Top 5 Benefits of Hypalon Joints You Need to Know

By:Admin

FOR IMMEDIATE RELEASE

Introducing the New Joint Hypalon: Revolutionary Technology for Ultimate Durability

We are excited to announce the launch of our latest product, Joint Hypalon, a cutting-edge material that will revolutionize the industry with its unparalleled durability and versatility. Developed by our team of experts at [Company Name], Joint Hypalon is a game-changing technology that is set to redefine the standard for performance and reliability in a wide range of applications.

First developed in [year], [Company Name] has been a leader in the development and manufacturing of advanced materials for various industries. With a commitment to innovation and excellence, we have continually pushed the boundaries of what is possible in material science. The launch of Joint Hypalon represents the culmination of years of research and development, and we are proud to introduce this groundbreaking new material to the market.

What sets Joint Hypalon apart is its exceptional strength, resilience, and resistance to extreme conditions. Whether it's exposed to harsh weather, UV radiation, chemicals, or abrasion, Joint Hypalon maintains its integrity and performance, making it the ideal choice for demanding applications. Its unique composition and structural design ensure that it can withstand the toughest environmental conditions, making it a reliable and long-lasting solution for a wide range of industries.

One of the key benefits of Joint Hypalon is its unparalleled durability. Unlike traditional materials, which can degrade over time and require frequent maintenance and replacement, Joint Hypalon offers unmatched longevity and performance. This not only reduces the overall cost of ownership but also minimizes downtime and disruptions, making it a cost-effective solution for businesses and industries.

Furthermore, Joint Hypalon is incredibly versatile and can be customized to meet the specific requirements of different applications. Whether it's used in marine, automotive, aerospace, or industrial settings, Joint Hypalon can be tailored to deliver optimal performance and functionality. Its flexibility and adaptability make it a truly universal material that can address a wide range of needs and challenges across diverse industries.

In addition to its exceptional durability and versatility, Joint Hypalon is also environmentally friendly. As a responsible and forward-thinking company, we are committed to developing sustainable solutions that minimize our environmental footprint. Joint Hypalon is manufactured using eco-friendly processes and materials, and its long lifespan means that it contributes to reducing waste and resource consumption.

We are confident that Joint Hypalon will set a new standard for performance and reliability, and we are excited about the possibilities that it offers for our customers and partners. With its advanced technology, unmatched durability, and environmental benefits, Joint Hypalon is a powerful and game-changing material that will revolutionize the way industries approach material selection and application.

At [Company Name], we are dedicated to pushing the boundaries of innovation and delivering superior solutions that meet the evolving needs of our customers. Joint Hypalon is a testament to our commitment to excellence, and we are proud to bring this revolutionary material to the market.

For more information about Joint Hypalon and its applications, please visit our website or contact us directly. We look forward to the opportunity to discuss how Joint Hypalon can benefit your business and industry.

About [Company Name]:

[Company Name] is a leading developer and manufacturer of advanced materials for a wide range of industries. With a focus on innovation, quality, and sustainability, we are committed to delivering superior solutions that exceed the expectations of our customers. Through our dedication to research and development, we continue to set new standards for performance and reliability, and we are proud to introduce groundbreaking materials like Joint Hypalon to the market.

Contact:

[Company Name]

Address: [Company Address]

Phone: [Company Phone Number]

Email: [Company Email]

Website: [Company Website]

