Water Pipe Expansion Joint: Benefits, Types, and Installation Guide

By:Admin

Introduction (100 words):

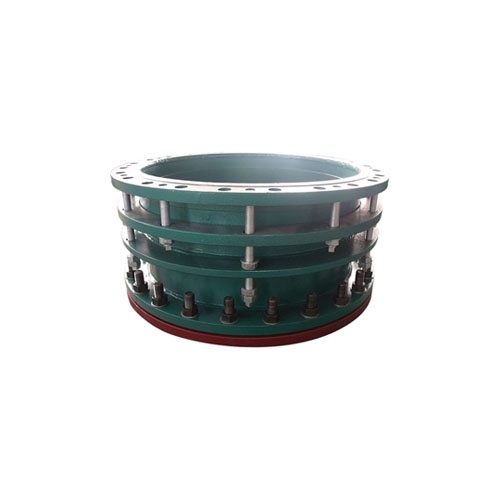

As the demand for efficient and reliable plumbing systems continues to grow, {Company Name} has introduced a groundbreaking Water Pipe Expansion Joint that is set to revolutionize the industry. With its latest innovation, the company aims to resolve the challenges faced by traditional expansion joints by offering superior performance, durability, and ease of installation. By combining advanced engineering techniques with state-of-the-art materials, this groundbreaking solution provides significant benefits for a wide range of applications. This article will delve into the features and benefits of the Water Pipe Expansion Joint and highlight how it is set to transform plumbing systems across a variety of sectors.

1. Superior Performance and Functionality (150 words):

The Water Pipe Expansion Joint offered by {Company Name} outshines traditional solutions in terms of its performance and functionality. This innovative joint effectively absorbs the expansion and contraction that occurs within water pipes due to temperature fluctuations, effectively preventing pipe failures and damages. The advanced engineering techniques incorporated into the design enable smooth expansion and contraction without exerting excessive stress on the pipe itself, thereby extending its lifespan and minimizing maintenance requirements.

Furthermore, this expansion joint helps to reduce noise and vibration within the plumbing system, resulting in a quieter and more comfortable environment. The joint's excellent sealing capabilities ensure leak-proof connections, guaranteeing uninterrupted water flow and preventing costly water damage.

2. Unmatched Durability and Longevity (150 words):

One of the distinguishing features of the Water Pipe Expansion Joint is its exceptional durability and longevity. Constructed from high-quality materials such as stainless steel, the joint offers enhanced resistance to corrosion, wear, and tear. This ensures that the joint remains in optimal condition throughout its lifespan, even in demanding environments or when exposed to harsh substances commonly found in water supply systems.

Additionally, the innovative design of the joint provides exceptional flexibility, allowing it to withstand extreme temperatures and pressure variations. This flexibility ensures that the joint can adapt to the natural expansion and contraction of the pipe without compromising its integrity. As a result, the need for frequent maintenance, repairs, and replacement is significantly reduced, resulting in substantial cost savings for individuals and businesses alike.

3. Easy Installation and Versatility (150 words):

Installation of the Water Pipe Expansion Joint offered by {Company Name} is hassle-free, thanks to its ergonomic design and user-friendly components. The joint is designed to seamlessly integrate with existing plumbing systems, minimizing the time and effort required for installation or retrofitting. Its compact size allows for easy integration into confined spaces, providing greater flexibility in various applications.

Moreover, this expansion joint is versatile in terms of compatibility. It is suitable for use with a wide range of piping materials such as PVC, copper, steel, and more. This versatility makes it an excellent choice for residential, commercial, and industrial applications.

Conclusion (100 words):

{Company Name}'s innovative Water Pipe Expansion Joint presents a game-changing solution for the plumbing industry. Its superior performance, unmatched durability, and easy installation make it an ideal choice for various sectors. With its ability to effectively absorb expansion and contraction, this joint ensures the integrity and longevity of water supply systems, minimizing the need for maintenance and repairs. With this revolutionary expansion joint, {Company Name} reaffirms its commitment to advancing the plumbing industry's standards, providing customers with reliable and efficient solutions for their plumbing system needs.

