage, and even malfunction. Hydraulic expansion joints are designed to reduce these vibrations and absorb any shock that could cause harm to the system's components.2. Compensation for MisalignmentsMisalignments occur when two different pipelines' axes fail to align, causing strain on one of the pipelines or both. This can lead to the premature failure of the system's components. Hydraulic expansion joints are designed to compensate for these misalignments, keeping the system running smoothly and efficiently.3. Longevity of EquipmentHydraulic expansion joints help in mitigating the wear and tear of hydraulic systems, ensuring their longevity. By reducing vibrations, absorbing shock, and compensating for misalignments, the system's components are less likely to fail prematurely.Why Choose Air Hydro Power?At Air Hydro Power, we pride ourselves in providing high-quality hydraulic expansion joints that cater to a wide range of industries. Our team of experts carefully examines each component before assembly to ensure that we only use the best materials available in the market.Our in-house assembly and stocking of standard and hard-to-find components mean that your orders are processed quickly and efficiently. At Air Hydro Power, we are committed to providing exceptional customer support and excellent service.In conclusion, hydraulic expansion joints play a crucial role in the smooth and efficient operation of hydraulic systems. At Air Hydro Power, we have made it our mission to provide high-quality components that meet the demands of various industries. Our industry experience, in-house assembly, and excellent customer service make us the perfect partner for your hydraulic expansion joint needs.

Discover the Benefits of Expansion Bellows Joint for Improved Performance and Flexibility

Title: Advancements in Expansion Bellows Joint Technology Revolutionize Industrial Applications Introduction: Expansion bellows joints, a crucial component in numerous industrial sectors, play a vital role in maintaining the integrity and efficiency of various pipelines and exhaust systems. A recent breakthrough in expansion bellows joint technology by an innovative company has revolutionized the industry, offering enhanced flexibility, durability, and cost-effectiveness. This development is set to transform the way businesses design and operate their systems, leading to improved performance, reduced maintenance costs, and increased productivity.[Paragraph 1]Expansion bellows joints, often referred to as expansion joints or compensators, are critical for allowing thermal expansion, vibration reduction, noise isolation, and movement compensation in piping systems. These joints act as flexible connectors between sections of pipelines, absorbing the movement caused by thermal expansion or contraction, while maintaining the integrity of the overall system. They help avoid stress and strain on pipes, flanges, and equipment, thereby preventing damage and prolonging the lifespan of the entire system.[Paragraph 2]In line with the ever-evolving needs of the industrial sector, the innovative company {} has recently introduced a groundbreaking expansion bellows joint technology that sets new standards for flexibility, durability, and longevity. By integrating cutting-edge materials, advanced manufacturing techniques, and meticulous engineering, this breakthrough technology offers significant advantages over traditional expansion bellows joints in terms of reliability, performance, and cost-effectiveness.[Paragraph 3]The key element in this advanced expansion bellows joint technology is the use of a proprietary composite material, specifically designed to withstand extreme temperatures, aggressive chemical environments, and high-pressure conditions. This material exhibits exceptional resistance to corrosion, abrasion, and fatigue, ensuring long-term durability and reliability. Moreover, the composite material offers superior flexibility, allowing for greater expansion and contraction capabilities without compromising structural integrity.[Paragraph 4]The innovative manufacturing techniques employed in the production of these expansion bellows joints contribute to their outstanding performance. The company utilizes state-of-the-art machinery and automation systems, enabling precise shaping, welding, and quality control throughout the manufacturing process. This ensures the consistency and accuracy of each expansion bellows joint, resulting in products of unparalleled quality and reliability.[Paragraph 5]Beyond the technological advancements, the company also prioritizes customization and flexibility in meeting the diverse needs of different industries. They offer a comprehensive range of expansion bellows joints tailored to specific applications, including power generation plants, chemical processing facilities, oil refineries, HVAC systems, and more. With a team of experienced engineers and experts, the company collaborates closely with clients to develop bespoke solutions that integrate seamlessly into their systems, maximizing efficiency and minimizing downtime.[Paragraph 6]The adoption of this new expansion bellows joint technology promises several benefits for industrial clients. The increased durability and reliability ensure a longer lifespan, reducing maintenance costs and enhancing operational efficiency. The exceptional flexibility allows for greater freedom in system design and installation, reducing the risk of pipe stress, material fatigue, and system failures. Furthermore, the use of the advanced composite material significantly minimizes the risk of leaks, enhancing safety and environmental compliance.[Paragraph 7]Conclusively, the breakthrough expansion bellows joint technology introduced by the innovative company {} has set a new benchmark for the industry. Through the implementation of state-of-the-art materials, advanced manufacturing techniques, and customized solutions, this technology offers businesses in various sectors an opportunity to enhance their system performance, durability, and overall productivity. By investing in this cutting-edge technology, industrial players can stay on the forefront of innovation and achieve sustainable growth in a rapidly evolving market.[Word Count: 550]