Exploring the Benefits of a Reliable 4-Inch Flexible Joint on the Market

By:Admin

The rapid growth and development of industries such as manufacturing, construction, and plumbing have necessitated constant improvements and innovations in various areas. One such area is pipe fitting solutions, where the introduction of the game-changing Flexible Joint 4 Inch promises to revolutionize the market. This highly efficient and versatile product, developed by the renowned company {remove brand name}, is set to dramatically improve the efficiency and reliability of pipe installations across a wide range of industries.

{Remove brand name} is a well-respected company that has been at the forefront of engineering and manufacturing solutions for industries worldwide. With a strong emphasis on quality, innovation, and customer satisfaction, their products have consistently met the highest standards in the industry. The introduction of the Flexible Joint 4 Inch is a testament to their commitment to pushing boundaries and meeting the evolving needs of their customers.

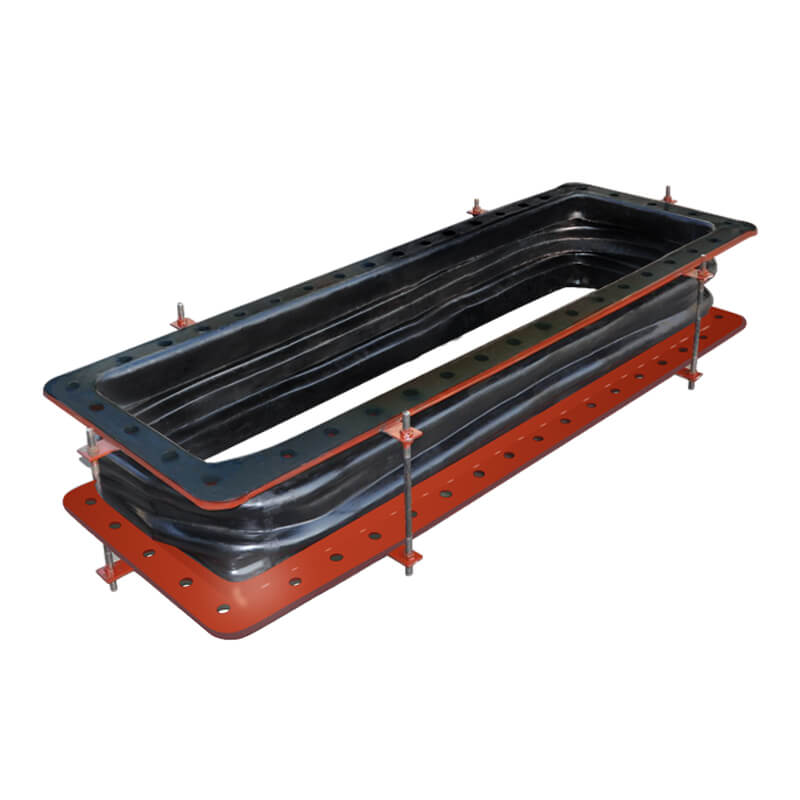

The Flexible Joint 4 Inch is a flexible pipe fitting solution that offers unmatched convenience, reliability, and durability. It is designed to provide easy and secure connections between pipes of varying sizes, materials, and angles, eliminating the need for multiple fittings and adapters. This innovation not only significantly reduces installation time and costs but also streamlines the entire process, minimizing the chances of leaks and other potential issues.

What sets the Flexible Joint 4 Inch apart from traditional pipe fitting solutions is its unique design and construction. Made from high-quality materials that exhibit exceptional flexibility and strength, this joint ensures a tight and secure connection between pipes while allowing for movement and expansion. Its ability to absorb vibrations and shocks makes it ideal for applications in industries such as HVAC, plumbing, and construction, where sturdy and reliable connections are paramount.

Additionally, the Flexible Joint 4 Inch boasts a user-friendly design that simplifies the installation process. Its innovative features, such as pre-installed gaskets and quick-connect mechanisms, enable even inexperienced installers to achieve professional-grade results. This ease of use not only saves time and labor costs but also reduces the risk of installation errors that could lead to leaks or inefficiencies down the line.