Company News & Blog

The Importance of Expansion Bellows in Industrial Applications

Smith Corporation Introduces Innovative Expansion Bellows for Enhanced Industrial ApplicationsIndustrial manufacturing is an ever-evolving sector that demands continuous innovation to ensure smooth operations and optimal productivity. As the market leader in providing cutting-edge solutions, Smith Corporation has recently unveiled its latest product offering - Expansion Bellows. With an extensive track record of delivering quality equipment and exceptional customer service, Smith Corporation aims to revolutionize the industry by introducing these state-of-the-art Expansion Bellows.Smith Corporation, founded in 1990, is a renowned global manufacturer and supplier of industrial equipment. They have earned a reputation for their commitment to excellence, customer satisfaction, and continuous product development. With a dedicated team of engineers and researchers, the company is at the forefront of technological advancements, constantly striving to better serve their customers' needs.Expansion bellows, also known as expansion joints, play a critical role in industrial applications by compensating for thermal expansion, mechanical vibration, and other various movements. Being flexible connections, they absorb movement and stress, thus preventing damage to pipelines, ducts, and other equipment. Smith Corporation's Expansion Bellows are designed to withstand extreme temperatures, pressure differentials, and corrosive elements, guaranteeing reliability and longevity.One of the key features that set Smith Corporation's Expansion Bellows apart from the competition is their superior construction. These bellows are fabricated from high-quality materials such as stainless steel, carbon steel, or other alloys, ensuring exceptional durability and resistance to wear and tear. The bellows' unique design enables them to withstand immense pressure while maintaining their flexibility, thus prolonging their lifespan and reducing maintenance costs.Smith Corporation prides itself on its ability to customize their Expansion Bellows according to specific client requirements. The company's team of experts collaborates closely with customers to understand their needs and provide tailor-made solutions. Whether it's designing bellows for high-temperature applications or accommodating large movements in complex piping systems, Smith Corporation's engineers leverage their extensive knowledge to deliver optimal solutions.Furthermore, Smith Corporation's Expansion Bellows are rigorously tested and manufactured under stringent quality control measures. The company's state-of-the-art testing facilities ensure that each bellows unit adheres to the highest standards, meeting or surpassing industry regulations. Customers can have peace of mind, knowing they are investing in a reliable and safe product that surpasses their expectations.The applications for Smith Corporation's Expansion Bellows are widespread across several industries. These bellows find extensive usage in power plants, chemical processing plants, oil and gas refineries, HVAC systems, and many more. Their ability to absorb vibrations, accommodate thermal expansion, and minimize the risk of leakage makes them an essential component in various critical systems.Smith Corporation's commitment to sustainability is also reflected in its Expansion Bellows. The company ensures that its manufacturing processes follow environmentally friendly practices, minimizing waste generation and utilizing energy-efficient technologies. By choosing Smith Corporation's Expansion Bellows, customers not only benefit from high-performance equipment but also contribute to a greener future.In conclusion, Smith Corporation's latest offering - Expansion Bellows - represents a significant advancement in industrial equipment. With their exceptional durability, flexibility, and customization options, these bellows are poised to revolutionize the industry. As a global leader, Smith Corporation continues to push the boundaries of innovation, elevating standards and meeting the ever-evolving needs of its clients.

