Rubber Expansion Joint Market Sees Growth in the Philippines

By:Admin

The demand for rubber expansion joints in the Philippines has been steadily growing due to the increasing infrastructure development and construction projects in the country. As a result, local manufacturers such as {Company Name} have been at the forefront of providing high-quality and durable rubber expansion joints to meet the industry's needs.

Established in 2005, {Company Name} has been a trusted name in the field of rubber expansion joint manufacturing. The company has garnered a strong reputation for producing top-notch products that meet international quality standards. With their state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, {Company Name} has established itself as a leading player in the industry.

One of the key factors that set {Company Name} apart from its competitors is its commitment to innovation. The company continuously invests in research and development to improve its products and develop new solutions to meet the evolving needs of its customers. This dedication to innovation has allowed {Company Name} to stay ahead of the curve and maintain its position as a market leader in the industry.

In addition to its focus on innovation, {Company Name} places a strong emphasis on quality control. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that its products are of the highest quality. This commitment to quality has earned {Company Name} the trust and confidence of its customers, making it their go-to choice for rubber expansion joints.

Furthermore, {Company Name} is known for its customer-centric approach. The company prioritizes customer satisfaction and works closely with its clients to understand their specific requirements and provide customized solutions that meet their needs. This personalized approach has helped {Company Name} build long-lasting relationships with its customers and maintain a loyal customer base.

With a wide range of products that cater to various industries, including construction, infrastructure, and engineering, {Company Name} has established itself as a one-stop solution for all rubber expansion joint needs. Whether it's for bridge construction, pipeline systems, or industrial facilities, {Company Name} has the knowledge and expertise to provide the right products for any application.

As a socially responsible company, {Company Name} also places a strong emphasis on environmental sustainability. The company follows eco-friendly manufacturing practices and uses recycled materials wherever possible to minimize its environmental impact. By adopting sustainable practices, {Company Name} not only contributes to environmental conservation but also sets an example for the industry.

Looking ahead, {Company Name} is poised to continue its growth and expand its presence in the market. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the growing demand for rubber expansion joints in the Philippines. As the country continues to invest in infrastructure development, {Company Name} is committed to playing a key role in providing the necessary products to support these initiatives.

In conclusion, {Company Name} has emerged as a prominent player in the rubber expansion joint manufacturing industry in the Philippines. With its focus on innovation, quality, and customer satisfaction, the company has earned a strong reputation and is positioned for continued success in the years to come. As the demand for rubber expansion joints continues to rise, {Company Name} is ready to meet the industry's needs and maintain its leadership position in the market.