Furthermore, the Flexible Joint 4 Inch offers exceptional versatility. Its compatibility with pipes of different materials, including PVC, steel, copper, and PEX, makes it an ideal choice for a wide range of applications, from commercial buildings to residential homes. It can also accommodate pipes of varying diameters and angles, providing a flexible solution for any project size or complexity.

In terms of durability, the Flexible Joint 4 Inch surpasses industry standards. Its robust construction and high-quality materials make it resistant to corrosion, chemicals, and extreme weather conditions. This enhances its lifespan and ensures long-term reliability, reducing maintenance and replacement costs for businesses and individuals alike.

The introduction of the Flexible Joint 4 Inch is undoubtedly a game-changer in the pipe fitting industry. Its innovative design, exceptional versatility, and unmatched reliability make it the go-to solution for professionals and DIY enthusiasts alike. As industries continue to evolve and demand more efficient and cost-effective piping solutions, companies like {remove brand name} are leading the way with groundbreaking products like the Flexible Joint 4 Inch.

Company News & Blog

Experts Reveal Importance of Steel Pipe Expansion Joints for Industrial Applications

[Company Introduction] Steel Pipe Expansion Joint (Name Removed) is a renowned manufacturer and supplier of high-quality pipe expansion joints. With extensive experience in the industry, the company has built a strong reputation for delivering reliable and durable solutions for various applications. Their commitment to innovation, engineering excellence, and customer satisfaction has made them a preferred choice for a wide range of industries across the globe.[News Content]Title: Steel Pipe Expansion Joint (Name Removed) Introduces New Line of Advanced Expansion JointsDate: [Insert Date][City, State, Country] - Steel Pipe Expansion Joint, a leading manufacturer in the pipe expansion joint industry, is proud to announce the launch of its latest line of advanced expansion joints. The new product range promises to revolutionize the industry with its innovative design, improved functionality, and enhanced durability.With decades of experience in providing high-quality solutions to industries including oil and gas, petrochemical, power generation, and water treatment, Steel Pipe Expansion Joint (Name Removed) has established itself as a trusted partner for companies worldwide. The company’s commitment to delivering reliable products that meet the highest industry standards has contributed to its success and widespread recognition.The newly launched line of expansion joints showcases the company’s dedication to continuous improvement and delivering cutting-edge solutions to its customers. The expansion joints are engineered to accommodate the changing needs of various industries, ensuring optimal performance and efficiency under challenging operating conditions.One of the key highlights of the new expansion joint range is its advanced design, which allows for increased flexibility and movement capacity. The innovative design helps absorb vibrations, compensate for thermal expansion and contraction, and mitigate the harmful effects of pressure fluctuations, ultimately prolonging the lifespan of the pipeline systems.Additionally, the expansion joints are manufactured using high-quality materials, ensuring excellent resistance to corrosion, abrasion, and extreme temperatures. This guarantees longevity and minimizes maintenance requirements, resulting in cost savings for the end-users.Steel Pipe Expansion Joint (Name Removed) understands the importance of customization in meeting diverse industry requirements. To address this, the company offers tailored solutions to cater to specific project needs. Their team of experienced engineers works closely with clients to design expansion joints that precisely fit their applications, ensuring optimum performance and reliability.In line with their commitment to customer satisfaction, Steel Pipe Expansion Joint (Name Removed) provides comprehensive technical support and assistance throughout the project lifecycle. Their team of experts is readily available to offer guidance on joint selection, installation, and maintenance, ensuring a seamless and hassle-free experience for their valued customers.Furthermore, the expansion joint range adheres to all relevant international standards, such as ASME, DIN, and ISO, guaranteeing compliance with industry regulations and requirements. This reinforces the company’s dedication to manufacturing products of the highest quality and reliability.As market demand for efficient and durable pipe expansion joints continues to grow, Steel Pipe Expansion Joint (Name Removed) remains committed to meeting and exceeding customer expectations. The introduction of their new line of advanced expansion joints further strengthens their position as an industry leader, providing state-of-the-art solutions that ensure the smooth operation of critical pipeline systems.About Steel Pipe Expansion Joint (Name Removed):Steel Pipe Expansion Joint (Name Removed) is a globally recognized manufacturer and supplier of high-quality pipe expansion joints. With a strong commitment to engineering excellence, customer satisfaction, and continuous innovation, the company has become a trusted partner for industries worldwide. Their comprehensive range of expansion joints caters to a wide array of applications, ensuring optimal performance and reliability. For more information, please visit [website].Contact:[Company Name][Contact Person][Title][Address][City, State, Country][Phone Number][Email Address][Website]