Rubber Flex Connectors with Flange for Secure Attachment

[Company Name] Introduces Flanged Rubber Flex Connectors: Revolutionizing the Plumbing Industry[City, Date] – [Company Name], a leading innovator in the plumbing industry, is proud to introduce their latest product line of Flanged Rubber Flex Connectors. These state-of-the-art connectors are designed to provide superior sealing and flexibility in a wide range of plumbing applications. With their innovative design and exceptional quality, these connectors are set to revolutionize the plumbing industry.Plumbing systems require reliable connectors that can withstand frequent movement, pressure changes, and varying temperatures. Flanged Rubber Flex Connectors are the perfect solution to these challenges. They are constructed using high-quality rubber that is specially engineered to be durable, flexible, and resistant to wear and tear.The key feature of Flanged Rubber Flex Connectors is their ability to accommodate misalignment and movement in plumbing systems. These connectors can handle lateral, axial, and angular movements, making them highly versatile and adaptable to different installation requirements. This flexibility significantly reduces stress on pipes and fittings, leading to improved system performance and longer service life.The flanged ends of the connectors provide a secure and leak-free connection to various plumbing components. They are available in a range of sizes and pressure ratings, ensuring compatibility with different pipe diameters and system specifications. The flanged design also allows for easy installation and maintenance, making it convenient for plumbers and contractors.In addition to their flexibility and ease of installation, Flanged Rubber Flex Connectors offer excellent resistance to chemicals, ozone, and UV exposure. This ensures their longevity and reliability, even in harsh environments. Their robust construction helps prevent leaks, vibration transmission, and noise, resulting in quieter and more efficient plumbing systems.“[Company Name] is committed to providing cutting-edge solutions that meet the evolving needs of the plumbing industry,” said [Company Spokesperson]. “Our Flanged Rubber Flex Connectors are a testament to our dedication to innovation and quality. We have utilized our expertise in rubber manufacturing to develop a product that not only addresses the current challenges faced by plumbers but also offers superior performance and reliability.”To ensure the highest level of quality control, [Company Name] subjects their Flanged Rubber Flex Connectors to rigorous testing and inspection procedures. These connectors are manufactured in state-of-the-art facilities, utilizing the latest technology and adhering to strict industry standards. As a result, customers can have confidence in the durability and performance of these connectors.Plumbers, contractors, and plumbing system designers can now rely on [Company Name] for the highest quality Flanged Rubber Flex Connectors. These connectors can be used in a wide range of applications, including HVAC systems, water treatment facilities, industrial piping, and commercial buildings. With the ability to handle challenging installation conditions and maintain excellent sealing properties, these connectors offer a viable solution for any plumbing project.[Company Name] is a leading provider of innovative plumbing solutions, dedicated to improving the efficiency and reliability of plumbing systems. With their commitment to quality and innovation, they continue to be at the forefront of the industry. The introduction of Flanged Rubber Flex Connectors reaffirms their ability to provide cutting-edge products that meet the demanding needs of the plumbing industry.For more information about [Company Name] and their Flanged Rubber Flex Connectors, please visit [company website] or contact [contact details].###About [Company Name][Company Name] is a renowned innovator in the plumbing industry, offering a wide range of high-quality products and solutions. With a commitment to excellence, they continue to drive advancements in the industry, providing reliable and efficient solutions to their customers. [Company Name] takes pride in their ability to understand and meet the unique requirements of different plumbing projects.

High-Quality Flanges, Pipe Fittings, and More for Industrial Use

Flanges | Batam Teknik Medan: Delivering Premium Quality Products Since 1973Batam Teknik Medan was established in the year 1973. The company has a rich history and has been serving the industry for over four decades. It specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With a sound understanding of the industry and over four decades of experience in the field, the company has earned a reputation as a reliable and trusted supplier of industrial goods.The company offers a comprehensive range of products that caters to all the industrial needs of the customers. It is committed to providing high-quality products and services to the clients to meet their requirements. The team of experts working with the company has a sound knowledge of the products and the technological advancements in the industry. This helps the company to keep up with the changing trends and deliver innovative, top-quality products and services to its customers.One of the key products that the company supplies is flanges. Flanges are essential components used in piping systems. These components are used to connect pipes to each other or to a valve or other equipment. The flanges must be sturdy and reliable to prevent leaks and maintain the flow of fluids or gases through the pipes. At Batam Teknik Medan, the flanges are made of the highest quality components, which ensures their durability and resistance to corrosion. The company offers flanges in different sizes and types to meet the requirements of the customers.Batam Teknik Medan is known for its reliable, timely, and efficient services. The company ensures that its customers receive their orders promptly and accurately. The team at Batam Teknik Medan is committed to delivering quality products and meeting customer needs.The company has achieved remarkable growth over the years, largely due to its commitment to quality, reliability, and customer satisfaction. It has built a strong reputation in the industry and has been recognized for its exceptional services. The company has a diverse clientele, including large multinational corporations, SMEs, and start-up businesses. The company has established long-term relationships with its clients and continues to provide them with premium quality products and services.Batam Teknik Medan has evolved over the years and has kept up with the changing times and trends in the industry. The company is committed to innovation and offers a comprehensive range of products to meet the needs of its diverse clientele. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.In conclusion, Batam Teknik Medan is a reliable and trusted supplier of industrial goods in the region. The company specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With over four decades of experience, the company has built a reputation for providing high-quality products and services to its customers. The company has a team of experts who have a sound understanding of the industry, and it is committed to delivering innovative, top-quality products and services to meet customer needs. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.