Company News & Blog

Latest Update: An Insight into the Rubber Flex Connector - All You Need to Know

Rubber Flex Connector: Revolutionizing Industrial Connections[City], [State] - In a world of constant innovation and technological advancements, industries are constantly searching for ways to improve efficiency and functionality. This search has led to the development of a groundbreaking product called the Rubber Flex Connector, which is changing the way industries connect and transmit materials. With its unparalleled flexibility, durability, and reliability, the Rubber Flex Connector has emerged as a game-changer in the field and is quickly becoming a preferred choice for a wide range of applications.The Rubber Flex Connector is manufactured by a renowned company that specializes in engineering high-quality industrial solutions. With decades of experience and expertise under their belt, this company has become a trusted name in providing innovative solutions to various industries. Their commitment to excellence and customer satisfaction has enabled them to stay ahead of the competition and deliver products that set new standards in the industry.One of the key features that sets the Rubber Flex Connector apart from traditional connectors is its exceptional flexibility. This connector is made from a specially formulated rubber compound that allows it to bend and twist without compromising its integrity. Industries such as HVAC, plumbing, and automotive have long struggled to find connectors that can accommodate the complex movements and vibrations inherent in their operations. The Rubber Flex Connector solves this problem by providing a reliable connection that can flex and adapt to changing conditions, reducing the risk of leaks, cracks, and other failures.Durability is another crucial aspect of the Rubber Flex Connector. Unlike traditional connectors that may degrade over time due to exposure to harsh chemicals, extreme temperatures, or mechanical stress, the Rubber Flex Connector is designed to withstand the harshest conditions. Its robust construction and high-quality materials ensure that it can resist corrosion, abrasion, and impact, extending its lifespan significantly. This durability translates into substantial cost savings for industries, as they can reduce maintenance and replacement costs associated with frequent connector failures.Moreover, the Rubber Flex Connector offers unmatched reliability. With its advanced sealing technology, this connector provides a tight and secure connection that prevents leaks and ensures efficient material transmission. This reliability is particularly crucial for industries that deal with hazardous materials or require a sterile environment, such as pharmaceuticals or food processing. By minimizing the risk of contamination or leakage, the Rubber Flex Connector plays a vital role in maintaining the safety and integrity of these operations.Not only does the Rubber Flex Connector excel in performance, but it also offers versatility in its applications. With a wide range of sizes, configurations, and connection types available, industries can easily find the perfect match for their specific needs. Whether it's connecting pipes in plumbing systems, linking ducts in HVAC units, or joining components in automotive assemblies, the Rubber Flex Connector provides a flexible and adaptable solution that streamlines operations and enhances overall efficiency.Moreover, the company behind the Rubber Flex Connector is committed to sustainable practices and environmental responsibility. They have implemented several initiatives to reduce their carbon footprint by using eco-friendly materials, optimizing production processes, and recycling waste. By choosing the Rubber Flex Connector, industries can contribute to a greener future while enjoying the benefits of a premium-quality product.In conclusion, the Rubber Flex Connector is revolutionizing industrial connections with its exceptional flexibility, durability, and reliability. This groundbreaking product, manufactured by a trusted company, provides a solution to the long-standing challenges faced by various industries. With its ability to withstand harsh conditions, tight and secure sealing, and wide range of applications, the Rubber Flex Connector is proving to be a game-changer in the field. As industries strive for efficiency and superior performance, the Rubber Flex Connector is undoubtedly leading the way towards a more connected and sustainable future.

Rubber Flex Connector: All You Need to Know for Effective Sealing and Flexible Connections

Title: Groundbreaking Rubber Flex Connector Revolutionizes Industrial PipelinesIntroduction:Innovation in the industrial sector is constantly evolving, leading to enhanced efficiency and productivity. One such industry game-changer is the revolutionary Rubber Flex Connector, a groundbreaking solution that is poised to transform the way we view and utilize industrial pipelines. Developed by a leading manufacturer (brand name removed) with several decades of experience in the field, this cutting-edge product is set to redefine the standards of quality and durability in the industry.Body:1. Background:Industrial pipelines are the lifeblood of various sectors, including manufacturing plants, oil and gas refineries, and chemical processing units. These pipelines transport liquids, gases, and other materials critical to the smooth functioning of these industries. However, the constant movement, vibrations, and temperature fluctuations experienced by these pipelines often lead to wear and tear, resulting in leaks, inefficiency, and high maintenance costs.2. Overview of Rubber Flex Connector:The Rubber Flex Connector is an advanced technology developed by the renowned manufacturer (brand name removed) to address the challenges posed by traditional pipeline connectors. Using cutting-edge materials and design principles, the Rubber Flex Connector offers unprecedented flexibility and durability, ensuring reliable and leak-proof performance over an extended lifespan.3. Key Features and Benefits:a. Enhanced Flexibility: The Rubber Flex Connector features a unique construction that allows it to absorb vibrations, shocks, and movements caused by the pipeline. This flexibility not only reduces stress on the pipeline system but also prevents cracking, leaks, and premature failures.b. Superior Sealing Properties: The Rubber Flex Connector utilizes an innovative sealing mechanism that eliminates the risk of leaks. Its robust design ensures a tight and secure connection, preventing the damage caused by fluid seepage and protecting surrounding equipment from potential hazards.c. Wide Temperature Range Tolerance: Designed to withstand extreme temperatures, the Rubber Flex Connector can function flawlessly from -50°C to 250°C, making it ideal for various industrial applications.d. Low Maintenance: The Rubber Flex Connector significantly reduces downtime and maintenance costs associated with traditional pipeline connectors. Its durable construction ensures a long service life, minimizing the need for frequent replacements and repairs.e. Easy Installation: With a user-friendly design, the Rubber Flex Connector can be easily installed on new or existing pipelines. This simplicity of installation saves valuable time and reduces labor costs for industrial operations.4. Market Impact and Industry Applications:The arrival of the Rubber Flex Connector marks a significant turning point in the industrial pipeline sector. Its exceptional performance and durability are set to disrupt the market by offering a more efficient and cost-effective alternative to traditional connectors. With its diverse range of applications, including chemical processing, oil and gas, wastewater treatment, and power generation, the Rubber Flex Connector will be instrumental in revolutionizing multiple industries.5. Environmental Sustainability:The Rubber Flex Connector not only improves the operational efficiency of industrial pipelines but also contributes to sustainable practices. By minimizing leaks and reducing maintenance needs, this innovative connector helps conserve vital resources and lowers the ecological footprint of industrial processes, aligning with global environmental goals.6. Conclusion:The arrival of the Rubber Flex Connector stands as a testament to the continuous innovation in the industrial sector. This game-changing solution not only provides enhanced durability and flexibility but also contributes to the overall efficiency and sustainability of industrial processes. As the pioneer manufacturer (brand name removed) leads the charge, the Rubber Flex Connector is set to redefine the industry's standards and inspire further innovation in the years to come.