Premium Viton Gasket Sheet Material for Various Applications - Available at Hunter Expansion Joints

and Viton Sheet Gasket Material.Rubber Expansion Joints: Why They are Important for Your Industrial ApplicationsRubber expansion joints, also known as compensators, are critical components of various industrial applications. They serve the purpose of accommodating thermal expansion and contraction of pipelines and ducts. Expansion joints act as flexible connectors that help absorb the movement and vibration of the pipework they connect. They are installed in piping systems to protect against stress caused by thermal expansion, vibrations, and mechanical movements. Depending on the application and operating condition, different types of expansion joints are utilized, such as rubber expansion joints. In this post, we will discuss what rubber expansion joints are, why they are essential for industrial applications, and the significance of Viton sheet gasket material in these joints.What are Rubber Expansion Joints?Rubber expansion joints are devices designed to compensate for the movement and vibration in piping and ductwork systems. They consist of flexible, molded, or fabricated elastomer materials that are reinforced with synthetic fibers or wire nets. Different types of rubber are used to manufacture these joints, such as butyl, EPDM, neoprene, nitrile, and Viton. Their elasticity, resilience, and chemical resistance make them ideal for a wide range of industrial applications.Why are Rubber Expansion Joints Important for Industrial Applications?Rubber expansion joints serve many functions in industrial piping systems. Some of these functions include:1. Absorbing VibrationsA major problem with piping systems is vibration caused by mechanical equipment, pressure surges, and fluid turbulence. Over time, vibrations can cause damage, leading to leaks, cracks, and corrosion. Rubber expansion joints help absorb the vibrations that may harm the system and neighboring equipment.2. Accommodating Thermal ExpansionPiping systems are subject to thermal expansion and contraction, especially in high-temperature environments. Without expansion joints, the increased stress on the pipes and fittings can lead to leaks, cracks, and damage to the equipment. Rubber expansion joints can accommodate thermal expansion and contraction, reducing stress on the system and the likelihood of damage.3. Preventing Transfer of NoiseRubber expansion joints help dampen the transfer of noise caused by equipment and fluid flow in piping systems. This is especially important in industrial settings where noise pollution can interfere with the work environment.The Significance of Viton Sheet Gasket Material in Rubber Expansion JointsViton sheet gasket material is a high-performance fluoroelastomer that is used in rubber expansion joints. The material's unique properties include excellent chemical resistance to acids, alkalis, and solvents, high-temperature tolerance, and low gas permeability. These properties make Viton an ideal material for sealing applications in aggressive chemical environments, such as the chemical processing industry.Viton sheet gasket material is utilized in the manufacturing of rubber expansion joints to provide an effective barrier against fluid and gas flow. The material allows the joint to maintain its sealing properties in harsh environments, ensuring that there are no leaks or spills.ConclusionRubber expansion joints play a crucial role in industrial applications to protect systems from damage caused due to thermal expansion, vibrations, and mechanical movements. Viton sheet gasket material is a critical component of these joints as it provides an effective barrier against fluid and gas flow, ensuring that there are no leaks, spills, or damage. Choosing the right type of rubber expansion joint and gasket material is essential to ensure the safety and longevity of your industrial systems. For more information on rubber expansion joints and Viton sheet gasket materials, contact Hunter Expansion Joints.