Premium Viton Gasket Sheet Material for Various Applications - Available at Hunter Expansion Joints

and Viton Sheet Gasket Material.Rubber Expansion Joints: Why They are Important for Your Industrial ApplicationsRubber expansion joints, also known as compensators, are critical components of various industrial applications. They serve the purpose of accommodating thermal expansion and contraction of pipelines and ducts. Expansion joints act as flexible connectors that help absorb the movement and vibration of the pipework they connect. They are installed in piping systems to protect against stress caused by thermal expansion, vibrations, and mechanical movements. Depending on the application and operating condition, different types of expansion joints are utilized, such as rubber expansion joints. In this post, we will discuss what rubber expansion joints are, why they are essential for industrial applications, and the significance of Viton sheet gasket material in these joints.What are Rubber Expansion Joints?Rubber expansion joints are devices designed to compensate for the movement and vibration in piping and ductwork systems. They consist of flexible, molded, or fabricated elastomer materials that are reinforced with synthetic fibers or wire nets. Different types of rubber are used to manufacture these joints, such as butyl, EPDM, neoprene, nitrile, and Viton. Their elasticity, resilience, and chemical resistance make them ideal for a wide range of industrial applications.Why are Rubber Expansion Joints Important for Industrial Applications?Rubber expansion joints serve many functions in industrial piping systems. Some of these functions include:1. Absorbing VibrationsA major problem with piping systems is vibration caused by mechanical equipment, pressure surges, and fluid turbulence. Over time, vibrations can cause damage, leading to leaks, cracks, and corrosion. Rubber expansion joints help absorb the vibrations that may harm the system and neighboring equipment.2. Accommodating Thermal ExpansionPiping systems are subject to thermal expansion and contraction, especially in high-temperature environments. Without expansion joints, the increased stress on the pipes and fittings can lead to leaks, cracks, and damage to the equipment. Rubber expansion joints can accommodate thermal expansion and contraction, reducing stress on the system and the likelihood of damage.3. Preventing Transfer of NoiseRubber expansion joints help dampen the transfer of noise caused by equipment and fluid flow in piping systems. This is especially important in industrial settings where noise pollution can interfere with the work environment.The Significance of Viton Sheet Gasket Material in Rubber Expansion JointsViton sheet gasket material is a high-performance fluoroelastomer that is used in rubber expansion joints. The material's unique properties include excellent chemical resistance to acids, alkalis, and solvents, high-temperature tolerance, and low gas permeability. These properties make Viton an ideal material for sealing applications in aggressive chemical environments, such as the chemical processing industry.Viton sheet gasket material is utilized in the manufacturing of rubber expansion joints to provide an effective barrier against fluid and gas flow. The material allows the joint to maintain its sealing properties in harsh environments, ensuring that there are no leaks or spills.ConclusionRubber expansion joints play a crucial role in industrial applications to protect systems from damage caused due to thermal expansion, vibrations, and mechanical movements. Viton sheet gasket material is a critical component of these joints as it provides an effective barrier against fluid and gas flow, ensuring that there are no leaks, spills, or damage. Choosing the right type of rubber expansion joint and gasket material is essential to ensure the safety and longevity of your industrial systems. For more information on rubber expansion joints and Viton sheet gasket materials, contact Hunter Expansion Joints.