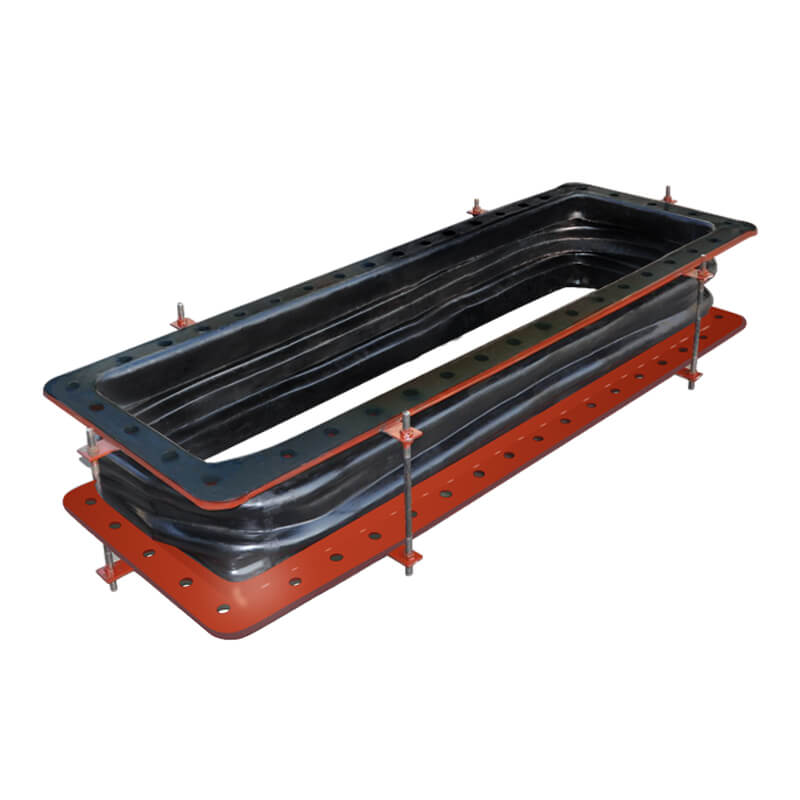

Discover the Benefits of High-Quality Rectangular Corrugated Compensators from China