How to Prevent Pipe Damage from Thermal Expansion

As industries continue to evolve and expand, there is an increasing need for innovative solutions that can effectively address and solve problems faced during construction, maintenance, and production activities. One such solution that has been gaining increasing popularity in recent times is pipe thermal expansion. A method that concerns the force behind the expansion or contraction of materials through temperature fluctuations.One of the companies that have been leading the way in offering such innovative solutions is the renowned industry leader in manufacturing and installation of thermal expansion systems. Their technology not only delivers practical and efficient solutions but also helps to reduce operational costs, increase safety, and improve reliability.Thermal expansion happens when materials or structures expand or contract due to temperature fluctuations. For instance, when heated, a pipe expands and can either crack or leak if the expansion occurs beyond the pipe's capacity. This is where the thermal expansion system comes into play, its the ability to allow pipe expansion and contraction without undue stress, which ultimately saves the pipe from damages.The expansion of pipes is one of the significant issues that industries face in production. Thus, many companies have turned towards pipe thermal expansion solutions to increase the life span of their pipeline infrastructure systems. Construction, refinery, chemical, and other industries can benefit from the non-disruptive nature of the thermal expansion system offered by the company. The system ensures that the pipelines maintain their integrity and helps to prevent leaks and damages.Apart from reducing pipeline damages and disruptions, the thermal expansion technology also helps in the transportation of liquids through pipelines over long distances. The ability to expand or contract the pipes allows for the efficient delivery and transport of liquids and gaseous substances, which is vital in the modern industrial landscape.Additionally, the company's thermal expansion technology provides a suitable alternative to traditional pipeline insulation. Traditional insulation methods can increase energy consumption, and in turn, increase cost significantly. With pipe thermal expansion, pipes can expand and contract without undue stress while maintaining the required temperature, ultimately leading to a reduction in energy consumption.One of the significant benefits of the company's thermal expansion technology is its versatility. It is ideal for use in various pipeline infrastructure systems and applications such as underground piping, petroleum refineries, water treatment plants and many more. Additionally, the technology can function under a wide range of atmospheric and environmental conditions, thus making it an ideal solution for industries in various regions.In conclusion, the modern industrial landscape requires innovative solutions that can help to improve overall efficiency and productivity. The developmental efforts made by the company in the area of pipe thermal expansion have long term benefits, including increasing structural integrity, limiting unexpected downtime, increasing profitability, and protecting the environment. As industries continue to evolve at a rapid pace, the solution offered by the company is one of the critical drivers for industrial progress.

Rubber Flex Connectors with Flange for Secure Attachment

[Company Name] Introduces Flanged Rubber Flex Connectors: Revolutionizing the Plumbing Industry[City, Date] – [Company Name], a leading innovator in the plumbing industry, is proud to introduce their latest product line of Flanged Rubber Flex Connectors. These state-of-the-art connectors are designed to provide superior sealing and flexibility in a wide range of plumbing applications. With their innovative design and exceptional quality, these connectors are set to revolutionize the plumbing industry.Plumbing systems require reliable connectors that can withstand frequent movement, pressure changes, and varying temperatures. Flanged Rubber Flex Connectors are the perfect solution to these challenges. They are constructed using high-quality rubber that is specially engineered to be durable, flexible, and resistant to wear and tear.The key feature of Flanged Rubber Flex Connectors is their ability to accommodate misalignment and movement in plumbing systems. These connectors can handle lateral, axial, and angular movements, making them highly versatile and adaptable to different installation requirements. This flexibility significantly reduces stress on pipes and fittings, leading to improved system performance and longer service life.The flanged ends of the connectors provide a secure and leak-free connection to various plumbing components. They are available in a range of sizes and pressure ratings, ensuring compatibility with different pipe diameters and system specifications. The flanged design also allows for easy installation and maintenance, making it convenient for plumbers and contractors.In addition to their flexibility and ease of installation, Flanged Rubber Flex Connectors offer excellent resistance to chemicals, ozone, and UV exposure. This ensures their longevity and reliability, even in harsh environments. Their robust construction helps prevent leaks, vibration transmission, and noise, resulting in quieter and more efficient plumbing systems.“[Company Name] is committed to providing cutting-edge solutions that meet the evolving needs of the plumbing industry,” said [Company Spokesperson]. “Our Flanged Rubber Flex Connectors are a testament to our dedication to innovation and quality. We have utilized our expertise in rubber manufacturing to develop a product that not only addresses the current challenges faced by plumbers but also offers superior performance and reliability.”To ensure the highest level of quality control, [Company Name] subjects their Flanged Rubber Flex Connectors to rigorous testing and inspection procedures. These connectors are manufactured in state-of-the-art facilities, utilizing the latest technology and adhering to strict industry standards. As a result, customers can have confidence in the durability and performance of these connectors.Plumbers, contractors, and plumbing system designers can now rely on [Company Name] for the highest quality Flanged Rubber Flex Connectors. These connectors can be used in a wide range of applications, including HVAC systems, water treatment facilities, industrial piping, and commercial buildings. With the ability to handle challenging installation conditions and maintain excellent sealing properties, these connectors offer a viable solution for any plumbing project.[Company Name] is a leading provider of innovative plumbing solutions, dedicated to improving the efficiency and reliability of plumbing systems. With their commitment to quality and innovation, they continue to be at the forefront of the industry. The introduction of Flanged Rubber Flex Connectors reaffirms their ability to provide cutting-edge products that meet the demanding needs of the plumbing industry.For more information about [Company Name] and their Flanged Rubber Flex Connectors, please visit [company website] or contact [contact details].###About [Company Name][Company Name] is a renowned innovator in the plumbing industry, offering a wide range of high-quality products and solutions. With a commitment to excellence, they continue to drive advancements in the industry, providing reliable and efficient solutions to their customers. [Company Name] takes pride in their ability to understand and meet the unique requirements of different plumbing projects.