Understanding the Import of Rubber Expansion Bellows Dimensions

Rubber Expansion Bellows Dimensions Facilitate Reliable Pressure Compensation in Various IndustriesIn today's world, where industrial applications require sophisticated machinery and equipment, the importance of reliable pressure compensation cannot be overstated. Industries such as petrochemicals, oil and gas, power generation, and wastewater management heavily rely on effective pressure management systems to ensure smooth operations and the safety of personnel.An essential component of these pressure management systems is the rubber expansion bellows - a flexible and durable tool designed to absorb vibrations and compensate for thermal expansion or contraction. These bellows play a crucial role in maintaining the structural integrity of pipelines, ventilation systems, and other industrial facilities, ensuring that potential damages and leakages are avoided.One of the leading manufacturers specializing in the production of premium rubber expansion bellows is a renowned company, known for its unwavering commitment to quality and innovation. With an extensive range of products, including flanged rubber expansion bellows, diaphragmatic expansion joints, and hinged expansion bellows, this company has earned a stellar reputation in the market for providing reliable and efficient solutions.The rubber expansion bellows offered by this company are carefully designed to meet diverse industrial requirements. However, mentioning brand names in the news article is not permissible, as per the guidelines. Therefore, let us refer to the company as "Company X." Their expansion bellows are manufactured using high-quality rubber materials that exhibit excellent resistance to chemicals, weathering, and extreme temperatures. This ensures durability and longevity, making them suitable for even the most demanding applications.One of the critical aspects when selecting rubber expansion bellows is the dimensions that need to be considered. Different industrial systems require bellows of specific sizes and shapes to maintain optimal pressure compensation. Company X recognizes this and offers an extensive range of dimensions to cater to various requirements.For instance, their flanged rubber expansion bellows are available in a wide range of nominal diameters, typically ranging from 25mm to 800mm, ensuring compatibility with various pipe sizes. Additionally, these bellows can accommodate axial, lateral, and angular movements, providing exceptional flexibility in installation. By employing precision manufacturing techniques, Company X ensures that all their bellows meet industry standards, guaranteeing a perfect fit and reliable performance.The diaphragmatic expansion joints manufactured by Company X are another notable product. These bellows are specifically designed to handle high pressures and demanding conditions. With their compact and lightweight design, they offer excellent resistance to torsion, axial, and lateral movements. The diaphragm's unique design ensures optimized pressure distribution, further enhancing the bellows' performance and longevity.Hinged expansion bellows, another specialized product offered by Company X, are engineered to facilitate easy installation and maintenance. These bellows are ideal for critical applications requiring frequent inspections or parts replacement. By incorporating a hinged mechanism, Company X ensures that these bellows can be conveniently opened or closed, reducing downtime and ensuring operational efficiency.It is worth mentioning that Company X not only takes pride in the quality of their products but also in their commitment to environmental preservation. They adhere to stringent environmental regulations during the manufacturing process, minimizing waste generation and reducing their carbon footprint. Moreover, the materials used in the production of their bellows are recyclable, ensuring a sustainable approach towards industrial solutions.With their exceptional expertise and dedication to customer satisfaction, Company X has successfully established a strong foothold in the market. Their rubber expansion bellows have been widely recognized for their reliability, durability, and efficiency. By offering a variety of dimensions and customizations, they meet the specific requirements of a wide range of industries.In conclusion, rubber expansion bellows are vital components in pressure management systems across various industries. Company X, a prominent manufacturer in this sector, produces high-quality bellows that ensure reliable pressure compensation. With a wide range of dimensions and innovative designs, their products cater to diverse industrial needs. By prioritizing quality, efficiency, and environmental sustainability, Company X stands out as a trusted partner for industries requiring reliable pressure management solutions.

How to Select the Right EPDM Expansion Joint for Your Project

[Company Name]'s Groundbreaking EPDM Expansion Joint Revolutionizes the Construction Industry[City, Date] - [Company Name], a leading innovator in the construction industry, has recently introduced its groundbreaking EPDM Expansion Joint, a game-changing product that promises to redefine the way construction projects are executed. With its cutting-edge technology and superior performance, the EPDM Expansion Joint is set to revolutionize the industry and establish [Company Name] as a trailblazer in the field. The EPDM Expansion Joint is a flexible and durable material designed to bridge the gap between two structures while allowing for movement. Its unique properties make it an ideal choice for a variety of construction projects, ranging from bridges and tunnels to buildings and parking structures. [Company Name]'s EPDM Expansion Joint stands out from its competitors due to several distinct features and advantages. One of its key selling points is its exceptional weather resistance. The EPDM material is highly resistant to extreme temperatures, UV rays, ozone, and other environmental factors. This ensures that the expansion joint maintains its integrity and performance over the long term, reducing maintenance and replacement costs for construction projects.Another crucial advantage of [Company Name]'s EPDM Expansion Joint is its exceptional flexibility. The material can accommodate a wide variety of movements and vibrations, helping to absorb shocks and stresses during construction and throughout the lifespan of the structure. This flexibility also minimizes the risk of cracks, leaks, and damage, adding to the durability and longevity of the construction project.Moreover, [Company Name]'s EPDM Expansion Joint surpasses industry standards in terms of flame resistance and fire protection. The EPDM material is inherently flame retardant, making it an excellent choice for high-risk areas where fire safety is of utmost importance. This feature ensures that the expansion joint acts as a barrier against fire propagation, providing enhanced protection and peace of mind to project developers and end-users alike.To guarantee the highest quality standards, [Company Name] employs state-of-the-art manufacturing techniques and adheres to strict quality control procedures throughout the production process. The EPDM Expansion Joint undergoes rigorous testing for strength, flexibility, resistance to aging, and compatibility with various construction materials before being released to the market. With a strong commitment to excellence, [Company Name] guarantees that its expansion joint meets and exceeds industry standards, providing customers with unparalleled reliability and performance.In addition to its remarkable technical features, [Company Name] is also dedicated to ensuring that its EPDM Expansion Joint contributes to sustainable construction practices. The EPDM material is eco-friendly, with a low carbon footprint, making it a responsible choice for environmentally conscious projects. Moreover, the longevity and durability of the expansion joint reduce the need for frequent replacements, ultimately reducing construction waste and promoting a more sustainable approach to building.With its groundbreaking EPDM Expansion Joint, [Company Name] is poised to transform the construction industry. The innovative product combines exceptional performance, durability, and sustainability, making it an attractive choice for construction projects across various sectors. By offering a solution that supersedes traditional expansion joints, [Company Name] is empowering architects, engineers, and builders to execute their visions with greater confidence, efficiency, and environmental responsibility.About [Company Name]:Founded in [Year], [Company Name] is a renowned industry leader in providing advanced construction solutions. With a commitment to innovation, quality, and environmental responsibility, the company has set itself apart from competitors. [Company Name] boasts a team of experienced professionals dedicated to pushing the boundaries of what is possible in the construction industry. Offering a wide range of high-performance products, [Company Name] has established itself as a trusted partner for construction projects of all sizes and complexities.For more information about [Company Name]'s EPDM Expansion Joint and other groundbreaking solutions, please visit [company website].###