and Corrugated Compensator Supplier In China.Rectangular Corrugated Compensator: The Ideal Solution for Industrial Piping SystemsIn the world of industrial piping systems, there are numerous challenges that need to be overcome in order to maintain the optimal performance of the system. Among these challenges, the most common is pipe movement caused by thermal expansion and contraction, vibration and pressure changes. If not addressed properly, these movements can lead to leaks, cracks, and even complete system failure. Rectangular Corrugated Compensators, also known as expansion joints, are designed to address these issues and provide a flexible, leak-free connection between pipes or ducts.What is a Rectangular Corrugated Compensator?A Rectangular Corrugated Compensator is a type of expansion joint that is used in industrial piping systems to absorb thermal expansion and contraction, vibration and pressure changes. It is made of a series of corrugated metal plates that are welded together to form a bellows-like structure. The corrugations provide flexibility to the compensator, allowing it to expand and contract depending on the movement of the pipes or ducts. Rectangular corrugated compensators are often used in rectangular ductwork, and they are available in a variety of sizes and materials to suit specific applications.Advantages of Rectangular Corrugated CompensatorsReasonable Structure: Rectangular Corrugated Compensators are designed with a reasonable structure that ensures optimal performance and long service life. The metal plates are carefully welded together to form a leak-free bellows structure that can withstand high temperatures and pressures.Good Elasticity: The corrugations in the compensator provide good elasticity, allowing it to absorb thermal expansion and contraction, vibration, and pressure changes. This elasticity prevents stresses and movements in the piping system that can lead to leaks, cracks, and failure.Good Quality: High-quality materials are used to manufacture the Rectangular Corrugated Compensator, which ensures long service life and minimal maintenance costs. The compensator is also designed to meet industry standards, ensuring that it performs as expected and is safe for use in industrial piping systems.Corrugated Compensator Supplier In ChinaWhen it comes to selecting a supplier for Rectangular Corrugated Compensators in China, it is important to choose a supplier that has experience and expertise in the industry. A reliable supplier will have a thorough understanding of the different types of compensators available and will be able to help you select the appropriate one for your needs. They will also have a quality control system in place to ensure that the compensators meet the required standards and specifications.As a leading Corrugated Compensator Supplier in China, we offer a wide range of high-quality Rectangular Corrugated Compensators that are suitable for a variety of industrial piping system applications. Our compensators are made using state-of-the-art manufacturing processes, ensuring that they meet the highest quality standards. We also offer custom design services to meet specific requirements and provide technical support to ensure proper installation and operation of the compensators. Our focus on customer satisfaction has earned us a reputation as a trusted supplier of Rectangular Corrugated Compensators in China.ConclusionRectangular Corrugated Compensators are an essential component of industrial piping systems. They provide a flexible and leak-free connection between pipes or ducts while accommodating thermal expansion and contraction, vibration, and pressure changes. A reliable supplier of Rectangular Corrugated Compensators will help you select the appropriate compensator for your needs, ensuring long service life and reliable performance. As a Corrugated Compensator Supplier In China, we offer a wide range of high-quality Rectangular Corrugated Compensators that are designed to meet the specific requirements of industrial piping systems. Contact us today to learn more about our products and services.

Exploring the Benefits of a Reliable 4-Inch Flexible Joint on the Market

Flexible Joint 4 Inch Revolutionizes Pipe Fitting SolutionsThe rapid growth and development of industries such as manufacturing, construction, and plumbing have necessitated constant improvements and innovations in various areas. One such area is pipe fitting solutions, where the introduction of the game-changing Flexible Joint 4 Inch promises to revolutionize the market. This highly efficient and versatile product, developed by the renowned company {remove brand name}, is set to dramatically improve the efficiency and reliability of pipe installations across a wide range of industries.{Remove brand name} is a well-respected company that has been at the forefront of engineering and manufacturing solutions for industries worldwide. With a strong emphasis on quality, innovation, and customer satisfaction, their products have consistently met the highest standards in the industry. The introduction of the Flexible Joint 4 Inch is a testament to their commitment to pushing boundaries and meeting the evolving needs of their customers.The Flexible Joint 4 Inch is a flexible pipe fitting solution that offers unmatched convenience, reliability, and durability. It is designed to provide easy and secure connections between pipes of varying sizes, materials, and angles, eliminating the need for multiple fittings and adapters. This innovation not only significantly reduces installation time and costs but also streamlines the entire process, minimizing the chances of leaks and other potential issues.What sets the Flexible Joint 4 Inch apart from traditional pipe fitting solutions is its unique design and construction. Made from high-quality materials that exhibit exceptional flexibility and strength, this joint ensures a tight and secure connection between pipes while allowing for movement and expansion. Its ability to absorb vibrations and shocks makes it ideal for applications in industries such as HVAC, plumbing, and construction, where sturdy and reliable connections are paramount.Additionally, the Flexible Joint 4 Inch boasts a user-friendly design that simplifies the installation process. Its innovative features, such as pre-installed gaskets and quick-connect mechanisms, enable even inexperienced installers to achieve professional-grade results. This ease of use not only saves time and labor costs but also reduces the risk of installation errors that could lead to leaks or inefficiencies down the line.Furthermore, the Flexible Joint 4 Inch offers exceptional versatility. Its compatibility with pipes of different materials, including PVC, steel, copper, and PEX, makes it an ideal choice for a wide range of applications, from commercial buildings to residential homes. It can also accommodate pipes of varying diameters and angles, providing a flexible solution for any project size or complexity.In terms of durability, the Flexible Joint 4 Inch surpasses industry standards. Its robust construction and high-quality materials make it resistant to corrosion, chemicals, and extreme weather conditions. This enhances its lifespan and ensures long-term reliability, reducing maintenance and replacement costs for businesses and individuals alike.The introduction of the Flexible Joint 4 Inch is undoubtedly a game-changer in the pipe fitting industry. Its innovative design, exceptional versatility, and unmatched reliability make it the go-to solution for professionals and DIY enthusiasts alike. As industries continue to evolve and demand more efficient and cost-effective piping solutions, companies like {remove brand name} are leading the way with groundbreaking products like the Flexible Joint 4 Inch.