Company News & Blog

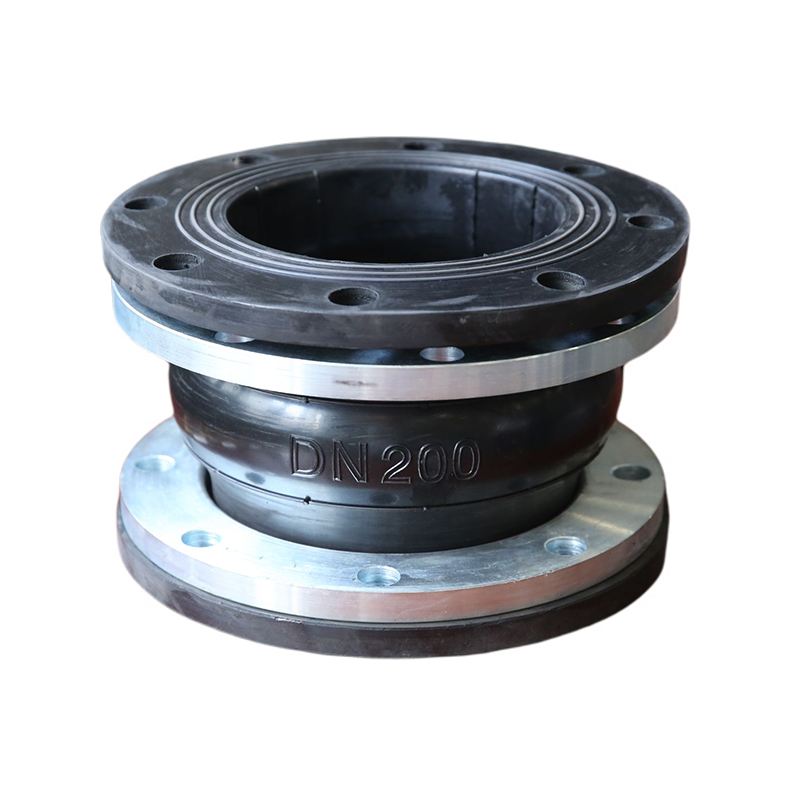

Durable and Efficient Rubber Coupling Joint for Industrial Use

{Company Name}, a leading manufacturer in the industrial equipment sector, has recently announced the release of a new and improved Rubber Coupling Joint. This innovative product is designed to provide efficient and reliable performance in a wide range of industrial applications, making it a valuable addition to the company's extensive product line.The Rubber Coupling Joint is a critical component in many industrial systems, particularly those involving machinery and equipment that require the transmission of power and torque. This versatile product is widely used in the automotive, manufacturing, and construction industries, among others, and plays a crucial role in ensuring the smooth and efficient operation of various types of machinery.One of the key features of the Rubber Coupling Joint is its ability to effectively dampen vibration and reduce noise, which is essential for maintaining the overall performance and longevity of industrial equipment. This is particularly important in high-speed and high-torque applications, where excessive vibration and noise can lead to premature equipment failure and costly downtime.In addition to its exceptional vibration and noise-dampening capabilities, the Rubber Coupling Joint also offers superior flexibility and misalignment compensation. This allows it to accommodate for any minor misalignments between connected shafts, thereby reducing the risk of component damage and ensuring smooth operation.Furthermore, the Rubber Coupling Joint is designed to withstand harsh environmental conditions, making it ideal for use in demanding industrial settings. Its robust construction and durable materials ensure that it can withstand exposure to moisture, chemicals, and extreme temperatures, without compromising its performance or reliability.{Company Name} has a long-standing reputation for producing high-quality industrial equipment, and the release of the new Rubber Coupling Joint further reinforces its commitment to providing innovative solutions for the industrial sector. With a focus on precision engineering and advanced technology, the company continues to push the boundaries of industrial equipment design and performance.The development and release of the Rubber Coupling Joint is a testament to {Company Name}'s dedication to meeting the evolving needs of its customers. By continuously investing in research and development, the company is able to deliver cutting-edge products that are not only reliable and efficient but also environmentally friendly, contributing to sustainable industrial practices.In addition to the Rubber Coupling Joint, {Company Name} offers a comprehensive range of industrial equipment, including gearboxes, couplings, and other power transmission components. With a commitment to quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses across a wide range of industries.As the global industrial landscape continues to evolve, {Company Name} remains at the forefront of innovation, ensuring that its products meet the highest standards of performance, efficiency, and sustainability. The release of the new Rubber Coupling Joint is just one example of how {Company Name} continues to drive progress in the industrial equipment sector, providing solutions that empower businesses to thrive in a competitive market.In conclusion, the release of the new Rubber Coupling Joint is a significant milestone for {Company Name}, and a testament to its ongoing commitment to excellence in industrial equipment manufacturing. With its advanced features and proven performance, this innovative product is poised to make a positive impact on a wide range of industrial applications, further solidifying {Company Name}'s position as a leader in the industry.