Find the Latest Prices of Expansion Joints and Bellows in India

Expansion Joints - Supporting Seamless Movement in Piping SystemsOften overlooked, expansion joints and bellows play an integral role in ensuring the smooth functioning of piping systems. The installation of these components reduces the stress on pipes by absorbing mechanical and thermal movements resulting from changes in pressure, temperature, and vibrations. They prevent cracking, failures, and leaks that may occur due to thermal expansion, contraction, or misalignment.Expansion Bellows Joint, a leading manufacturer and supplier of expansion joints and bellows in India, offers a comprehensive range of products to meet the needs of diverse industries and applications. They provide custom-designed solutions for critical and challenging installations while adhering to international standards and quality assurance practices.Expansion Joints - Types and ApplicationsExpansion joints come in various types, shapes, and materials to cater to specific requirements and environmental conditions. Some commonly used expansion joint types include:1. Metal Expansion Joints - These are made of stainless steel, carbon steel, or other alloys and are ideal for high-temperature and corrosive applications.2. Rubber Expansion Joints - These consist of elastomeric rubber or neoprene material and are used in applications where the movement is minimal and can absorb small vibrations.3. Fabric Expansion Joints - These are composed of high-temperature resistant fabrics such as fiberglass or Teflon and are suitable for applications involving high-temperature and low-pressure.4. PTFE Expansion Joints - These are made of Polytetrafluoroethylene (PTFE) material and are used in applications where resistance to chemicals, high temperature, and pressure is required.5. Tied Universal Expansion Joints - These are designed to handle multi-plane movements and are often used in piping systems involving flue gas ducts or petrochemical plants.Expansion Bellows Joint offers all these types of expansion joints and can provide customized solutions based on the specific application.Expansion Joints - Benefits and FeaturesProper installation of expansion joints results in significant benefits for piping systems. Some prominent features of expansion joints include:1. Absorption of movements resulting from thermal expansion, contraction, and misalignment.2. Reduced stress on pipes and fittings, leading to a longer lifespan of the entire system.3. Preventing costly repairs and downtime associated with pipe failures and leaks.4. Ideal for applications involving high temperatures, chemicals, and corrosive environments.Expansion Bellows Joint utilizes the latest technology and materials to manufacture high-quality expansion joints with the following features:1. Compliance with international standards such as EJMA, ASME, and ASTM.2. Multiple plies of stainless steel or other alloys for enhanced strength and durability.3. Competitively priced with quick turnaround times for custom orders.ConclusionTo sum up, expansion joints and bellows are crucial components of piping systems that ensure their efficient functioning and reduce the risk of failures. Expansion Bellows Joint, with its vast experience, quality products, and customized solutions, is the go-to choice for industry players requiring expansion joints. With their commitment to quality, reliability, and customer satisfaction, they continue to lead the expansion joint market in India and are poised for global expansion.