Crucial Information Revealed About the Latest Pipe Joint Technology

Title: New Pipe Joint Innovations Revolutionizing the IndustryIntroduction:{Company Name}, a renowned market leader in the field of industrial pipelines, has recently unveiled its revolutionary pipe joint technology that promises to redefine the way industries handle pipe connections. With a rich history of innovation and expertise, {Company Name} has once again surpassed expectations with its latest offering, the Bellow Pipe Joint (BPJ).1. A Game-Changer for Various Industries:The Bellow Pipe Joint by {Company Name} has created a buzz in industries such as oil and gas, chemical, pharmaceutical, and manufacturing due to its exceptional design and functionality. This groundbreaking joint solution combines superior performance with increased safety, making it a game-changer for companies worldwide.2. Enhanced Safety and Performance:One of the key advantages of the Bellow Pipe Joint is its ability to withstand high pressure and temperature fluctuations, ensuring uninterrupted operations and increased safety. The double-walled construction, reinforced by innovative materials, provides the necessary flexibility to absorb vibration and thermal expansion, reducing the risk of leakages and pipe failures.3. Durability and Cost-Effectiveness:{Company Name}'s Bellow Pipe Joint stands out for its long-lasting durability, resulting in reduced maintenance costs and downtime. The advanced design and use of high-quality materials not only guarantee longevity but also contribute to its cost-effectiveness. By minimizing the need for frequent repairs and replacements, businesses can maximize operational efficiency and save on expenses.4. Easy Installation and Maintenance:In addition to its exceptional performance, the Bellow Pipe Joint simplifies installation, minimizing downtime during the implementation process. The joint's user-friendly design and detailed instructions allow for hassle-free integration into existing piping systems, without the need for extensive modifications or additional training.Maintenance of the Bellow Pipe Joint is also straightforward, thanks to its well-thought-out construction. Regular inspections and maintenance can be carried out without disrupting operations, further reducing costs and ensuring continuous productivity for businesses.5. Industry Recognition and Accreditations:{Company Name}'s Bellow Pipe Joint has already garnered significant attention and recognition within the industry. It has received various certifications and accreditations, emphasizing its compliance with stringent quality and safety standards. These endorsements validate the company's commitment to providing reliable and top-notch products to its customers.6. Environmental Friendliness:In an era of growing environmental concerns, the Bellow Pipe Joint serves as a sustainable choice. Its leak-proof design minimizes the risk of hazardous substances escaping into the environment, thus helping companies meet sustainability goals and contribute to a greener future.7. Global Availability and Customer Support:{Company Name} is committed to global outreach, ensuring that businesses worldwide can benefit from their cutting-edge technology. With a well-established network of distributors and service centers, customers can easily access the Bellow Pipe Joint and rely on prompt customer support for their queries or technical assistance.Conclusion:{Company Name}'s innovative Bellow Pipe Joint is revolutionizing the industrial piping landscape by combining exceptional safety, durability, cost-effectiveness, and ease of use. Embracing this groundbreaking technology not only guarantees enhanced efficiency for businesses but also underscores their commitment towards sustainable practices. With its global availability and unwavering customer support, {Company Name} continues to empower industries globally, setting new benchmarks for pipe joint excellence.