Thermal Expansion Joints: Understanding Their Importance and Applications

Thermal Expansion Bellows Offer Innovative Solutions in Industrial ApplicationsThermal expansion is an inherent property of many materials, and its effects can be seen in various industries. To counteract the potential damages caused by thermal expansion, companies often rely on innovative technologies such as thermal expansion bellows. These sophisticated devices help mitigate the adverse effects of expansion and contraction, ensuring the longevity and efficiency of industrial systems. One notable manufacturer in this industry is an esteemed company that has been revolutionizing the sector with its cutting-edge thermal expansion bellows solutions.Founded in {insert year}, this company has been a pioneer in the field of thermal expansion bellows. With a commitment to quality, innovation, and customer satisfaction, the company has garnered an excellent reputation in various industries. Their comprehensive range of thermal expansion bellows caters to the unique requirements of different applications, providing effective and reliable solutions to address the challenges posed by thermal expansion.The company's thermal expansion bellows are known for their exceptional performance and durability. Engineered using state-of-the-art technology and high-quality materials, these bellows can withstand extreme temperatures, pressure differentials, and corrosive environments. This ensures their longevity and reliability in even the most demanding working conditions. By incorporating advanced design and manufacturing techniques, the company ensures that their bellows offer precise movement, minimal friction, and accurate compensation for thermal expansion, allowing systems to maintain their optimal performance.The applications of thermal expansion bellows are vast and varied. They find extensive usage in industries such as power generation, oil and gas, petrochemicals, aerospace, automotive, and many more. In power generation, for instance, thermal expansion bellows are employed in turbines, heat exchangers, and piping systems to compensate for the expansion and contraction of materials due to temperature fluctuations. By accommodating these movements, the bellows prevent excessive stress and fatigue on system components, minimizing the risk of damage and enhancing the overall efficiency and lifespan of the equipment.Moreover, in the oil and gas industry, thermal expansion bellows play a vital role in piping systems and refineries. With the ability to resist high pressures, extreme temperatures, and corrosive mediums, the bellows ensure the reliability and safety of critical infrastructure. By accommodating thermal expansion and preventing leakage or failure, they contribute to the seamless operation of essential processes, preventing costly downtime and hazardous situations.One key aspect that sets this company apart from its competitors is its ability to provide tailor-made solutions. Understanding that each industry and application has unique demands, the company offers a comprehensive range of customizable bellows. Their team of experienced engineers works closely with clients to understand their specific requirements and design bellows that precisely cater to their needs. From material selection to shape and size, the company ensures that every aspect of the thermal expansion bellows aligns with the customer's specifications, thus maximizing efficiency and performance.Apart from their product excellence, the company prioritizes customer satisfaction by providing exceptional pre and post-sale services. Their dedicated support team assists clients throughout the entire process, from initial consultation to installation and maintenance. With a strong emphasis on communication and collaboration, the company ensures that customers receive prompt responses and tailored assistance for their unique challenges.In a rapidly evolving world, thermal expansion bellows have become indispensable in many industries. With the commitment to innovation, quality, and customer-centric solutions, this company continues to lead the way in providing state-of-the-art thermal expansion bellows. By addressing the challenges posed by thermal expansion, their bellows contribute to the seamless operation, longevity, and efficiency of industrial systems, enabling companies to thrive in competitive markets.

High-Quality Flanges, Pipe Fittings, and More for Industrial Use

Flanges | Batam Teknik Medan: Delivering Premium Quality Products Since 1973Batam Teknik Medan was established in the year 1973. The company has a rich history and has been serving the industry for over four decades. It specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With a sound understanding of the industry and over four decades of experience in the field, the company has earned a reputation as a reliable and trusted supplier of industrial goods.The company offers a comprehensive range of products that caters to all the industrial needs of the customers. It is committed to providing high-quality products and services to the clients to meet their requirements. The team of experts working with the company has a sound knowledge of the products and the technological advancements in the industry. This helps the company to keep up with the changing trends and deliver innovative, top-quality products and services to its customers.One of the key products that the company supplies is flanges. Flanges are essential components used in piping systems. These components are used to connect pipes to each other or to a valve or other equipment. The flanges must be sturdy and reliable to prevent leaks and maintain the flow of fluids or gases through the pipes. At Batam Teknik Medan, the flanges are made of the highest quality components, which ensures their durability and resistance to corrosion. The company offers flanges in different sizes and types to meet the requirements of the customers.Batam Teknik Medan is known for its reliable, timely, and efficient services. The company ensures that its customers receive their orders promptly and accurately. The team at Batam Teknik Medan is committed to delivering quality products and meeting customer needs.The company has achieved remarkable growth over the years, largely due to its commitment to quality, reliability, and customer satisfaction. It has built a strong reputation in the industry and has been recognized for its exceptional services. The company has a diverse clientele, including large multinational corporations, SMEs, and start-up businesses. The company has established long-term relationships with its clients and continues to provide them with premium quality products and services.Batam Teknik Medan has evolved over the years and has kept up with the changing times and trends in the industry. The company is committed to innovation and offers a comprehensive range of products to meet the needs of its diverse clientele. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.In conclusion, Batam Teknik Medan is a reliable and trusted supplier of industrial goods in the region. The company specializes in providing stainless & carbon pipes, pipe fittings, flanges, steam & pressure gauges, valves, water meters, manometers, packings, reflec glasses, Toxen flexible rubber joints, Showa Giken pearl rotary joints, etc. With over four decades of experience, the company has built a reputation for providing high-quality products and services to its customers. The company has a team of experts who have a sound understanding of the industry, and it is committed to delivering innovative, top-quality products and services to meet customer needs. With a strong focus on quality, reliability, and customer satisfaction, Batam Teknik Medan has established itself as a leading supplier of industrial goods in the region.