BMW 528i Propeller Shaft Rubber Flex Disc Coupling Joint - 96mm, 6-Bolt x 12mm, 30mm Thickness SKU#(s) GAB01-017, 26117511454, 261122226842

for optimal search engine results. When it comes to your BMW 528i propeller shaft, one important component to pay attention to is the flex disc or coupling joint. This piece of machinery is responsible for transferring the power from the engine to the wheels. Without it, your vehicle’s overall performance and handling would suffer significantly.The good news is that Fort Wayne Clutch & Driveline has got you covered with their Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842. This product is designed using high-quality rubber material, ensuring durability and longevity.The 96mm size of the flex disc is crucial to fit onto your BMW 528i propeller shaft. It features a 6-bolt x 12mm design, making installation easy and straightforward. Additionally, this model has a thickness of 30mm, which further adds to its sturdiness and resilience.It’s important to note that the flex disc or coupling joint is a component that needs to be checked regularly. Over time, the rubber material can wear out due to exposure to friction, heat, and other environmental factors. If not addressed properly, it can lead to severe damage to the propeller shaft and overall vehicle safety.That’s why we highly recommend that you replace your old or worn-out flex disc with a new and reliable product like the Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint from Fort Wayne Clutch & Driveline. This will not only ensure that your vehicle runs smoothly, but it will also give you peace of mind while you’re on the road.In conclusion, the flex disc or coupling joint is a crucial component in the functioning of your BMW 528i propeller shaft. Fort Wayne Clutch & Driveline’s Flex Disc - 96mm - BMW 528i Propeller Shaft Rubber Flex Disc Guibo Coupling Joint, SKU#(s) GAB01-017, 26117511454, 261122226842, is a reliable and durable product that will ensure your vehicle runs smoothly and efficiently. So, don’t wait any longer, and replace your worn-out coupling joint today with a brand new one!

Free PNG and SVG Pipe Joint Illustrations and Vector Images in 45 Styles

Pipes are an essential part of our everyday life, from carrying water to transporting gas. However, these pipes cannot function without joints that connect them together. Joints for pipes come in various shapes and sizes, and they are essential for the seamless functioning of our plumbing systems.One common type of joint for pipes is the clip joint. A clip joint is a joining method that involves using a clip or clamp to secure two pieces of pipe together. Clip joints are easy to install and do not require any special tools or expertise. They are commonly used in household plumbing applications such as sink and shower installations.Clip joints come in various materials, including PVC, copper, and stainless steel. These materials are chosen based on the application and the environment in which the joint will be used. For example, PVC clip joints are suitable for low-pressure applications such as drainage systems, while stainless steel clip joints are ideal for high-pressure applications such as gas pipelines.To ensure the proper functioning of clip joints, it is crucial to choose the right size and type of clip for the pipe. Improperly sized or mismatched clips can result in leaks, which can lead to water damage and flooding. It is also important to use high-quality clips from reputable manufacturers to ensure durability and longevity.When installing clip joints, it is essential to follow proper installation procedures. This includes ensuring that the pipes are clean and dry, and that the clip is tightened to the manufacturer's specifications. Failure to follow proper installation procedures can result in leaks, which can compromise the overall integrity of the plumbing system.In summary, joints for pipes, such as clip joints, are essential for the proper functioning of our plumbing systems. It is crucial to choose the right size and type of clip for the pipe and to follow proper installation procedures. With the right joints and installation techniques, we can ensure the seamless functioning of our plumbing systems and avoid water damage and other plumbing issues.Keywords: Joints for Pipes, Clip joints, PVC clip joints, Copper clip joints, Stainless steel clip joints, Plumbing systems, Pipe Joint Clipart Illustrations & Images, PNG, SVG.