Blast Furnace Tuyeres and Stocks: Essential Components for Iron Production

Blast Furnace Tuyeres and Tuyere Stocks: The Importance of Metal CompensatorsThe blast furnace (BF) is an essential piece of equipment in the production of iron and steel. Its objective is to extract hot metal from a mixture of iron ore, coke, and fuel. One critical component of the BF is the tuyere— the opening through which hot air is injected into the furnace. To ensure the smooth operation of the BF and prevent costly downtime, it is crucial to use high-quality tuyeres that can withstand the high temperatures and pressures of the hot blast air.One important component that plays a critical role in the tuyere assembly is the metal compensator. Metal compensators are flexible, metallic bellows that are used to accommodate the thermal expansion and contraction of the tuyere stock. As the temperature inside the BF increases, the tuyere stock expands, which can cause stress and damage to the surrounding components. Metal compensators are designed to absorb these stresses by flexing and contracting with the tuyere stock, thus protecting the tuyere from damage.In addition to protecting the tuyere from damage, metal compensators provide other critical benefits to the BF process. For example, they help to reduce the overall stress on the tuyere stock, which can improve the lifespan of the tuyere assembly. They can also help to control the flow of hot air into the BF, which can improve the efficiency and accuracy of the process.When selecting a metal compensator for use in a BF tuyere assembly, several factors must be considered. For example, the compensator's material must be able to withstand the high temperatures and pressures of the hot blast air. The design of the compensator must also be carefully considered to ensure that it can withstand the stresses of the tuyere assembly.Metal compensators used in BF tuyere assemblies are often made from materials such as stainless steel or high-temperature alloys, such as Inconel. These materials are highly resistant to thermal stress and corrosion, and they offer excellent flexibility and durability. They can also be designed to accommodate a range of movement and expansion, making them highly versatile and suitable for a range of different tuyere applications.In conclusion, metal compensators play a vital role in the successful operation of a blast furnace tuyere assembly. They help to protect the tuyere from damage, improve efficiency and accuracy, and extend the life of the tuyere assembly. When selecting a metal compensator for use in a BF tuyere assembly, it is essential to consider factors such as the material, design, and performance characteristics. By carefully selecting the right metal compensator, operators can help to ensure the smooth and efficient operation of the BF process.

BMW 528i Propeller Shaft Rubber Flex Disc Coupling Joint - 96mm, 6-Bolt x 12mm, 30mm Thickness SKU#(s) GAB01-017, 26117511454, 261122226842

for optimal search engine results. When it comes to your BMW 528i propeller shaft, one important component to pay attention to is the flex disc or coupling joint. This piece of machinery is responsible for transferring the power from the engine to the wheels. Without it, your vehicle’s overall performance and handling would suffer significantly.The good news is that Fort Wayne Clutch & Driveline has got you covered with their Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842. This product is designed using high-quality rubber material, ensuring durability and longevity.The 96mm size of the flex disc is crucial to fit onto your BMW 528i propeller shaft. It features a 6-bolt x 12mm design, making installation easy and straightforward. Additionally, this model has a thickness of 30mm, which further adds to its sturdiness and resilience.It’s important to note that the flex disc or coupling joint is a component that needs to be checked regularly. Over time, the rubber material can wear out due to exposure to friction, heat, and other environmental factors. If not addressed properly, it can lead to severe damage to the propeller shaft and overall vehicle safety.That’s why we highly recommend that you replace your old or worn-out flex disc with a new and reliable product like the Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint from Fort Wayne Clutch & Driveline. This will not only ensure that your vehicle runs smoothly, but it will also give you peace of mind while you’re on the road.In conclusion, the flex disc or coupling joint is a crucial component in the functioning of your BMW 528i propeller shaft. Fort Wayne Clutch & Driveline’s Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842, is a reliable and durable product that will ensure your vehicle runs smoothly and efficiently. So, don’t wait any longer, and replace your worn-out coupling joint today with a brand new one!