Suppliers of Compensators for Air Springs and Stainless Steel CNC Machining with Authentic Customer Reviews and Information

In the world of mechanical engineering, compensators are an essential component that plays a vital role in ensuring the smooth operation of various industrial processes. Compensators, in general, are used to compensate for thermal expansion or contraction, vibrations, and other mechanical stresses that may affect the overall performance of a given system.As such, the demand for high-quality compensators has risen over the years, with suppliers working tirelessly to ensure that they meet the growing needs of their customers. In response to this demand, the industry has seen a rise in the number of compensator suppliers, including those that specialize in air springs and stainless steel CNC machining.One such supplier is (brand name removed), which has been in the business of offering high-quality compensators to its customers for over a decade. The company's primary focus is on providing innovative solutions to customers, with a commitment to quality, reliability, and excellent customer service.One key area that the company has excelled in is providing air springs to its customers as a means of compensating for mechanical stress. Air springs are widely used in various industrial applications, including automotive, mining, and construction, to name a few. They offer a range of benefits, including stability, durability, and excellent load-carrying capacity.Another area where (brand name removed) has made remarkable strides is in stainless steel CNC machining. CNC machining is a computer-controlled process that involves the use of high-precision machines to manufacture complex parts and components. The process is highly accurate, with a level of precision that is hard to match using traditional machining methods.Stainless steel is a material that is widely used in various industrial applications due to its high strength, resistance to corrosion, and durability. As such, it is an ideal material for CNC machining, particularly for parts that require high precision and durability.The (brand name removed) team comprises highly skilled and experienced professionals who are committed to providing customers with the highest quality of products and services. The company uses the latest technology and techniques to manufacture its products, ensuring that they meet or exceed industry standards.In addition to providing high-quality air springs and CNC machining services, (brand name removed) also places a strong emphasis on customer service. The company believes that customer satisfaction is key to its continued success. As such, it goes the extra mile to ensure that its customers receive the best possible service, from initial contact through to post-sales support.The company's dedication to quality, innovation, and customer service has earned it an excellent reputation in the industry. Over the years, it has received numerous accolades and recognition for its outstanding products and services. It has also built strong relationships with its customers, many of whom have been with the company for years.In conclusion, the demand for high-quality compensators, including air springs and stainless steel CNC machining, continues to grow, with suppliers intensifying their efforts to meet the needs of their customers. (Brand name removed) is one such company that stands out in the industry, thanks to its commitment to quality, innovation, and customer service. With a team of highly skilled professionals and the latest technology, the company is well-positioned to continue providing its customers with the best possible products and services.

High-Quality Rubber Joint Pipes for Efficient Pipe Connections

Rubber Joint Pipe: Providing Excellent Performance and Quality Solutions to Different IndustriesRubber Joint Pipe is a well-known brand in the industry of flexible pipe connections. The company has been providing technical solutions and expertise for more than two decades, delivering rubber expansion joints, metallic expansion joints, and accessories for piping systems in different industries worldwide. The headquarters of Rubber Joint Pipe is located in Hong Kong with several manufacturing units around the world. The team of technical experts, engineers, and skilled workers ensure high-performance and reliable solutions to different projects.The company's products have been designed to accommodate different applications, such as water treatment, sewage systems, marine, chemical, power plants, construction, and HVAC. The rubber expansion joints are made of different materials, including NR, neoprene, EPDM, and Viton, each with specific features such as weather resistance, high temperature, oil resistance, and chemical resistance.One of the latest innovative products of Rubber Joint Pipe is the double-sphere rubber expansion joint, which is designed to handle a larger range of movements, misalignments, and vibrations. This expansion joint is composed of two spheres connected by a flexible rubber body, allowing for axial compression and extension, lateral and angular movements, and torsional flexibility. The double-sphere rubber expansion joint can also absorb and dampen vibrations, reducing noise and prolonging the lifespan of piping systems.The metallic expansion joints of Rubber Joint Pipe are also made of different materials, including stainless steel, carbon steel, and alloy steel, depending on the application and the specific requirements. The metallic expansion joints can accommodate higher temperatures and pressures, larger movements, and a longer lifespan than rubber expansion joints. The metallic expansion joints are also available in different configurations, such as single, double, and universal, with different types of bellows, such as convolution, annular, and multi-ply.Rubber Joint Pipe's team of technical experts and engineers can provide customized solutions and design services for different projects. The company uses advanced software for finite element analysis, 3D modeling, and stress calculation, ensuring the accuracy and reliability of the products. The company also adheres to international standards such as ISO, ASME, DIN, and ASTM, and collaborates with third-party inspectors for quality assurance and testing.Rubber Joint Pipe also offers a range of accessories such as flanges, tie rods, bolts, nuts, gaskets, and protective covers, ensuring a complete and reliable solution for piping systems. The company has a wide range of clients, including contractors, engineers, consultants, end-users, and distributors from different industries worldwide.Rubber Joint Pipe has built a strong reputation for providing excellent performance and quality solutions for flexible pipe connections. The company's products have been installed in different projects such as the sewage treatment plant in Malaysia, the chemical plant in Saudi Arabia, the power plant in Egypt, and the HVAC system in the USA. The company aims to keep innovating and improving its products and services to meet the ever-growing demand of the market and the customers.Rubber Joint Pipe's commitment to quality, reliability, innovation, and technical expertise has made it a leading player in the industry of flexible pipe connections. The company's products and services have been recognized and trusted by different clients worldwide. With its wide range of products, customized solutions, and excellent customer service, Rubber Joint Pipe is poised to meet and exceed the expectations of its customers in different industries.