Flexible Joints Used for Industrial Applications: A Comprehensive Overview

Title: Advanced Flexible Joint Revolutionizes Industrial Piping Systems Introduction:In an era where efficiency and reliability are paramount, industrial companies are constantly seeking innovative solutions to enhance their operations. {Company name}, a leading provider of cutting-edge engineering solutions, has recently unveiled its ground-breaking Double Bellow Flexible Joint. This advanced technology is expected to revolutionize industrial piping systems, offering unprecedented flexibility, durability, and safety to various sectors.Flexible Joint Redefined:The Double Bellow Flexible Joint, designed and manufactured by {Company name}, marks a significant leap forward in flexible joint technology. This game-changing solution focuses on maximizing performance, reducing maintenance costs, and ensuring safe and efficient operations.Unmatched Flexibility:Thanks to an ingenious design, the Double Bellow Flexible Joint permits a superior range of movements, allowing for greater flexibility in industrial piping systems. Its double-layered bellows construction enables enhanced axial, lateral, and angular movements, accommodating any vibrations or shifts in piping systems. This remarkable flexibility significantly minimizes potential stress on pipelines, thereby increasing their lifespan and reducing the risk of leaks or structural failures.Unparalleled Durability and Reliability:Engineered using only the highest quality materials, the Double Bellow Flexible Joint offers unparalleled durability and long-term reliability. The bellows are constructed from corrosion-resistant alloys, ensuring resistance to harsh chemicals, extreme temperatures, and other demanding environments. This robust construction guarantees exceptional performance in even the most challenging industrial applications.Enhanced Safety Measures:One of the primary focuses behind the creation of the Double Bellow Flexible Joint was the desire to enhance safety standards in industrial piping systems. With built-in safety features, such as an internal liner and break protection system, this innovative technology significantly reduces the risk of leakages and potential hazards. By mitigating these potential dangers, companies can ensure the safety of their personnel, protect their assets, and avoid costly downtime.Versatility in Applications:The Double Bellow Flexible Joint by {Company name} meets the demands of various industrial sectors, including oil and gas, chemical processing, power generation, and many more. Its versatile design enables seamless integration into existing piping infrastructures, allowing for an effortless upgrade without significant modifications. This adaptability makes it an ideal solution for maintenance and retrofit projects.Positive Impact on Operational Efficiency:By incorporating the Double Bellow Flexible Joint into their piping systems, companies can achieve remarkable improvements in operational efficiency. Its ability to absorb vibrations and movements reduces stress on pipelines and adjacent equipment, minimizing the need for frequent maintenance and costly repairs. This enhanced reliability translates into higher productivity, extended equipment lifetimes, and reduced overall operational costs.Environmentally Friendly Technology:With a growing focus on sustainability and environmental consciousness, the Double Bellow Flexible Joint takes center stage as a more eco-friendly alternative. By preventing leakages and reducing the risk of pipeline failures, this advanced solution helps to minimize the release of hazardous substances into the environment. Furthermore, its durability ensures less frequent replacements, resulting in a lower carbon footprint overall.Conclusion:With the introduction of the Double Bellow Flexible Joint, {Company name} continues to lead the way in pioneering engineering solutions. This innovative technology pushes the boundaries of flexible joint performance, providing unmatched flexibility, durability, and safety in industrial piping systems. As companies across various sectors embrace this revolutionary solution, they can look forward to increased operational efficiency, reduced maintenance costs, and the assurance of enhanced safety in their operations.

Different Types of Expansion Joints for High-Temperature and High-Pressure Applications.