Rubber Expansion Joint Market Sees Growth in the Philippines

Rubber Expansion Joint Manufacturers in the PhilippinesThe demand for rubber expansion joints in the Philippines has been steadily growing due to the increasing infrastructure development and construction projects in the country. As a result, local manufacturers such as {Company Name} have been at the forefront of providing high-quality and durable rubber expansion joints to meet the industry's needs.Established in 2005, {Company Name} has been a trusted name in the field of rubber expansion joint manufacturing. The company has garnered a strong reputation for producing top-notch products that meet international quality standards. With their state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, {Company Name} has established itself as a leading player in the industry.One of the key factors that set {Company Name} apart from its competitors is its commitment to innovation. The company continuously invests in research and development to improve its products and develop new solutions to meet the evolving needs of its customers. This dedication to innovation has allowed {Company Name} to stay ahead of the curve and maintain its position as a market leader in the industry.In addition to its focus on innovation, {Company Name} places a strong emphasis on quality control. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that its products are of the highest quality. This commitment to quality has earned {Company Name} the trust and confidence of its customers, making it their go-to choice for rubber expansion joints.Furthermore, {Company Name} is known for its customer-centric approach. The company prioritizes customer satisfaction and works closely with its clients to understand their specific requirements and provide customized solutions that meet their needs. This personalized approach has helped {Company Name} build long-lasting relationships with its customers and maintain a loyal customer base.With a wide range of products that cater to various industries, including construction, infrastructure, and engineering, {Company Name} has established itself as a one-stop solution for all rubber expansion joint needs. Whether it's for bridge construction, pipeline systems, or industrial facilities, {Company Name} has the knowledge and expertise to provide the right products for any application.As a socially responsible company, {Company Name} also places a strong emphasis on environmental sustainability. The company follows eco-friendly manufacturing practices and uses recycled materials wherever possible to minimize its environmental impact. By adopting sustainable practices, {Company Name} not only contributes to environmental conservation but also sets an example for the industry.Looking ahead, {Company Name} is poised to continue its growth and expand its presence in the market. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the growing demand for rubber expansion joints in the Philippines. As the country continues to invest in infrastructure development, {Company Name} is committed to playing a key role in providing the necessary products to support these initiatives.In conclusion, {Company Name} has emerged as a prominent player in the rubber expansion joint manufacturing industry in the Philippines. With its focus on innovation, quality, and customer satisfaction, the company has earned a strong reputation and is positioned for continued success in the years to come. As the demand for rubber expansion joints continues to rise, {Company Name} is ready to meet the industry's needs and maintain its leadership position in the market.

Rubber Expansion Coupling: A Must-Have for Efficient Plumbing Systems

[News Headline]Innovative Rubber Expansion Coupling Revolutionizes Industrial Applications[Subtitle]Leading Manufacturing Company Introduces Groundbreaking Solution for Enhanced Efficiency and Durability in Mechanical Systems[City], [Date] - [Manufacturing Company], a renowned player in the industrial manufacturing sector, is set to make waves in the market with the introduction of their groundbreaking Rubber Expansion Coupling. This innovative product is designed to revolutionize various industrial applications by providing enhanced efficiency, durability, and flexibility in mechanical systems.With a commitment to delivering exceptional solutions to their customers, [Manufacturing Company] has invested considerable time and resources into research and development. The result of this investment is the Rubber Expansion Coupling, a product that is poised to set a new standard in the industry.Rubber Expansion Couplings boast an impressive array of features designed to address the challenges faced by mechanical systems in industrial environments. They offer superior vibration isolation and noise reduction, making them an ideal solution for mitigating the effects of mechanical vibrations. This feature is especially crucial in industries where precision and delicate machinery are involved.These couplings also excel in their ability to compensate for thermal expansion in mechanical systems. The rubber construction allows for flexibility, which enables the coupling to accommodate temperature variations without compromising the integrity or efficiency of the system. This critical characteristic reduces the risk of damage to equipment, extending its lifespan and reducing maintenance costs.Furthermore, the Rubber Expansion Coupling is uniquely designed to resist the detrimental effects of corrosion and chemicals. This resistance enables the coupling to withstand harsh environments, including those with high humidity or exposure to chemicals, without experiencing premature degradation. The result is a longer product life and increased reliability in demanding industrial applications."Introducing the Rubber Expansion Coupling is a major milestone for our company," said [Company Spokesperson], spokesperson for [Manufacturing Company]. "We believe this product will make a significant impact in numerous industries by providing an unmatched combination of efficiency, durability, and flexibility. It reflects our commitment to constantly push the boundaries of innovation and deliver tangible benefits to our customers."In addition to its exceptional performance, the Rubber Expansion Coupling is remarkably easy to install. With minimal downtime required, it enables customers to incorporate the coupling seamlessly into their existing mechanical systems without significant disruptions. This ease of installation further enhances its appeal as a cost-effective solution for industries seeking to optimize their operations.The Rubber Expansion Coupling is available in a wide range of sizes and configurations to cater to diverse industrial needs. This versatility ensures that customers can find the perfect fit for their specific applications. Combined with the company's dedication to providing excellent customer service and technical support, this product showcase [Manufacturing Company]'s commitment to meeting the unique requirements of its clients.In conclusion, the introduction of the Rubber Expansion Coupling by [Manufacturing Company] marks a significant milestone in the industrial manufacturing sector. The superior vibration isolation, thermal expansion compensation, corrosion resistance, and easy installation offered by this innovative product make it an ideal solution for various industrial applications. As [Manufacturing Company] continues to lead the way in delivering cutting-edge solutions, customers can look forward to a future of enhanced efficiency and durability in their mechanical systems.