Understanding the Import of Rubber Expansion Bellows Dimensions

Rubber Expansion Bellows Dimensions Facilitate Reliable Pressure Compensation in Various IndustriesIn today's world, where industrial applications require sophisticated machinery and equipment, the importance of reliable pressure compensation cannot be overstated. Industries such as petrochemicals, oil and gas, power generation, and wastewater management heavily rely on effective pressure management systems to ensure smooth operations and the safety of personnel.An essential component of these pressure management systems is the rubber expansion bellows - a flexible and durable tool designed to absorb vibrations and compensate for thermal expansion or contraction. These bellows play a crucial role in maintaining the structural integrity of pipelines, ventilation systems, and other industrial facilities, ensuring that potential damages and leakages are avoided.One of the leading manufacturers specializing in the production of premium rubber expansion bellows is a renowned company, known for its unwavering commitment to quality and innovation. With an extensive range of products, including flanged rubber expansion bellows, diaphragmatic expansion joints, and hinged expansion bellows, this company has earned a stellar reputation in the market for providing reliable and efficient solutions.The rubber expansion bellows offered by this company are carefully designed to meet diverse industrial requirements. However, mentioning brand names in the news article is not permissible, as per the guidelines. Therefore, let us refer to the company as "Company X." Their expansion bellows are manufactured using high-quality rubber materials that exhibit excellent resistance to chemicals, weathering, and extreme temperatures. This ensures durability and longevity, making them suitable for even the most demanding applications.One of the critical aspects when selecting rubber expansion bellows is the dimensions that need to be considered. Different industrial systems require bellows of specific sizes and shapes to maintain optimal pressure compensation. Company X recognizes this and offers an extensive range of dimensions to cater to various requirements.For instance, their flanged rubber expansion bellows are available in a wide range of nominal diameters, typically ranging from 25mm to 800mm, ensuring compatibility with various pipe sizes. Additionally, these bellows can accommodate axial, lateral, and angular movements, providing exceptional flexibility in installation. By employing precision manufacturing techniques, Company X ensures that all their bellows meet industry standards, guaranteeing a perfect fit and reliable performance.The diaphragmatic expansion joints manufactured by Company X are another notable product. These bellows are specifically designed to handle high pressures and demanding conditions. With their compact and lightweight design, they offer excellent resistance to torsion, axial, and lateral movements. The diaphragm's unique design ensures optimized pressure distribution, further enhancing the bellows' performance and longevity.Hinged expansion bellows, another specialized product offered by Company X, are engineered to facilitate easy installation and maintenance. These bellows are ideal for critical applications requiring frequent inspections or parts replacement. By incorporating a hinged mechanism, Company X ensures that these bellows can be conveniently opened or closed, reducing downtime and ensuring operational efficiency.It is worth mentioning that Company X not only takes pride in the quality of their products but also in their commitment to environmental preservation. They adhere to stringent environmental regulations during the manufacturing process, minimizing waste generation and reducing their carbon footprint. Moreover, the materials used in the production of their bellows are recyclable, ensuring a sustainable approach towards industrial solutions.With their exceptional expertise and dedication to customer satisfaction, Company X has successfully established a strong foothold in the market. Their rubber expansion bellows have been widely recognized for their reliability, durability, and efficiency. By offering a variety of dimensions and customizations, they meet the specific requirements of a wide range of industries.In conclusion, rubber expansion bellows are vital components in pressure management systems across various industries. Company X, a prominent manufacturer in this sector, produces high-quality bellows that ensure reliable pressure compensation. With a wide range of dimensions and innovative designs, their products cater to diverse industrial needs. By prioritizing quality, efficiency, and environmental sustainability, Company X stands out as a trusted partner for industries requiring reliable pressure management solutions.