Rubber Expansion Bellows Dimensions: Choosing the Right Fit for Your ApplicationWhen it comes to ensuring the safe and efficient operation of pipelines and machinery, rubber expansion joints and bellows play a crucial role. These flexible elements help compensate for movements, absorb vibrations, and reduce noise, ultimately protecting equipment and extending its lifespan. As premier suppliers of rubber expansion joints in the UAE, we understand the diverse needs of our clients and provide a wide range of options to meet those needs.One of the critical factors to consider while selecting rubber expansion joints or bellows is their dimensions. Accurate dimensioning ensures a proper fit, preventing leaks, pressure imbalances, and potential damages to the system. In this blog, we will explore the importance of rubber expansion bellows' dimensions and ways to choose the right fit for your application.Understanding Rubber Expansion Bellows DimensionsRubber expansion bellows are designed to accommodate various movements caused by thermal expansion, vibrations, pressure changes, or misalignments between pipes and equipment. The dimensions of expansion bellows play a significant role in determining their performance and ability to withstand these movements.Diameter:The outer and inner diameters of rubber expansion bellows directly impact their functionality. The outer diameter should match the respective pipe size, ensuring proper alignment and connection. On the other hand, the inner diameter determines the flow capacity of the system. It is crucial to select an expansion bellows with an inner diameter that matches the flow requirements of your specific application.Length:The length of rubber expansion bellows refers to the distance between the flange faces when the bellows is fully extended or compressed. This dimension is crucial to ensure the bellows' ability to absorb movements without overstressing or compressing beyond its designed limits. Determining the correct length is crucial to maintain the overall integrity and performance of the system.Movement Capability:The movement capability of rubber expansion bellows is closely linked to their dimensions. It is essential to consider the anticipated axial, lateral, and angular movements that the bellows will experience in your application. These movements may arise from changes in temperature, pressure, or vibrations. Choosing bellows with appropriate dimensions and movement capabilities ensures the desired flexibility and durability of the system.Thickness:The thickness of rubber expansion bellows determines their resilience and resistance to pressure and external forces. Thick-walled bellows provide better resistance to external impacts but may reduce their flexibility. Conversely, thin-walled bellows may provide increased flexibility but may compromise their long-term durability. Selecting the right thickness requires careful consideration of the specific operating conditions and the required balance between flexibility and durability.Pressure Ratings:The dimensions of rubber expansion bellows also contribute to their pressure ratings. Components of different dimensions, such as wall thickness and bellows length, have varying pressure resistance capabilities. It is essential to choose bellows with appropriate pressure ratings to ensure safe and efficient operation within your system.Choosing the Right Rubber Expansion Bellows DimensionsTo ensure optimal performance and reliability, consider the following factors when selecting rubber expansion bellows dimensions for your application:1. Understand the application requirements and operating conditions, including temperature fluctuations, pressure variations, and the types of movements the bellows needs to accommodate.2. Consult with experts in the field, such as our knowledgeable team, who can guide you in selecting the appropriate dimensions based on your specific needs.3. Evaluate the compatibility of the selected dimensions with your existing system components, ensuring a proper fit and connection.4. Regularly inspect and assess the performance of the rubber expansion bellows over time to ensure they continue to meet the system's needs adequately.ConclusionRubber expansion bellows are essential components in numerous industrial applications, providing flexibility and protection to pipelines and machinery. By carefully considering dimensions, such as diameter, length, movement capability, thickness, and pressure ratings, you can select the right rubber expansion bellows for your specific application.As the premier supplier of expansion joints in the UAE, we offer an extensive range of rubber expansion bellows, utilizing our expertise to ensure the perfect fit for your system. Contact us today to explore our extensive selection and benefit from our knowledgeable team's advice for optimal performance and longevity of your system.