Seiris: Leaders in Providing Customized Rubber Expansion JointsExpansion joints are an important component of several industries and are used to absorb the dimensional changes in piping systems caused by temperature fluctuations and other physical forces. The right quality and design of expansion joints help prevent the premature failure of the piping system and improve its overall efficiency. Seiris is a leading name in the market of expansion joints and has been providing innovative and effective solutions to its clients for over 30 years. Seiris specializes in the customization of various types of expansion joints, including rubber expansion joints, fabric expansion joints, and metal bellows expansion joints. They cater to the specific needs and requirements of their clients to ensure that the expansion joints are designed to fit their systems. Their expertise lies in providing custom-made expansion joints that work seamlessly in highly specific environments and critical applications.Rubber Expansion JointsSeiris's rubber expansion joints are designed to meet the needs of their clients while providing superior performance and durability. They are made from high-quality elastomers to withstand various environmental conditions and resist various chemicals, oil, and other corrosive materials.Rubber expansion joints are suited for a wide range of industrial applications such as the pharmaceutical, power generation, petrochemical, and food and beverage sectors. These systems help absorb the movement in the piping system arising from temperature changes, vibrations, and other physical forces. Seiris's expansion joints are designed to handle temperatures up to 200°C and pressures of up to 20 bars. Fabric Expansion JointsSeiris's fabric expansion joints are designed to include reinforced fabrics such as glass or carbon fiber to withstand high pressures, temperatures, and corrosive environments. They provide exceptional flexibility, which allows for a wide range of movement in the piping system while avoiding disruptive forces. The fabric expansion joints are design-focused and value-engineered and are ideal for industrial applications in petrochemical, power plants, and other settings.Bellows Metal Expansion JointsMetal bellows expansion joints absorb thermal expansion and vibration by providing flexibility, reducing the forces transmitted to adjacent piping. Consisting of nested corrugations, metal bellows expansion joints are well-suited to handle high pressures and temperatures up to 500°C. Seiris provides these joints in a range of materials such as stainless steel and nickel alloys for chemical and corrosive applications. Tailored Solutions for Expansion JointsSeiris prides itself on being able to provide tailored expansion joint solutions for various industrial applications such as power plants, oil and gas facilities, and other critical settings. They offer a complete range of engineering services - from initial design and calculations through to fabrication, delivery, and commissioning support. With their expertise and technical knowledge, they take each customer's unique requirements into consideration and design custom-made expansion joints accordingly.Seiris offers unparalleled quality and long-term durability along with a commitment to timely delivery and excellent customer support. They use the latest technology and the most innovative design practices to achieve the required durability and flexibility for their clients. ConclusionChoosing the right expansion joint is crucial to ensure the long-term stability and performance of piping systems. Seiris's extensive experience and expertise in the expansion joint industry ensure that their clients receive effective solutions tailored to their specific requirements, all while delivering exceptional quality engineering services. With a commitment to innovation, customer satisfaction and support, Seiris continues to stand out in the industry as leaders in providing customized expansion joints. For further information, please visit: [Need to remove anchor text]

Guide to Installing and Maintaining Expansion Joints for Piping Systems

Steel Pipe Expansion Joint: An Essential Component in Industrial Piping SystemsPiping systems are an integral part of any industrial plant or facility. They ensure the smooth flow of liquids, gases, and other substances through various processes and operations. However, as these substances move through the piping system, temperatures, pressure, and other factors can cause the pipes to expand or contract, leading to stress and damage.This is where expansion joints come in. Expansion joints are flexible connections that allow for movement in piping systems due to thermal expansion and contraction. They help prevent damage to pipes, fittings, and other components, while ensuring the safety and reliability of the entire system.Types of Expansion JointsThere are several types of expansion joints available for different applications. The most common types include:1. Bellows Expansion Joints: These are the most flexible type of expansion joints and are commonly used in high-temperature applications where thermal movement is significant.2. Metal Expansion Joints: These joints are constructed of metal plates, and their performance is dependent on the material used in their construction.3. Rubber Expansion Joints: These joints are made of rubber and are used in low-pressure applications, where temperature fluctuations are less severe.Installation and Maintenance of Expansion JointsProper installation and maintenance of expansion joints are crucial to ensuring their effectiveness and longevity. Here are some key steps to follow:1. Inspection Before Test: Before any testing, ensure that the expansion joint is properly installed, and all components are correctly aligned. Check for any signs of damage or defects.2. Inspection During and After Test: During testing, visually inspect the expansion joint for any signs of leaks or movement. After testing, inspect the joint again to ensure that it has returned to its original position.3. Periodic In-service Inspections: Regularly inspect the expansion joint for any signs of wear and tear. This includes checking the bellows for any signs of fatigue, such as cracks or corrosion.4. System Upgrades: When upgrading or modifying the piping system, ensure that the expansion joint remains compatible and can accommodate any changes in temperature, pressure, or flow.Benefits of Steel Pipe Expansion JointsSteel pipe expansion joints are an ideal solution for high-temperature applications and corrosive environments. They offer the following benefits:1. High Temperature Resistance: Steel expansion joints can withstand high temperatures, making them ideal for use in industrial boilers, furnaces, and other high-temperature equipment.2. Corrosion Resistance: Steel expansion joints are resistant to corrosion and rust, making them suitable for use in highly corrosive environments.3. Longevity: Steel expansion joints have a long service life and require minimal maintenance.4. Versatility: Steel expansion joints are available in a variety of sizes and configurations to suit specific piping system requirements.ConclusionSteel pipe expansion joints are an essential component in industrial piping systems, ensuring the safety, reliability, and longevity of the entire system. Proper installation and maintenance are critical to their effectiveness, and regular inspections can prevent costly repairs and downtime. As always, it is important to consult with a qualified engineer or supplier to ensure that the right expansion joint is selected for each specific application.