Expert Assembly of Hydraulic and Pneumatic Systems In-House, Including Rare Components

and Air Hydro Power.As industries continue to evolve, the demand for highly advanced machinery and equipment rises. Among these machines and equipment, there is one vital component that allows for smooth and efficient operation – hydraulic expansion joints.At Air Hydro Power, we specialize in providing high-quality hydraulic expansion joints that cater to the needs of various industries. We take pride in our expertise in building each assembly in-house, using only the best materials available in the market.What are hydraulic expansion joints?Before discussing the benefits of hydraulic expansion joints, it is essential to understand what they are, how they work, and their different types.Hydraulic expansion joints are essential components of hydraulic systems that enable the smooth and efficient transfer of fluids. They are designed to compensate for misalignments and absorb vibrations, thereby preventing damage to the system's components and ensuring its longevity.The working principle behind hydraulic expansion joints is based on their capability of stretching and contracting under pressure and temperature variations. By doing so, they help absorb the shock that occurs when fluids circulate in the system.Different Types of Hydraulic Expansion Joints1. Axial Expansion JointsAxial expansion joints are designed to allow axial (longitudinal) movement within the hydraulic systems. They are ideal for applications requiring the transfer of fluid from one point to another using pipelines.2. Lateral Expansion JointsUnlike axial expansion joints, lateral expansion joints are ideal for transferring fluids in circuits that require lateral (horizontal) movement. They are ideal for applications where pipelines run parallel to each other.3. Angular Expansion JointsSometimes, systems require fluid transfer from a pipeline in one direction to another at an angle. This is where angular expansion joints come in handy. They are designed to absorb angular movements that occur in hydraulic systems.Benefits of Hydraulic Expansion Joints1. Reduction of VibrationsVibrations can be detrimental to hydraulic systems, causing component wear and tear, damage, and even malfunction. Hydraulic expansion joints are designed to reduce these vibrations and absorb any shock that could cause harm to the system's components.2. Compensation for MisalignmentsMisalignments occur when two different pipelines' axes fail to align, causing strain on one of the pipelines or both. This can lead to the premature failure of the system's components. Hydraulic expansion joints are designed to compensate for these misalignments, keeping the system running smoothly and efficiently.3. Longevity of EquipmentHydraulic expansion joints help in mitigating the wear and tear of hydraulic systems, ensuring their longevity. By reducing vibrations, absorbing shock, and compensating for misalignments, the system's components are less likely to fail prematurely.Why Choose Air Hydro Power?At Air Hydro Power, we pride ourselves in providing high-quality hydraulic expansion joints that cater to a wide range of industries. Our team of experts carefully examines each component before assembly to ensure that we only use the best materials available in the market.Our in-house assembly and stocking of standard and hard-to-find components mean that your orders are processed quickly and efficiently. At Air Hydro Power, we are committed to providing exceptional customer support and excellent service.In conclusion, hydraulic expansion joints play a crucial role in the smooth and efficient operation of hydraulic systems. At Air Hydro Power, we have made it our mission to provide high-quality components that meet the demands of various industries. Our industry experience, in-house assembly, and excellent customer service make us the perfect partner for your hydraulic expansion joint needs.