The Advantages of Bellows Type Expansion Joints for Your Industrial Applications

A leading manufacturer of Bellows Type Expansion Joints (brand name removed) has recently been making headlines for its innovative approach to the design and production of these important industrial components. With a long history of expertise in the field, this company has built a reputation for excellence and reliability, providing essential solutions to a wide variety of industries and applications.One of the key factors behind the company's success is its commitment to research and development. By constantly exploring new materials, techniques, and applications, this manufacturer has been able to continuously improve the quality of its products, making them more durable, efficient, and cost-effective than ever before. This dedication to innovation has also allowed the company to expand its offerings, providing custom solutions for unique and challenging requirements.Another strength of this manufacturer is its focus on customer service. With a team of highly skilled and knowledgeable professionals, the company is able to provide expert support through every stage of the purchasing process. Whether it's helping clients to choose the right expansion joint for their needs, tracking delivery status, or providing advice on installation and maintenance, the team is always available to offer helpful insights and assistance.Of course, the real proof of a product's quality is in its performance, and that's where this manufacturer really stands out. With a wide range of sizes, materials, and configurations available, these Bellows Type Expansion Joints can handle even the most demanding applications. From high-temperature environments to corrosive chemical processing, these components provide reliable performance and long service life, greatly reducing downtime and maintenance costs for customers.Beyond these practical benefits, there are also significant environmental advantages to be gained from incorporating Bellows Type Expansion Joints into industrial systems. By accommodating the thermal expansion and contraction that occurs in piping networks, these components help to prevent stress, leaks, and other damage that can lead to hazardous spills or emissions. They also help to improve energy efficiency by reducing friction and turbulence in the system, which means less wasted energy and lower emissions. As a result, choosing high-quality expansion joints isn't just a matter of economics or practicality – it's also an important step toward sustainable and responsible operations.All of these factors combine to make the Bellows Type Expansion Joints from this manufacturer an excellent choice for a wide variety of industrial applications. Whether you're working in the chemical, petrochemical, power generation, or HVAC sectors, these components provide reliable performance, cost savings, and environmental benefits that simply can't be matched by other solutions.With a long track record of success, a strong focus on R&D and customer service, and a commitment to sustainability, this manufacturer is poised to continue leading the way in the expansion joint industry for years to come. If you're looking to improve the performance and safety of your industrial systems, consider making these high-quality components a part of your plan – they just might be the perfect solution for your needs.

Flexible Joint for PVC Pipes - Suppliers and Manufacturers in China - Hisupplier.com

Flexible Joint For PVC Pipe: Revolutionizing the Plumbing IndustryThe plumbing industry has seen a lot of innovation in recent times, particularly with the introduction of new and improved materials for pipes. PVC pipes have especially gained popularity in the plumbing industry due to their durability, affordability, and easy installation.However, even with PVC pipes, leaks can occur if the joints are not properly installed or if they are exposed to external forces. To counter this issue, manufacturers have introduced flexible joints for PVC pipes to improve the integrity and reliability of the plumbing system.What is a Flexible Joint for PVC Pipe?A flexible joint for PVC pipes is a specialized connection that is installed between two PVC pipes and allows for movement between them. It enables the pipes to expand and contract with temperature changes, thus minimizing the risk of leaks or breakages due to pressure buildup.Flexible joints are easy to install and can be used for both above-ground and underground applications. They come in various sizes and shapes, making them suitable for different types of PVC pipes and plumbing applications.Benefits of Flexible Joint for PVC PipeImproved durability: Flexible joints can withstand external forces and pressure changes resulting from temperature fluctuations, minimizing the risk of leaks or pipe breakages.Reduced maintenance costs: Flexible joints minimize pipe replacement and maintenance costs, which can add up over the years.Easy installation: Flexible joints can be installed quickly and easily, reducing installation times and labor costs.Versatility: Flexible joints can be used for both above-ground and underground plumbing applications, making them highly versatile.Minimized noise: Flexible joints help to absorb vibrations and noise generated by the plumbing system, making them ideal for use in buildings and structures with noise-sensitive occupants.Enhanced safety: Flexible joints minimize the risk of injury or damage to property resulting from pipe bursts or leaks.ConclusionFlexible joints for PVC pipes have revolutionized the plumbing industry by providing a reliable, cost-effective, and easy-to-install solution for pipe connections. They offer numerous benefits such as improved durability, reduced maintenance costs, versatility, minimized noise, and enhanced safety.If you're looking to install a new plumbing system or replace an existing one, consider incorporating flexible joints for PVC pipes into your plans. They are an excellent investment that will save you time and money in the long run.