Top 5 Rubber Joint Tips: Essential Insights for Better Joint Health

Title: Advanced Rubber Joint Technology Revolutionizes Industry ApplicationsIntroduction:In an era where innovation and efficiency are crucial to stay competitive, companies around the world are constantly seeking breakthrough technologies that can revolutionize their respective industries. One such technology making waves in the market is the advanced rubber joint, a versatile and reliable product that offers numerous applications across various sectors. Combining superior engineering with durability, these rubber joints provide enhanced performance and longevity, raising the bar for industry standards and redefining the possibilities for countless sectors worldwide.Rubber Joint: A Multifaceted Solution for Diverse IndustriesRubber joints, also known as expansion joints, serve as flexible connectors designed to absorb movement in pipes, tanks, and fittings, thus preventing damage and reducing stress on the overall system. The upgraded rubber joint technology, pioneered by one of the leading innovators in this field, has gained significant traction due to its outstanding features and unmatched quality.Manufactured using premium-grade rubber compounds, these joints offer exceptional resistance to temperature, pressure, and chemical corrosion, making them ideal for applications in sectors ranging from oil and gas to construction and manufacturing. With their ability to handle displacement, vibrations, and misalignment, rubber joints provide enhanced reliability and durability, ensuring smooth and efficient operations even in demanding environments.Revolutionizing Industry Applications1. Oil and Gas Sector:Rubber joints find extensive applications in the oil and gas industry, where they help to absorb vibrations and shocks caused by the flow of petroleum products, minimizing the risk of pipeline damage or leaks. By effectively accommodating thermal expansions and contractions, these joints improve the overall safety and reliability of the pipeline network.2. Construction Sector:In the construction industry, rubber joints play a critical role in absorbing structural movements caused by seismic activities, wind, or ground settlement. By allowing controlled movement, these joints prevent cracks and damages to buildings, offering cost-effective and long-lasting solutions for architects and construction engineers.3. Manufacturing Sector:Rubber joints play a vital role in manufacturing facilities by absorbing vibrations and reducing noise levels generated by heavy machinery. By minimizing the impact of these factors, rubber joints contribute to a safer working environment while improving the overall operational efficiency.4. Water Treatment Sector:In water treatment plants, rubber joints are widely used to compensate for thermal expansion and contraction in pipelines. By allowing for controlled movement, these joints prevent damage and leakage, ensuring uninterrupted water supply and reducing operational costs associated with maintenance and repairs.Leading the Industry with Innovative SolutionsThe company behind this revolutionary rubber joint technology has firmly established itself as a leader in the field. With a strong commitment to research and development, they consistently strive to deliver cutting-edge solutions that cater to the evolving needs of diverse industries. By leveraging advanced manufacturing techniques, rigorous quality control, and a customer-centric approach, they have built a reputation for excellence.Moreover, the company's dedication to sustainability is evident through its commitment to using eco-friendly materials and processes in the production of rubber joints. By prioritizing environmental consciousness, they ensure their products not only meet industry standards but also contribute to a greener future.Conclusion:The advanced rubber joint technology has emerged as a game-changer in various industries, offering unmatched flexibility, durability, and reliability. Their applications in the oil and gas, construction, manufacturing, and water treatment sectors have led to safer operations, reduced maintenance costs, and improved overall efficiency. With the company's commitment to innovation and sustainability, the future of the rubber joint industry looks promising, setting new benchmarks for quality and performance.