New Pump Bellows Connectors Offer Improved Seal for Safe Industrial Operations

Title: Pump Bellows Connectors: Providing Efficient and Reliable Solutions for the IndustryIntroduction:In today's fast-paced industrial landscape, the efficiency and reliability of machinery and components are crucial for seamless operations. One such integral component is the Pump Bellows Connector, a vital innovation that ensures optimal functioning of pumps in various industries. This article delves into the significance of Pump Bellows Connectors and highlights the noteworthy contributions of a renowned manufacturing company in this field.I. Understanding Pump Bellows Connectors:Pump Bellows Connectors are flexible, expansion joints designed to absorb vibrations, compensate for thermal expansion, and reduce stress on piping systems. These connectors act as a link between the pump and the pipeline, allowing for movement and expansion while maintaining a tight seal. Their flexibility and versatility make them an indispensable component for various industries, including oil and gas, chemical processing, water treatment, and power generation.II. The Role of Pump Bellows Connectors:1. Absorbing Vibrations: Pump vibrations can lead to machinery damage and reduced equipment lifespan. Pump Bellows Connectors effectively dampen vibrations, minimizing system stress and enabling quieter operations. This feature translates into fewer maintenance needs and enhanced equipment longevity.2. Compensating for Thermal Expansion: Piping systems often experience thermal expansion due to the temperature variations in industrial processes. By accommodating these movements, Pump Bellows Connectors prevent stress, cracks, and leaks in the system. This ability to compensate for thermal expansion ensures the uninterrupted flow of fluids, preventing potential disruptions and failures.3. Reducing Stress on Piping Systems: Pump Bellows Connectors serve as a flexible joint between the pump and the piping system. This flexibility allows for the absorption of movements caused by misalignment, pump vibrations, or thermal expansion. As a result, stress on pipes and associated connections is greatly reduced, minimizing the risk of leaks and maintaining system integrity.III. The Leading Manufacturer:[List the brand name] is a reputable manufacturer with a proven track record in providing high-quality Pump Bellows Connectors. With a commitment to innovation and customer satisfaction, [Brand Name] has become a trusted name in the industry. Their team of experts combines extensive knowledge with cutting-edge technology to deliver connectors that meet and exceed industry standards.1. Quality Assurance: [Brand Name] employs stringent quality control measures throughout the manufacturing process. Each Pump Bellows Connector undergoes rigorous inspections and testing to ensure its durability, reliability, and compliance with industry specifications. The company's dedication to quality has earned them a solid reputation among industry professionals.2. Customization and Efficiency: Recognizing the diverse needs of different industries, [Brand Name] offers customized solutions for specific applications. The company's team of skilled engineers works closely with clients to design Pump Bellows Connectors that precisely meet their requirements. This tailored approach ensures optimal performance, reduced maintenance, and enhanced efficiency in every application.IV. Benefits and Applications:1. Benefits of Pump Bellows Connectors: Pump Bellows Connectors provide numerous benefits, including improved system performance, extended equipment life, reduced maintenance costs, and enhanced safety. The usage of these connectors leads to increased productivity, decreased downtime, and enhanced overall productivity for various industrial processes.2. Applications: Pump Bellows Connectors find extensive applications in a wide range of industries. They are commonly used in chemical plants, power generation facilities, oil refineries, water treatment plants, and pharmaceutical facilities. Their versatility allows for seamless integration into different systems, making them an essential component in ensuring efficient and reliable operations.V. Conclusion:Pump Bellows Connectors play a critical role in maintaining the efficiency, reliability, and safety of industrial machinery and piping systems. As seen through the contributions of [Brand Name], the manufacturing of these connectors requires precision and expertise. With continuous innovation and a commitment to customer satisfaction, [Brand Name] has established itself as a leading provider of high-quality Pump Bellows Connectors, serving a wide array of industries effectively.

Effective Solutions for Rubber Expansion Joints with Threaded Unions

Title: Innovative Threaded Union Rubber Expansion Joint Sets New Standards in Industrial Piping Solutions Introduction (100 words):In the constantly evolving field of industrial piping solutions, a pioneering company has emerged with a groundbreaking product that is revolutionizing the industry. Threaded Union Rubber Expansion Joint, developed by an industry-leading company, offers an innovative and efficient solution for pipe connection applications. Boasting exceptional performance, flexibility, and durability, this expansion joint is set to redefine the market, providing engineers and professionals across a wide range of sectors with a reliable and high-quality solution.Body:1. The Importance of Robust Pipe Connections (150 words):Ensuring reliable and leak-free pipe connections is crucial for industrial applications. Piping systems are used extensively across industries such as chemical, petrochemical, oil and gas, wastewater treatment, power generation, and HVAC. Failure in these systems can lead to significant operational disruptions, financial losses, and even safety hazards. Hence, industry professionals constantly seek better solutions to enhance the stability, flexibility, and longevity of their pipe connections.2. Introducing Threaded Union Rubber Expansion Joint (150 words):Threaded Union Rubber Expansion Joint is an advanced product that addresses the challenges faced by industrial piping systems. Built on cutting-edge technology, this expansion joint is designed to provide exceptional performance and reliability in demanding environments. The joint combines rubber and metal components to form a flexible connection that can absorb vibrations, compensate for thermal expansion, and reduce noise.3. Key Features and Benefits (200 words):a. Versatility: Threaded Union Rubber Expansion Joint caters to different pipe materials, diameters, and working pressures. It can be adapted to various installation requirements, making it suitable for a wide range of industrial applications.b. Flexibility: The joint's elastomeric construction allows it to absorb movement and stress, compensating for thermal expansion, contraction, and misalignment. This flexibility minimizes the risk of pipe failure and reduces fatigue on the system, extending the lifespan of the overall piping network.c. Enhanced Durability: The joint's robust design ensures resilience to harsh operating conditions, such as exposure to chemicals, high temperatures, and corrosive substances. This makes it ideal for industries that demand long-lasting and reliable performance.d. Noise and Vibration Reduction: The joint significantly reduces the transmission of noise and vibrations, enhancing safety and creating a quieter working environment.e. Easy Installation and Maintenance: Threaded Union Rubber Expansion Joint features a user-friendly design that simplifies installation, with reduced downtime and no special tools required. Routine maintenance is straightforward, ensuring hassle-free upkeep of the piping system.4. Market Impact and Future Prospects (150 words):The introduction of Threaded Union Rubber Expansion Joint is poised to create a significant impact on the market for industrial piping solutions. With its superior capabilities, the joint can enhance the operational efficiency, reliability, and safety of a wide range of industries. The product's potential to reduce downtime, minimize maintenance costs, and extend the service life of the piping system makes it an appealing choice for engineers and professionals.Looking ahead, this innovative expansion joint is expected to contribute to the ongoing development of high-performance piping systems, offering a sustainable and cost-effective solution. In a rapidly growing industrial landscape, where reliability and robustness are essential, Threaded Union Rubber Expansion Joint sets a new benchmark for the industry, ensuring seamless pipe connections that are built to withstand the most challenging conditions.Conclusion (100 words):Threaded Union Rubber Expansion Joint offers an innovative solution for industrial piping systems, providing a combination of exceptional performance, versatility, and reliability. With its ability to absorb stress, reduce noise and vibrations, and resist the harshest operating conditions, this expansion joint is set to redefine the industry standards. As professionals across various industrial sectors demand reliable and robust piping solutions, the Threaded Union Rubber Expansion Joint emerges as a game-changer, revolutionizing the way we approach pipe connections.