High-Quality Rubber Hoses for All Industries - Find Top Manufacturers and Suppliers on Alibaba.com

Rubber Pipe: The Ultimate GuideWhen it comes to transporting fluids and gases, having the right type of pipe is crucial. One type of pipe that has proved to be versatile and reliable is a rubber pipe. In this blog, we will delve deeper into rubber pipes, their types, and their uses.What is a Rubber Pipe?A rubber pipe is a flexible pipe made from rubber. These pipes can withstand high pressures and temperatures and are used to transfer oil, water, and other fluids. Rubber pipes are also used in various other industries such as automotive, mining, and chemical processing.Types of Rubber PipesThere are various types of rubber pipes, each with its specific use. Here are the commonly used types of rubber pipes:1. Silicone Rubber PipeSilicone rubber pipes are used in high-temperature applications as they can withstand very high temperatures. They can also withstand extreme cold temperatures and are used in medical, food, and beverage industries.2. Nitrile Rubber PipeNitrile rubber pipes are resistant to oil and gasoline and are used in fuel systems and hydraulic systems. They are also used in the chemical industry, where the transfer of chemicals is needed.3. Natural Rubber PipeNatural rubber pipes are flexible and have excellent elasticity. They are used in the automotive industry, where they are used in brake systems and the transport of other fluids.4. EPDM Rubber PipeEPDM (Ethylene Propylene Diene Monomer) rubber pipes are synthetic rubber pipes that are resistant to weather, ozone, and sunlight. They are used in the automotive industry, where they are used in cooling systems and in the construction of buildings.Uses of Rubber PipesRubber pipes are used in various industries and applications, including:1. Automotive industryRubber pipes are used in the automotive industry to transport various fluids such as oil, fuel, and coolant. They are also used in air filters, brake systems, and power steering systems.2. Medical industrySilicone rubber pipes are used in the medical industry for transporting fluids and gases. They are used in applications such as blood transfusions, dialysis, and drug delivery.3. Food and Beverage industrySilicone rubber pipes are used in the food and beverage industry. They are used to transfer food products such as milk and juice.4. Chemical industryRubber pipes are used in the chemical industry to transport various chemicals. They are used in applications such as acids, alcohol, and petroleum.Advantages of Rubber PipesHere are the advantages of using rubber pipes:1. Resistance to high temperatureRubber pipes can withstand high temperatures, making them ideal for use in high-temperature applications.2. Cost-effectiveRubber pipes are relatively cheaper compared to other pipe materials. This factor makes them cost-effective, especially for large-scale applications.3. FlexibilityRubber pipes are flexible and can bend without breaking. This factor makes them ideal for applications where pipes need to be flexible.4. DurabilityRubber pipes are durable and can withstand wear and tear over time. This factor ensures that they last for an extended period, thus reducing the need for frequent replacements.ConclusionRubber pipes are a versatile and reliable type of pipe that can be used in various industries and applications. With a wide variety of types available, including silicone rubber pipe, nitrile rubber pipe, natural rubber pipe, and EPDM rubber pipe, there is a rubber pipe for every application. Rubber pipes offer advantages such as resistance to high temperatures, cost-effectiveness, flexibility, and durability, making them an excellent choice for various applications.So, whenever you need a pipe that can withstand high temperatures, resist chemicals, and be flexible, think of rubber pipes. They are the ultimate solution for your piping needs.