Guide to 8 Inch Expansion Joints: All You Need to Know

8 Inch Expansion Joint Market to Witness Growth Acceleration during 2022-2027The global 8 Inch Expansion Joint market is expected to experience significant growth in the coming years, according to a new report by Market Research Future (MRFR). The report provides a comprehensive analysis of the market, including current trends, drivers, restraints, and opportunities for growth. The 8 Inch Expansion Joint market is projected to expand at a CAGR of XX% during the forecast period 2022-2027.Expansion joints are essential components in various industries, including oil and gas, petrochemical, power generation, and water treatment. These joints are designed to absorb movements and vibrations caused by thermal expansion, mechanical loads, and other forces, thereby extending the lifespan of piping systems and preventing leaks and structural damage. The demand for 8 Inch Expansion Joints is expected to surge as industries continue to invest in infrastructure development and maintenance.One of the key players in the 8 Inch Expansion Joint market, {Company Name}, specializes in manufacturing high-quality expansion joints for a wide range of applications. With decades of experience and expertise in engineering and design, {Company Name} has established itself as a leading supplier of expansion joints globally. The company's commitment to innovation and customer satisfaction has enabled it to carve a niche in the competitive market.The 8 Inch Expansion Joint market is driven by several factors, including the growing need for reliable piping systems in industrial facilities, stringent regulations for safety and environmental protection, and the increasing investments in infrastructure projects. As industries strive to enhance operational efficiency and reduce downtime, the demand for high-performance expansion joints is expected to escalate. Additionally, the expansion of the oil and gas, chemical, and power generation sectors is anticipated to fuel the growth of the 8 Inch Expansion Joint market.Moreover, the rising awareness about the importance of preventive maintenance and the benefits of using advanced expansion joints in industrial processes is likely to drive the market further. Expansion joints play a critical role in ensuring the integrity and reliability of piping systems, which is paramount for the smooth operation of industrial plants. As a result, end-users are increasingly recognizing the value of investing in quality expansion joints to mitigate the risk of mechanical failures and costly repairs.In terms of regional analysis, North America and Europe are expected to dominate the 8 Inch Expansion Joint market, owing to the presence of a large number of industrial facilities and the implementation of stringent safety standards in these regions. The Asia-Pacific region is projected to exhibit substantial growth, attributed to the rapid industrialization and infrastructure development in countries such as China, India, and Japan. The Middle East and Africa region is also anticipated to offer lucrative opportunities for the expansion joint market, supported by the flourishing oil and gas industry and ongoing infrastructure projects.To capitalize on the growing demand for 8 Inch Expansion Joints, {Company Name} continues to focus on research and development to enhance its product offerings and cater to diverse customer requirements. The company's commitment to delivering superior quality expansion joints, coupled with its strong distribution network and customer-centric approach, positions it as a preferred choice for end-users across various industries.In conclusion, the global 8 Inch Expansion Joint market is poised for substantial growth in the foreseeable future, driven by the increasing need for reliable piping systems and the expansion of industrial sectors. With its proven track record and dedication to innovation, {Company Name} is well-positioned to capitalize on the opportunities presented by the burgeoning market and further strengthen its position as a leading provider of high-performance expansion joints.